PLA 3D printed parts in an engine bay

Mr Whippy - 16/4/25 at 09:41 PM

Hi,

Now I know right away I'm going to get told I'm dumb, but hear me out.

My old car didn't come with an air filter, yes in Ye olde days they thought it was an optional extra despite the roads being a dusty mess.

However I'm not that brave and so decided to fit one, but getting one for that period was harder/expensive than expected, so in the end I decided

to just print it. At first I thought ABS or PETG was the only way to go but a scan with my IR thermometer didn't show any temps much near 50 degs

even after a long run through the city traffic so I quickly printed a very simple one as a test and checked to see how it faired up. After that

success, I make a bigger better one with plenty of foam as the filter. I'm pleased to say after several hundred miles it's doing great and

never once seems to get very hot despite being located directly above the exhaust. I still have to get around to painting it but am really happy with

this lightweight filter.

So is normal PLA filament ok for engine bays, well yes it's fine, I'd say the rule to use is if you can still touch it then PLA will cope.

Oh and all in, this filter cost me about £8 to make

Cheers.

Slimy38 - 17/4/25 at 07:05 AM

Good design and implementation, I like that. I have to admit my 3D prints have been with PETG, as my first experience with PLA did fail. It was a

phone holder in the car, and while it didn't turn to goo, there was enough heat in the cabin to deform it to a point where my phone didn't

fit. You should be fine with your housing though, at worst you might find your screw holes might not perfectly line up after a few years of warming

and cooling.

PETG for me has an added benefit though, on top of the heat resistance. I find it much easier to print, its bed adhesion is far higher than I could

ever achieve with PLA so I'm getting far fewer failed prints. It's not any more expensive either, for the basic colours I get it at more or

less the same price I used to pay for PLA.

If you ever get round to painting it though, can you post your results? Painting is one thing I've failed at, I just cannot find a paint that

stays on and maintains a decent surface. Admittedly I'm limited to brush paints which probably puts me at a disadvantage, but having one that

stays attached would be a good start!

loggyboy - 17/4/25 at 08:27 AM

PLA is susceptible to heat, shrinkage and moisture. I give that 6months before its a very different shape.

jacko - 17/4/25 at 10:49 AM

I donít know anything about 3d printing but I think you have made a fantastic job and it looks right for the age of your car

scudderfish - 17/4/25 at 12:23 PM

I had a PLA phone mount wilt as well. I reprinted it in PETG and it has survived several years now.

Drive the car and see what happens. If it deforms, print another  I recently upgraded to a printer that can do ABS specifically so I don't

have to worry so much about heat (after watching Bizzle's videos), but if it works for you then it works.

I recently upgraded to a printer that can do ABS specifically so I don't

have to worry so much about heat (after watching Bizzle's videos), but if it works for you then it works.

[Edited on 17/4/25 by scudderfish]

gremlin1234 - 17/4/25 at 12:49 PM

looks good, if it does fail, at least you have a good template for printing another in a more robust medium.

hey that's exactly what rapid prototyping is

Mr Whippy - 17/4/25 at 01:06 PM

quote:

Originally posted by loggyboy

PLA is susceptible to heat, shrinkage and moisture. I give that 6months before its a very different shape.

Well we'll see and I'll post photos at the end of the year. I watched tests done on YouTube to see how bio-degradable PLA actually was,

turned out to totally not degradable and nothing touched it.

As above it's an interesting test and if it fails, then I'll just run off another, tbh it's so cheap I might just consider it a

replaceable item.

Thanks for the complements.

David Jenkins - 17/4/25 at 05:59 PM

PLA might be a bit iffy over time, especially if it gets warm under the bonnet in summertime, so ABS would be a better option - but that's a

total PITA to print as it likes to warp and split while it's printing. It also requires much higher temps during the printing process.

If the design works, and you can't get a 'proper' filter holder, you might consider one of the 3D printing agencies who will do a

magnificent job in the sorts of materials that really aren't easy on a home printer. Can be a bit expensive, but maybe not as much as you think.

Worth getting a quote anyway.

For example, https://www.3dpeople.uk/

I have no experience of this company, but I have used similar places in the past. Print quality is usually exceptionally good, and can be done in

tricky materials such as nylon, ABS, ASA, or similar.

It all comes down to a balance of how how much you need a good part v. how much you are prepared to pay for it.

Benzine - 17/4/25 at 10:55 PM

This is brilliant! I have a soft spot for anything old. What's the suspension like on this? Lever arm or friction dampers?

David Jenkins - 18/4/25 at 09:45 AM

I don't know if you're aware, but most (all?) plastics used in 3D printing have what is called a "glass transition temperature",

which is where the material loses dimensional stability.

LINKY.

Although PLA needs an extruder temperature of around 200C to make the item, its glass transition temp is 55C - 60C, and you'll easily reach that

under the bonnet on a hot sunny day.

Mr Whippy - 18/4/25 at 11:43 AM

Well maybe the temperatures are a bit lower than you might expect. I've just come back through the city with 2 kids & a dog + a heap of

shopping in the boot and here's the temp of the filter when I opened the bonnet, hardly anything really.

Mr Whippy - 18/4/25 at 11:50 AM

quote:

Originally posted by Benzine

This is brilliant! I have a soft spot for anything old. What's the suspension like on this? Lever arm or friction dampers?

There the lever arm type, the friction ones went out of favour about 10 years before. Ride is bouncy at best, however it floats over cobbles!

PAULD - 19/4/25 at 02:06 PM

Nice work.I have not long had a printer (a creality k1c) for my grandson and i to use. on his schools recommendation we have been using Tinkercad

which is fine but limited. Could you tell me which cad you are using please, and the cost.

Slimy38 - 19/4/25 at 04:49 PM

quote:

Originally posted by PAULD

Nice work.I have not long had a printer (a creality k1c) for my grandson and i to use. on his schools recommendation we have been using Tinkercad

which is fine but limited. Could you tell me which cad you are using please, and the cost.

While I can't speak for Mr W, I'm using Onshape which is the best price of all (free!!). It has some 'quirks' particularly because

it's used in a browser so some controls aren't intuitive, but it pretty much does everything I used to do with Fusion but without the

hassle.

Mr Whippy - 19/4/25 at 08:13 PM

quote:

Originally posted by PAULD

Nice work.I have not long had a printer (a creality k1c) for my grandson and i to use. on his schools recommendation we have been using Tinkercad

which is fine but limited. Could you tell me which cad you are using please, and the cost.

Hi, yes this was done on Tinkercad which like you said is limited but very quick for simple things (although you'd be surprised what you can do

when you know how to use it). I have been doing more complex things on Blender or using both with blenders sculpting mode to add further details or

surface effects to parts for my model ships I'd first created in Tinkercad. Blenders fine but it is a very complex tool to start off with but it

is also free. I also have Onshape but have not had the chance to use it much and it's yet another thing to learn.

It really depends on what you will be creating as to what tool to use. Blenders sculpting mode is really good fun and there are a lot of tutorials on

Youtube. I've downloaded models of the web, dismantled them in Blender, hacked, changed and added to them, stuck them back together and then

printed them just as I wanted, it's quite amazing what you can do.

Personally I started off very simple with a little baby Yoda for the kids, then went for more and more complex models that pushed my ability's,

it's been hard going and not everything worked out but now I'm building things I'd have never thought possible.

Benzine - 19/4/25 at 10:00 PM

quote:

Originally posted by Mr Whippy

There the lever arm type, the friction ones went out of favour about 10 years before. Ride is bouncy at best, however it floats over cobbles!

Nice. I'm a scrapyard regular and I had the amazing find recently of a pair of Armstrong lever arm dampers. Someone must have been having a clear

out of a shed of a dearly departed as it was all just sat in a pile. £10 for the pair. Trouble is I want to 'reclock' the arms. I found a

pdf manual and apparently they need 30 tons to pull off!

Mr Whippy - 20/4/25 at 09:32 AM

quote:

Originally posted by PAULD

Nice work.I have not long had a printer (a creality k1c) for my grandson and i to use. on his schools recommendation we have been using Tinkercad

which is fine but limited. Could you tell me which cad you are using please, and the cost.

I know Tinkercad at first does not seem very powerful, however with some patience and practice it is actually quite good and totally ideal for kids,

these are some of the 60+ build areas where I have been designing the hundreds of parts for my model ships etc and if kids are beyond that, then

I'm very impressed. I'd suggest keep them using Tinkercad especially if the school is also using it.

[Edited on 20/4/25 by Mr Whippy]

tims31 - 20/4/25 at 09:57 AM

Anything for mine, I always use ASA. Its copes with heat better than PLA and is more stable to UV light. I know its under the bonnet but I would still

recommend ASA for that.

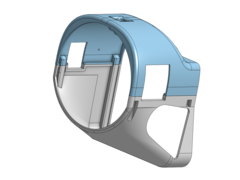

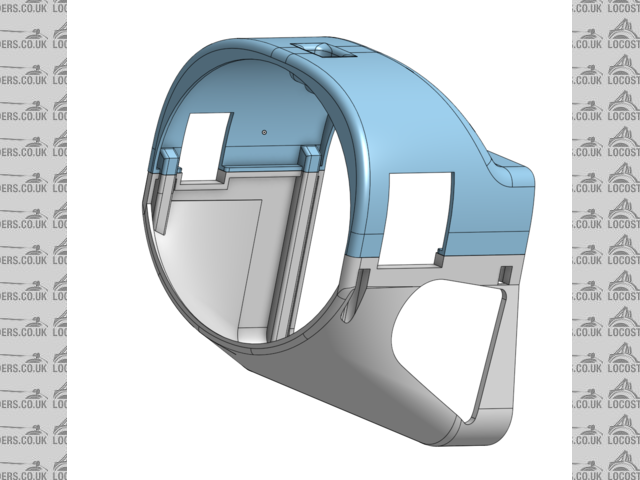

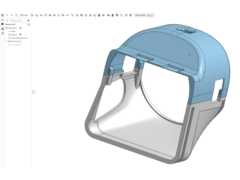

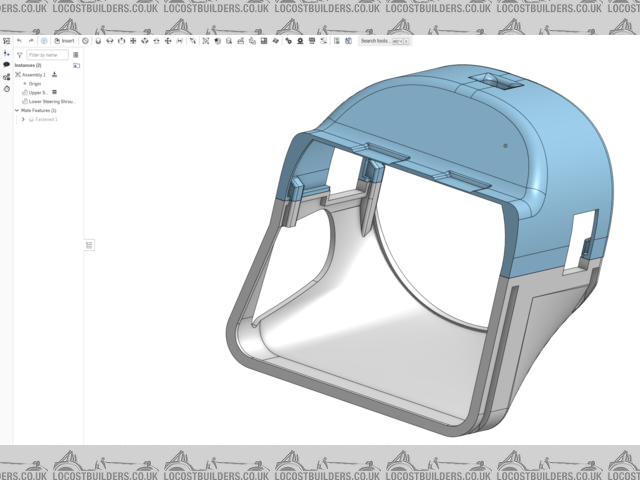

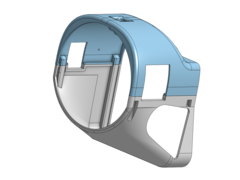

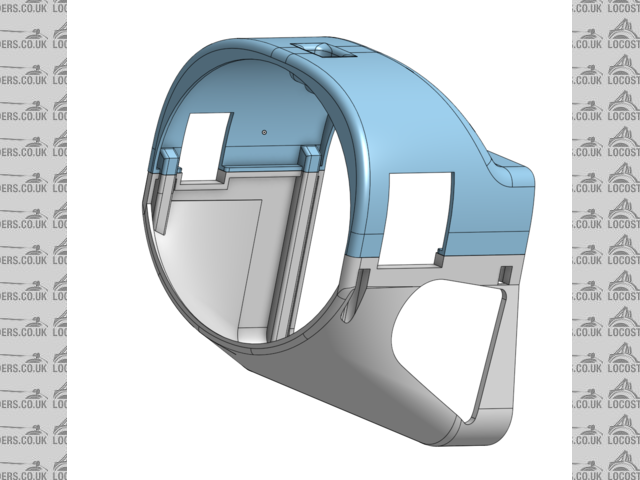

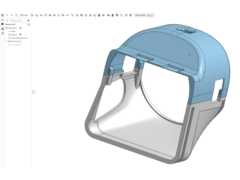

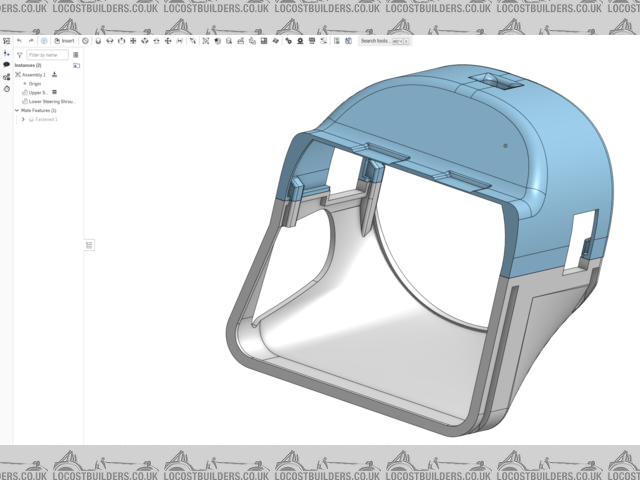

I have made a Steering suround for my Sierra column and stalks and also one for my Digi dash.

In the processs of making clamps for my high level barke light. All my stuff is designed in Onshape which is free to use and quite easy to pick up.

I would recommend looking at the tutorials by TooTallToby on youtube. He has a whole series from starting to use Onshape and takes you through lots of

the tools and ways to design parts. Very useful when starting out.

[youtube]mdauyI8Dc_0&list=PLzMIhOgu1Y5dY8DD5vnOPJ0a3d8F2TWHe[/youtube]

SteeringShroud

Description

[Edited on 20/4/25 by tims31]

[Edited on 20/4/25 by tims31]

[Edited on 20/4/25 by tims31]

[Edited on 20/4/25 by tims31]

[Edited on 20/4/25 by tims31]

Mr Whippy - 20/4/25 at 11:07 AM

Yes nice models. Interesting, I'd not even come across ASA before, not much more in cost to PLA and sounds better than ABS, however note -

"Due to its heritage, ASA still retains many of the same printability drawbacks that are seen with ABS. Warping is still a consistent issue that

you need to account for, as well as the potentially dangerous fumes that the plastic emits during printing, due to the presence of Styrene."

So I hope you have the windows open when you use it.

[Edited on 20/4/25 by Mr Whippy]

tims31 - 20/4/25 at 12:16 PM

My Printer is in an enclosure in my Garage so no worries about the fumes but I can't say I have noticed it too much when printing. The enclosure

stops drafts so I have never had any issues with the model warping off the bed.

scudderfish - 21/4/25 at 07:00 AM

quote:

Originally posted by tims31

My Printer is in an enclosure in my Garage so no worries about the fumes but I can't say I have noticed it too much when printing. The enclosure

stops drafts so I have never had any issues with the model warping off the bed.

Do you have files for that you'd be willing to share? I could do with something like that (albeit shorter) for my Fury.

Regards,

Dave

PAULD - 21/4/25 at 09:49 AM

Thanks for your advice chaps, I've obviously got a lot to learn in tinkercad.

tims31 - 21/4/25 at 12:25 PM

quote:

Originally posted by PAULD

Thanks for your advice chaps, I've obviously got a lot to learn in tinkercad.

For making parts, I would definately recommend trying Onshape. Have a look at the video series by Too Tall Toby I linked. He is really good at

teaching and the beauty of that system is that it is all browser based so no worries about the power of you machine, also it is free to use.

https://youtu.be/u4UCGiDpp-o?si=LZlf8MLQdy67LBeZ

tims31 - 21/4/25 at 12:27 PM

quote:

Originally posted by scudderfish

quote:

Originally posted by tims31

My Printer is in an enclosure in my Garage so no worries about the fumes but I can't say I have noticed it too much when printing. The enclosure

stops drafts so I have never had any issues with the model warping off the bed.

Do you have files for that you'd be willing to share? I could do with something like that (albeit shorter) for my Fury.

Regards,

Dave

I've sent you a U2u

What file type do you want?