Originally posted by spegru

I know there are a number of threads on this subject but so far Ive not been able to get my AJ30 running properly:

I'm using a MotorSport Electronics ME360 ECU

First Question - Trigger Offset: THE ECU needs to know what angle the crank shaft sensor is at and it seems that the AJ30's is not at TDC. Nor are there any markings on the front pulley.

Looks like it is 50 degrees btdc

spegru - 8/11/24 at 02:30 PM

Interesting.

I suppose this is MegaSquirt/Jolt? I also assume you are using the built in sensor, not an external sensor/wheel?

This Setting in the ME360 MEITE setup software is degrees after TDC so my 302 figure corresponds to 58deg BTDC, which is 8 degrees different to your

figure.

That may not matter - if it's all taken care of in the timing tables, which presumably could be 8 degrees different

On the other hand, MSE have downloaded an initial timing setup to me that may or may not use that same offset (they didnt have a figure available for

the AJ30)

I wonder what would happen if I change it to 310?

hmm thanks

[Edited on 8/11/24 by spegru]

MikeR - 8/11/24 at 03:43 PM

Are you both triggering on the same tooth edge - the teeth edges are 10 degrees apart so you could in reality be 2 degrees different.

spegru - 8/11/24 at 06:43 PM

Oh dear I actually dont know the answer to that important question.

As much as 10 degrees?! I am surprised its as much as that with the internal teeth (or whatever they are)

Certainly 2degrees would be within margin of error

The thing is running so roughly that Ive been trying everything without success and it makes little difference so far

This afternoon I even tried altering to 310 ATDC to match the 50 BTDC mentioned above and even that made no real difference

And now I cant be sure what I was using to get the offset in the first place!

I shall have to go back and check it all again no doubt.

In the mean time I suspect a faulty crank sensor so Ive got one on order..

Thanks for those comments!

spegru - 12/11/24 at 08:11 PM

This afternoon I took delivery of a new crank sensor so I went back to look at this again.

One of the problems I am having is uncertainty about the polarity of the connector, especially as I am not currently using the proper plug as

it's broken. It appears to be the same as for Cam sensors but different to Ford 4 Cylinder Duratec sensor plugs (the AJ30 is really a Ford

Duratec v6).

I am guessing that could be a Mazda type due to its parentage? My Jaguar S Type Wiring diagram doesnt help because it just shows what pin is

connected to what with no - VR+/- etc. For now I am using miniature spade connectors directly onto the sensor. I suspect the pins are numbered left to

right with the tag side upward?

Bear in mind that are no plug leads so I've had to rig up an extension with a plug lead from another car in order get my timing light working!

With all that in mind I got the following

With VR+ connected to the left sensor pin ( clip side upward) my timing light syncs with TDC as follows

1, 285deg ATDC (75 BTDC) - Falling edge trigger

2. Timing light fails to flash with Rising edge trigger

VR+ on the right

1. 280deg ATDC (80 BTDC) - Falling edge trigger

2. 285deg (75 BTDC) - Rising edge trigger (NB the 5deg difference)

Because this didnt line up with my previous 305 figure I checked my TDC mark - but that hardly changed. My new marks are closer to the pointer,

reducing a bit of paralax error though. I then retested as follows

VR+ on the left

1. 290 ATDC (70 BTDC) - Falling edge

2. Timing light not working - Rising Edge

VR+ on the right

1. 290 ATDC (70 BTDC) - Rising edge

2. 285 ATDC (75 BTDC) - Falling edge

I guess this tallies with a tooth that is 5 degrees wide and that the different wiring option converts rising to falling etc.

The only explanations why I am seemingly nowhere near my previous 305 ATDC is that I have a new Sensor and maybe reduced a bit of error - but so

much?!

I note that the screenshot above specified 50deg, Rising edge and I am well away from that. This is an early AJ30 and I know that later ones as used

in the Jaguar XF are visibly different in the timing chain area so maybe that's why?

As ever any help appreciated - connector type and pin numbers especially

[Edited on 12/11/24 by spegru]

spegru - 13/11/24 at 12:48 PM

Followup on this.

I've just noticed that not only the Crank & Cam sensors but also the Coil on Plug (COP) devices all have the same type of plug!

It's therefore possible that the correct plug is this one:

Ebay

link

Although these are for a 4cyl Duratec they do look the same so Ive ordered some

Also from looking at COP No1 and the Jaguar wiring diagram for the ignition coils:

a) Pin 1 is on the left as you look at the socket on the device with the tag/grooves upward (as I thought)

b) Pin 2 is COP 12v, and ECU COP Signal is on Pin 1.

And from the Jaguar wiring diagram for the Cam sensors:

CMP1 pin 2 is a common ground whereas CMP2 pin 1 is that common ground! which seems a bit bizarre because it implies that the sensors dont care which

way round they are wired (but does it invert expected the cam pattern?

Some of you guys have got this engine running so

help appreciated etc!

Esp Crank polarity and did you sync Cams?

[Edited on 13/11/24 by spegru]

spegru - 16/11/24 at 01:05 PM

Duh!

I just realised that when I did those recent ~285deg ATDC crank sensor offset measurements, the ECU was probably putting in its own Advance figure for

turnover!

So now I need to measure again.

Certainly a better explanation for the discrepancy than fitting a new sensor

[Edited on 16/11/24 by spegru]

[Edited on 16/11/24 by spegru]

spegru - 16/11/24 at 03:01 PM

Indeed. That error was definite

So now with slightly easier to read timing marks and and VR+ on the right (looking into the sensor with clip/ridges upward) we have TDC timing of:

300 deg ATDC (60 BTDC), using rising edge trigger

295 deg using falling edge trigger

I'll be using the Rising edge setting for now

This is a 300deg ATDC/ 60deg BTDC Crank Sensor Offset

spegru - 17/11/24 at 12:39 PM

In fact those Duratec 4 cylinder COP connectors do not fit - either the Jaguar AJ30 COPs or the Crank/ cam sensor. Very similar, but different.

So those will be going back then

[Edited on 18/11/24 by spegru]

mgb281 - 19/11/24 at 08:47 PM

If you can wait a week or so I am about to buy a 2.1V6 engine and providing the pallet company does its work then you can have both the sensor and the

plug with a length of wire FOC. I am only buying it for a mock up so don't need the wiring, sensors etc. This is assuming that they fit the

earlier S type engine. I bought an ex Rocketeer ME442 with a Rocketeer loom, strangely the VVC, an O2 sensor or knock control was never included in

the loom, hopefully I will have mine running next summer

By the way the Jaguar shares no parentage with the Mazda engine. The Ford/Jaguar engine was an abandoned Porsche design which was bought by Ford,

further development was done by Cosworth before being put into production at Ford's Cleveland Plant. It also shares some detail with the SHO

engine developed by Yamaha for Ford, there was actually a 60 degree V8 version of the SHO engine

mgb281 - 19/11/24 at 09:16 PM

pre 2002.5 engines used two pin COPS later ones used four pin COPS have you got plugs for the later engine?

spegru - 20/11/24 at 09:22 PM

Thanks for the offer mgb281. It could come to that if yours are the same. I do still have an original loom but it appears to very poorly screened so

ive set up some external screened cables.

It is an early '99 engine with 2 pin COPs. The crank and cam sensors all share the same 2 pin connector that is similar but different to the 4cyl

dratec items i found.

The sensors are stamped with the Ford logo so it shouldnt be that hard surely!

I have the whole thing jury rigged with some miniature spade terminals for now.

On another note, although the engine fires it always conks out after 30-90 seconds

Is there anything weird i should look out for, perhaps the presently disconnected VVT, or IMT setup?

mgb281 - 21/11/24 at 06:58 AM

Text I have been very slowly progressed with fitting a AJV6 into a MGB but now that I have retired the progress is a little quicker, I

media blasted the bodyshell in September and have now epoxy primed the whole of it and base coated and clear coated the interior and underneath. Due

to the cold weather I am now looking at starting the wiring of both the whole car and the engine.

I found the ME442 on the piston heads forum where a Rocketeer owner had replaced it with an MBE ECU, Rocketeer had a big fallout with ME over the ECU

installation and offered a low cost upgrade to the MBE. Before I purchased it I spoke to the Rocketeer owner, ME and one of their preferred rolling

road tuners. ME said the poor running of the AJV6 with the ME442 was down to the lack of sensors to control the engine properly, ie no O2 sensor to

provide closed loop running, Rocketeer wanted a vey simple loom. The Dyno tuner said that he had seen the early Rocketeer inlet manifold and thought

that the whole poor running, cold start etc was down to the idle valve pipe being too small to flow enough air to give a stable idle and cold start.

The Rocketeer owner confirmed that the idle valve pipes had been replaced with bigger ones, he also confirmed that the MBE also took a long time and

several visits to Basset Down before it was acceptable. Although none of the above applies to you there must be something wrong with the installation,

is the DBW controlling the idle or is that causing the rough running? Is that possibly caused by a faulty temperature sensor not allowing the ECU to

adjust fuelling as the engine warms up?

Finally I did some searching several years ago about fitting a Megasquirt ECU and at the time Extra EFI seemed to be more geared up to supply a three

coil pack wasted spark ignition system. After further searching I found that a lot of S Type owners have poor running problems that are difficult to

cure, it appears to occur when the ignition plugs are changed, some owners had changed all the COPS to cure the problem. Even the Jaguar ECU fault

codes didn't point to where the problem lay. This is why I am considering getting rid of the COPS.

spegru - 21/11/24 at 09:04 AM

Thankyou so much MBE281, There is a huge amount in that response.

I chose ME because someone I semi know has anAJ30 running with one of theirs in a Healey replica. Unfortunately he's been useless with any

assistance though.

Although I knew of the Rocketeer MX5 AJ30 conversions I didn't know ME connection until recently.

All that back history probably explains a comment from them that they 'used to do a wiring kit' for the AJ30.....

The Rocketeer Inlet plenum does look very pretty in carbon etc but it looks very simple vs the Jaguar setup that I am using - and very expensive

I am running a wideband sensor that I would have thought should do a fairly good job sensor wise, along with Inlet Air Temp and MAP.

I am going DBW as that's what the engine had on it, although I could not use the actual '99 vintage item so I'm using a modern Bosch

73mm Throttle Body unit that ME recommended. Idle air control should not be an issue as that's all under ME360 control via that. Mechanical

throttle response seems good although one of the current symptoms is inability to rev (it stalls instead). I dont think DBW is at fault as at least

there is some reaction from the driver's seat for that.

I can see that we have alot more hat we could discuss. A pity that you are 100+ miles away. I shall try to send you a U2U and perhaps speak on the

phone?

Regards

Steve Pegrum (aka spegru)

40inches - 21/11/24 at 10:10 AM

This seems to be getting very complicated

As a comparison, here is my initial set up:

When I started this project back in 2014 there was very little information available, so I had to make it up as I went along

So I kept it very simple.

NO idle valve

NO VVT

NO cam sensor

Ford ST220 throttle body.

And after doing a bit of research on Jag forums NO COPS, just a Ford V6 coil pack and ST220 plug leads.

The ECU came down to Megasquirt or Emerald.

I chose an MS2 Xtra because of price and VEAL, aka Auto Tune.

Using the supplied Ford Iron V6 Msq, and 1/8th throttle it started first time and ran nicely, if a little lumpy, switched veal on and left it for 30

minutes

to set the idle tune.

Then ran it for around 100mile with VEAL on.

A rolling road check had it at 242 bhp and 230 ftlbs torque with a little ignition change.

With VVT activated 172 BHP, the same as Rocketeer, but around £4000 cheaper

A big thanks to Joolz at Kits and Classics for setting it up on the rolling road.

[Edited on 21-11-24 by 40inches]

spegru - 21/11/24 at 10:44 AM

Thanks 40inches. Yes it does seem that we/I may have overcomplicated this. TBH I thought it would be easier esp considering by experience with Omex

& Zetec a few years ago

As of now, i've got Cam sensors switched off (it wont sync so that's another problem), no idle valve but I do have the early Jaguar COPs.

and chose ME360 for the reason above only. What inlet did you sse with the ST220 throttle body? The ford one? I'm just wondering if my currently

not working Jaguar IMT manifold valves have any responsibility here.

I just cant work out what is going on, Normally conks out after 20-30secs although I did get 3mins after I got my wideband sensor connected yesterday.

I do have a call scheduled with ME for later today but I'm struggling to believe there is any fundamental problem

By the way though did you ever manage to identify the crank sensor plug?!

[Edited on 21/11/24 by spegru]

40inches - 21/11/24 at 12:05 PM

Used the Ford ST200 manifold with a spacer.

Description

spegru - 21/11/24 at 01:13 PM

So here I am in the garage on a freezing cold day I just found something interesting

Just now I noticed that my fuel pressure guage which is connected right next to the fuel rail extremely unstable while running. I imagine that is

because of the injectors opening and closing but could that be anything else? I did disconnect the fuel line into a coffee jar and it certainly pumps

well: ~2litres in about 20secs.

Perhaps I did not mention clearly that as well as only lasting for a few 10s of seconds, the running is also rough if I try revving at all

So I looked at the mapping using the MEITE software and got this:

You can see where the engine has been going from the thin yellow trace

Looks like alot of leaning out going on? But why? Related to the flickering fuel pressure? If not then??

[Edited on 21/11/24 by spegru]

spegru - 21/11/24 at 07:59 PM

could the leaning out be caused just by an air leak?

mgb281 - 22/11/24 at 09:06 AM

quote:

Originally posted by spegru

So here I am in the garage on a freezing cold day I just found something interesting

Just now I noticed that my fuel pressure guage which is connected right next to the fuel rail extremely unstable while running. I imagine that is because of the injectors opening and closing but could that be anything else? I did disconnect the fuel line into a coffee jar and it certainly pumps well: ~2litres in about 20secs.

Perhaps I did not mention clearly that as well as only lasting for a few 10s of seconds, the running is also rough if I try revving at all

So I looked at the mapping using the MEITE software and got this:

You can see where the engine has been going from the thin yellow trace

Looks like alot of leaning out going on? But why? Related to the flickering fuel pressure? If not then??

[Edited on 21/11/24 by spegru]

If anyone is interested I have a ST200 inlet manifold on Ebay at the moment, also a ST220 lower manifold with the tabs already welded on and ready to be milled down to the correct height. I simply didn't have enough height or room for it on a MGB so have gone for a modified ST220 one. I haven't found a way to add photos from my phone yet, can anyone guide me.

40inches - 22/11/24 at 09:28 AM

quote:

Originally posted by spegru

could the leaning out be caused just by an air leak?

I ran an S type for 2 years while building mine, and leaks in the breather system are a common problem.

The crankcase PCV valve and hoses are a nightmare, I removed the valve from the crankcase vent and

vented to atmosphere via a small filter, linked the cam cover hoses and fed into the inlet just after the air filter.

spegru - 25/11/24 at 09:22 PM

quote:

Originally posted by spegru

could the leaning out be caused just by an air leak?

Well today I had a look for my air leak, that was actually large enough to cause a hissing noise that previously I thought was normal

First I examined my inlet gaskets

gasket and its certainly true that they dont look very good.

But then I also found this on the inlet manifold/plenum

Empty air hole

wow I thought!

I sorted that missing hole easily enough and put it back together thinking that that on its own was bound to solve the problem.

But unfortunately it's hardly made any difference, other than that the hissing noise has gone

I shall get new gaskets of course but I am surprised at that

40inches - 26/11/24 at 09:22 AM

I have a Ford ST220 plenum you can have, slightly smaller and no IMT, and a straight fit, I believe

Just want courier costs or arrange your own.

mgb281 - 26/11/24 at 10:08 AM

quote:

Originally posted by 40inches

I have a Ford ST220 plenum you can have, slightly smaller and no IMT, and a straight fit, I believe

Just want courier costs or arrange your own.

Yes it is a straight swap and is potentially reversable end to end. if using in the standard position you only need to fabricate a new support bracket or move the stud on the manifold a couple of inches. Due to the inlet fouling the heater and firewall on the MGB I cut the inlet tract off and have welded a new throttle body mount onto the opposite end. Once modified slightly smaller is the understatement of the year.

I will load a photo if someone shows me how to, or perhaps Steve will post the ones that I sent him.

[Edited on 26/11/24 by mgb281]

spegru - 26/11/24 at 12:48 PM

Thanks for that offer and for all the advice

Philip, regarding posting pictures, at the top of this page you will see a tab marked Photo Archive. If you go in there you can upload your photos

and once you have don that you can click on the uploaded photo and the system will supply a link that can be copied pasted into the forums.

You can have either a full size pic or an expandable one depending on the option chosen

Very clunky but it works

Anyway I have done that and I also found the ST200 manifold that I was getting confused by

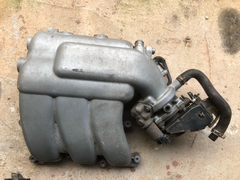

Here are the two manifolds

ST220

ST220 manifold

ST200

ST200 manifold

Unfortunately though mine is a different shape to either of these

Early AJ30 manifold

AJ30 manifold

The bulk of it is on the RH side of the engine vs LH for ST220 or both sides for the ST200. this means that I am going to have problems with all my

coolant plumbing

Meanwhile this morning I have been experimenting with the MEITE setup for the ME360 choosing various options but so far none has made any real

difference beyond the basic only running for a few seconds problem (after which it will restart and begin that same cycle again)

I am again suspecting my fuel delivery purely because of my very waggly fuel pressure guage . It doesnt do that when the guage is connected next to

the tank, only when connected next to the engine

See this vid (but ignore the part regarding the hiss from the manifold as that's now gone)

https://youtube.com/shorts/UO7k2sFVT8Y?si=rwEH4oUaC0Njyfu9

IIt may be that the pressure guage is just very poorly damped and is resonating in response to the injectors, but it does seem very odd. I did test

the flow rate by disconnecting the fuel line into a coffee jar. It filled the 2 litre jar in about 20seconds.....

spegru - 26/11/24 at 02:38 PM

While I am at it here is the manifold from an XF 3 litre, which has pretty much the same engine (although I know its got differences around the

timing chain)

This also has its bulk to the right although there does seem to be more at the front than the original S Type AJ30

XF manifold

spegru - 26/11/24 at 05:14 PM

latest video of my attempts here

https://youtu.be/2-I2feo-lw4

mgb281 - 26/11/24 at 05:22 PM

I spent this morning looking at my Jaguar engines (I have two of them and yes I know it's greedy) which was spurred by Steve's problems,

for those that don't know I am now getting closer to doing the paintwork, the engine has been in and out multiple times and three different

engine mounts have been fabricated. I initially thought that the ST200 manifold would work but it ended up too close to the bulkhead, heater and

nearside bonnet hinge so I had a rethink and after buying an X type one I decided to carve up a ST220 inlet manifold. As you can see I sliced of the

inlet tract up to the plenum and removed the raised section for both access and bonnet clearance, the closed end was cut open and a 25mm block of

aluminium was welded in after drilling a 65mm hole in the centre. I used a burr cutter to blend the aluminium block into the interior of the

plenum.

Modified ST220 inlet manifold

Modified ST220 manifold

Inlet manifold shelf

You can see that there is a shelf that runs the length of the plenum, the offside bank of cylinders is fed by the lower section and the nearside bank

by the upper section. The throttle butterfly works with one side of the flap feeding the upper shelf and the other side the lower. the shelf has been

shortened next to the throttle body by about 15mm to aid air flow. I will try and polish the upper surface of the shelf to improve airflow.

I had a good look at the engine with the S type manifold still and that open pipe feeds a small 3mm flexible hose about a metre long but I have no

idea where it went to. The rubber elbow on the PCV was good on both engines, however I think it would be easy to fabricate a rigid steel or copper one

spegru - 26/11/24 at 07:25 PM

that all looks very impressive fab work. I'm trying to avoid very much of that although I did have to get an adaptor made for the Throttle

body.

I suppose the pipe you are referring to was my mystery hissing pipe near the lower IMT valve? It's now blocked off. There was a small tube in

that area that's no longer there. It went to the electronic fuel pressure sensor. Not sure why that was there but even my fuel pressure guage has

a release tube and valve for when you disconnect or reset, so I imagine could be something like that. But I'm not using that as Ive got a

mechanical pressure regulator with a vent tube back to the tank.

Ive also got that tube to the crank case that I hear gets cracked. Mine seems to be in good condition but as of now it's not connected to

anything else anyway.

[Edited on 26/11/24 by spegru]

spegru - 29/11/24 at 06:52 PM

A bit of an update: It RUNS!

After fiddling around for ages worrying about fuel pressure, air bubbles in the fuel, fuel contamination I came across this page on the ME website

https://motorsport-electronics.co.uk/onlinehelp/html/4353.html

This led me to using the warmup table to enrich everything.

I know this is wrong but It WORKS!

Enough at least for me to be able to move on and cease worrying about fundamental issues

So in summary it seems the mixture was far too lean

Quite why that is and why MEITE did not tell me so, I do not know. A problem for another day week or even month

What a relief

Another vid is going up about this tonight

spegru - 8/12/24 at 09:40 AM

Final update on this thread I think.

Eventually I got some proper feedback from ME including a new map that does not include my temporary fix using the warmup table.

It works!

I wish I knew exactly what they did to the map but this will do for now and I can be confident that there is no underlying problem

spegru - 16/12/24 at 01:56 PM

or not final post on this thread,,,,,

Has anyone managed to get Cam Sync on the AJ30?

Ive tried every combo I can think of, and Ive used well shielded cabling - but nothing

I'm wondering if there is something different about the early AJ30 cam pattern?

thanks?

spegru.

PS and I'm still after info about the connectors on the cam/crank sensors & the 2 wire COP coils (they are all the same)

mgb281 - 16/12/24 at 07:29 PM

I can let you have 2 pin COP plugs at a later date, the Jaguar engine that I was hoping to buy is still with the seller. He has been trying to sell it

for eighteen months and canít be bothered to find a pallet!

I have no idea what you mean by cam synch but you must be getting an accurate cam signal to run the COPís or have I got that wrong? The up to 2002.5

engine has quite a few differences, up to the. The VVT was a simpleton/off switch but the later engine uses a continuously VVT. Other changes include

the inlet manifold and four pin COPS.

spegru - 4/1/25 at 04:28 PM

Happy New Year everyone.

I am pleased to say that not only is the engine running, but that I have finally identified the correct connector type for the Coil on plugs, Cam

Sensor and Crank Sensor

They are 2 Pin Furukawa plugs,

They are listed as being for Ford Focus, Mondeo & Suzuki - but they are different from the COP plugs I previously found listed for Duratec.

There are a bunch of different plugs with a similar appearance but the distinctive aspect is the assymmetric oval shape, the yellow insert and the

pins being slightly offset downward

Here is the Ebay listing , where I got a set of 5, including the mating half that

I don't really need.

In fact this is a pretty neat waterproof plug set, currently at a very reasonable price of £8.34 for a complete set of 5 for the two pin version

required

Further investigation has revealed that these Furukawa plugs also exist in other versions with up to 16 pins

[Edited on 6/1/25 by spegru]

mgb281 - 4/1/25 at 05:55 PM

Good find Steve. Have you seen this Jaguar repair manual? If not itís a useful one to add to your collection.

http://jagrepair.com/images/AutoRepairPhotos/Engine%20Repair%20Course%20Code%20168.pdf

spegru - 6/1/25 at 12:49 PM

Thanks for that Philip. I hadn't seen it.

Now downloaded......

Partofthechaos - 9/2/25 at 12:23 PM

Following on from your progress starting your engine, did you use both cam sensors or just one? I'm using an Emerald K6, I can only find one

place to assign a cam sensor, so I'm assuming one is fine?

I've asked Emerald about 17 times and not had a response. They can't manage to send me a base map either!

[Edited on 9/2/25 by Partofthechaos]

mgb281 - 9/2/25 at 12:53 PM

I am not sure if this helps but I bought an ex Rocketeer engine loom and it only had one cam sensor. Considering the ME442 could cope with two cam sensors, VVT, Wideband O2 sensor etc it makes you wonder why they used such a cut down spec. I am going to add the extra sensors.

Partofthechaos - 9/2/25 at 12:55 PM

Thank you, it does seem odd! Though it tallies with Emerald seeming to only have one place to assign a sensor, maybe one is enough. I have routed both cables and this is my last bit of wiring to complete now. Keen to get it finished!

mgb281 - 9/2/25 at 01:04 PM

I am thinking that one is sufficient to run it but two enable the OE ECU to detect a fault if one cam is not varying properly.

Partofthechaos - 9/2/25 at 01:32 PM

That makes sense, I hadn't considered VVT monitoring.

I'm planning to remove the shorter cable, so I can swap the remaining cable from one sensor to the other if needed. OK, forward we go!

spegru - 10/2/25 at 11:52 AM

good to see the forum is working again

So far I have never been able to get cam sync with the ME360.

The Jaguar wiring is set up for two cam sensors although neither of those are screened so I replaced those sections with screened stuff a few weeks

ago.

but havnt pursued that so far as Ive other things to work on, but I really want that working.

Seems to me that in order for the cams to sync, the pattern needs to be recognised, which offers the possibility that either the wiring is reversed,

so reversing the pattern, or that since my engine is an early one with only 2 VVT positions, that the pattern is actually different from the one that

the MEITE software is expecting for a (later) AJ30 with continuous VVT - which would be a real nuisance as presumably it could need different firmware

for that pattern

mgb281 - 10/2/25 at 12:51 PM

Steve, would you like to have a look at my ex Rocketeer ECU, it was set up by ME so should be configured correctly. however if you read this; https://www.pistonheads.com/gassing/topic.asp?h=0&f=47&t=1709711&i=760 you may beg to differ

spegru - 10/2/25 at 02:36 PM

Thankyou Philip. Certainly I would. I also wonder whether you have / would be able to, upload the map that you have from the ECU, and simply email it?

It's not that big @1.2MB. Of course you'd have to power up the ECU to get it if you havn't though. Did I see that yours is an ME442?

I'm not sure whether that matters though as the map seems to all text as far as I can see. Of course I can also send you my (rather sketchy) one

too

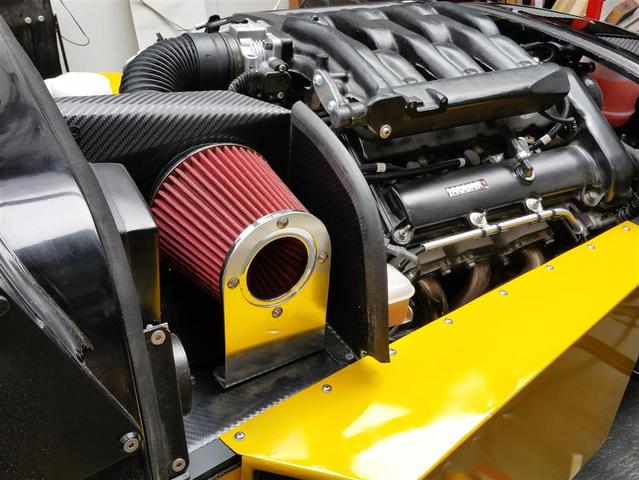

While I am here again, I thought it would be useful considering my concerns about Cam sync with regards to early/late AJ30s so I just popped over the

road to get a pic of my neighbour's 2017 Jag XF engine - just to illustrate the difference between the two versions

The first pic with the silver cam cover is mine, from a 1999 Stype - with only 2 VVT positions

1999 AJ30

The second pic with he black cam cover is from the 2017 XF - with continuously variable VVT

2017 AJ30

As you can see the cam control plug is behind the cam chain in the earlier and in front on the later one. Oil filler caps are also in slightly

different positions

And the question is do the cams both have the same sync pattern? and which on is built into the the Motorsport Electronics MEITE & ME360/442

Which version of the AJ30 have Forum members got?

spegru - 10/2/25 at 02:50 PM

I also note that the MX5 shown on the Pistonheads/Rocketeer forum by 'Lewis's Friend', that you referenced, appears to be fitted with

the earlier type of AJ30.

This may be good news regarding my concern, but i am not 100% sure what ECU setup that car actually has (had - this was 2020!)

mgb281 - 10/2/25 at 04:46 PM

Steve, I bought my ME442 from Jonathan (Lewis's Friend), you will see some reference to me in the thread. Yes it is a ME442 but I am a cynical

person, in the beginning there was the ME442 and a four cylinder ECU 221 which was a basic four cylinder. Then to produce a cheaper full spec ECU ME

removed the DBW function and lopped a couple of hundred pounds off the price, I suspect that few wanted the DBW and sales of the top priced ECU

crashed. I think that the outcome was the new range of 4, 6 and 8 cylinder ECU's and I am still cynical enough to believe they are the same but

with some injector and spark outputs disabled.

If you would like to borrow my 442 to pick it's brains then you are still welcome, it's setup for the early engine which I have. I did speak

to someone who fitted ME ECU's and had looked at a Rocketeer and he put the blame for the poor running on the Rocketeer inlet manifold. He

suggested that they were far too small a capacity coupled with a too small interconnecting pipe between the two halves that the idle valve fed.