Any Aj30 / Duratec30 rebuild resources and info pls

big_wasa - 24/10/21 at 08:08 PM

As title really.

Ive had the v6 several years so its time to do something with it and give it some love.

I am after any good info on rebuilding an Aj30 / Duratec30, specifically the valve timing.

Plans are a simple strip, check over and rebuild with new gaskets and seals.

Cheers in advance

obfripper - 25/10/21 at 12:02 PM

There's some useful pdfs here that may be of use.

http://www.super7thheaven.co.uk/components/duratec_v6/

Dave

sdh2903 - 25/10/21 at 06:16 PM

I have the jag manual aswell but the link above is prob more detailed. Bearings, seals and gaskets are much much cheaper in the states. I used rock

auto for all my rebuild bits even with postage and duty (all prepaid) much cheaper and all delivered within 4 or 5 days.

Badger_McLetcher - 27/10/21 at 07:13 AM

I looked at rebuilding mine when I spun a bearing earlier this year. It was significantly cheaper to buy a replacement second hand unit - about £150

vs £500 ish quid, or over a grand going through genuine routes.

+1 for Rock Auto, the parts are significantly cheaper over in the states - I never finished chasing that as the second hand unit popped up.

https://www.rockauto.com/

One of the unexpectedly high costs were the head bolts and studs for the bottom girdle. They're not reusable (stretch bolts), and about £12 a

pop from Jag.

One thing I didn't get to the bottom of is how suitable the parts from the Ford Duratec engines are for use on the AJ30 - those part prices tend

to be a lot cheaper.

sdh2903 - 27/10/21 at 09:58 AM

Problem with just buying another used one Is you could be buying another duffer. Genuine low miles ones are now rare and also starting to creep up in

price. Early aj30s are notorious for scored bores (I believe due to the early egr system in the donor) mine was making great power but drinking oil

for fun.

I've chucked In a used lump to use over the summer and am now rebuilding the original.

I reckon I'm going to be 1500 quid in by the time I'm finished. But it did need a rebore and oversize pistons due to the scoring and

I've gone forged rods to lift the rev limit a bit. Have also bought a new genuine timing chain kit. Head bolts are cheap from rock auto (mahle)

but agree on the lower deck bolts. I've cheated and will re-use as have many others with out issue. Some running huge power. If its just a

freshen up could be done much much cheaper. Some of the jaguar prices for simple seals and gaskets and bolts are eye-watering. I think for an

oversize piston jag wanted 400 each!

As far as I understand the bottom end is common between ford/jag. It's just the heads that are different.

big_wasa - 27/10/21 at 07:45 PM

Thanks for the info guys.

Iíve bought the jag book, Iíve had a look on 7 heaven and watched a few vids. Time to put on the big boy panties. I can do a Zetec with my eyes

shut.

I hadnít thought about girdle bolts. I am thinking head gaskets so I can do the valve stem seals and basically every other seal and gasket as they all

leak. The head bolts pissed me off. I bought a set thinking they where reasonable to find they where sold per bank and two sets where needed.

Mine being a Ford lump means they arenít as cheap or easy to find. Mine has the lowest millage Iíve seen for a Ford lump in a while at 104k.

I might do a build threadÖ.

40inches - 28/10/21 at 08:10 AM

The Jag valve stem seals are £8 each in the UK

Mike Wood - 29/10/21 at 06:28 PM

quote:

Originally posted by 40inches

The Jag valve stem seals are £8 each in the UK

Eye watering indeed. Any independent classic Jag parts suppliers here in the UK that cater for cars as recent as this? David Manners? Rimmer

Brothers?

If looking for ARP bolts there may be some suppliers here that could get them and sell a lot, perhaps those who normally stock ARP for other

engines?

I do despair with OE parts price gouging, as well as for classic cars the often lamentable quality of repo parts in particular electrical bits and

rubber components.

Cheers

Mike

[Edited on 29/10/21 by Mike Wood]

[Edited on 29/10/21 by Mike Wood]

[Edited on 29/10/21 by Mike Wood]

sdh2903 - 29/10/21 at 07:37 PM

There are plenty of suppliers, but not many aftermarket products other than the common gaskets. Britishparts.co.uk are pretty good

I got a full top end gasket set inc head gaskets, stem seals, cam cover gaskets, ex mani gaskets and loads of other bits and pieces for 75 quid from

the states. Equivalent price in uk is 260 quid.

40inches - 29/10/21 at 08:42 PM

quote:

Originally posted by Mike Wood

quote:

Originally posted by 40inches

The Jag valve stem seals are £8 each in the UK

Eye watering indeed. Any independent classic Jag parts suppliers here in the UK that cater for cars as recent as this? David Manners? Rimmer

Brothers?

If looking for ARP bolts there may be some suppliers here that could get them and sell a lot, perhaps those who normally stock ARP for other

engines?

I do despair with OE parts price gouging, as well as for classic cars the often lamentable quality of repo parts in particular electrical bits and

rubber components.

Cheers

Mike

[Edited on 29/10/21 by Mike Wood]

[Edited on 29/10/21 by Mike Wood]

[Edited on 29/10/21 by Mike Wood]

Got those prices from David Manners, almost £200 for a set.

The clutch slave for the ST220 is £35, AJ30 nearer £150

CosKev3 - 30/10/21 at 10:22 AM

As above regards RockAuto,excellent prices and very fast delivery.

Felpro gaskets look to be really good quality.

Girdle bolts can be re-used without issue,just don't try and restretch them obviously!

If anyone reads this that is thinking of supercharging/turbocharging the AJ30 the valve springs are too weak as standard, don't ask me how I

found out......

If you are thinking of charging a 3ltr V6 Duratec I would start out with a ST220 engine,Piper valve springs are available at a reasonable cost off the

shelf,£500.

AJ30 Piper springs only work with the Piper shim under bucket conversion,so £900 for the shim under bucket conversion and £600 for single springs,or

£700 for doubles

magpies - 2/11/21 at 01:38 PM

Check out https://www.pistonheads.com/gassing/topic.asp?h=0&f=11&t=1636478

terry's tale - he had an internal problem with his AJ30 on a rolling road and had to have a bottom end rebuild - purchased bottom end bolts from

the USA as MUCH cheaper.

sdh2903 - 6/11/21 at 12:02 PM

Now that my heads are back with a clean bill of health and have all the parts (apart from some lifter shims perhaps) to stick it back together, have a

total a little over my estimate

Block rebore and hone. 250

Crank polish. 60

New pistons and rings. 130

Top end gasket set + seals 89

Bottom end gasket set. 36

Head bolts x 2 sets. 33

Main bearings 24

Conrod bearings 19

Couple of spare oil filters. 8

Headwork 144

New rods 545

Timing chain kit 360

Total 1698

My timing chain was pretty noisy hence the change, however think that was down to a guide rub strip that had a broken clip. There was no measurable

chain elongation and all the signs point to this engine having covered a lot of miles.

So without the timing chain and upgraded rods you could refresh one of these pretty cheaply despite there being a lot of stuff out there saying they

are too expensive to rebuild. You just need to shop around.

[Edited on 6/11/21 by sdh2903]

andygtt - 25/11/21 at 02:11 PM

There are a lot of good new parts around for the AJ30 engine, you just need to keep you eyes open... just last week i sold a pair of brand new

complete heads along with new chains new forged rods, new pistons and rings etc etc along with a second hand block and crank (complete engine

basically mostly new) for just over £1k.

There is also an online Jag parts web site were you can get bearings, rings etc etc MUCH cheaper than if you buy through ford (even tho they are the

same).

I bought ARP hardware for the heads and block bolts as it means you spend once and has saved me significant money over the years... the Ford arp head

bolts fit the Jag heads but you do need slightly different block bolts so you can bolt the windage tray which is different to the ford.

if you want cams etc go with the ford heads, its thousands cheaper for the ford and extra revs for the Jag can only be used if you replace the stock

oil pump. (I took the ford heads to 8000rpm and the oil pump is marginal at those revs so is the limiting factor).

andygtt - 25/11/21 at 02:17 PM

quote:

Originally posted by Badger_McLetcher

One thing I didn't get to the bottom of is how suitable the parts from the Ford Duratec engines are for use on the AJ30 - those part prices tend

to be a lot cheaper.

Bottom end of the AJ30 is identical to the Ford ST220.. same block, crank, rods, pistons, oil pump... there are difference is the core plugs and the

head gaskets are not interchangeable (but the jag ones are way cheaper I've found).

MootchA - 18/12/21 at 09:28 PM

Andy,

Do you know if the ford Con rod bolts fit the jag rods

andygtt - 19/12/21 at 09:44 PM

Yes as they are the same rod, I have spare brand new Ford/jag rods with bolts if you in need of them.

MootchA - 21/12/21 at 04:43 PM

Andy,

Thanks for the offer, but I only need bolts at the moment, I might go single turbo in the future, I will then take kevs advice and go steel rods

and arp bolts, my only concern going the turbo route would be a mandatory 32mm restrictor.

andygtt - 21/12/21 at 05:45 PM

No Worries, i have piles or stuff left over from the engines I've stripped.

I wouldn't recommend going charged with stock rods (even with apr bolts) and without machining oil squirters into the block (please don't

copy the guys guide online as there are some significant mistakes and incorrect assumptions/statements).

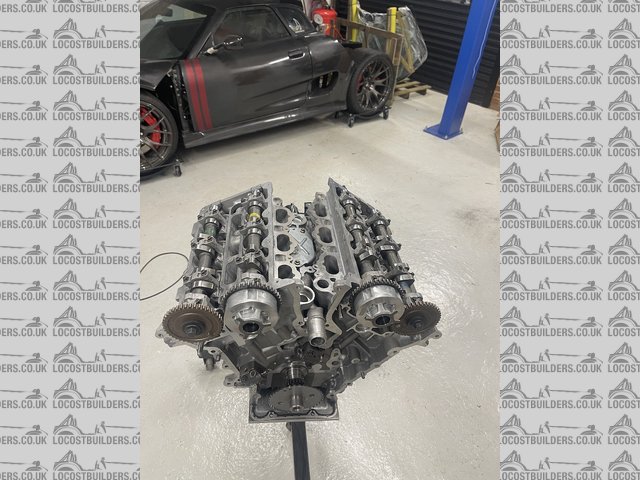

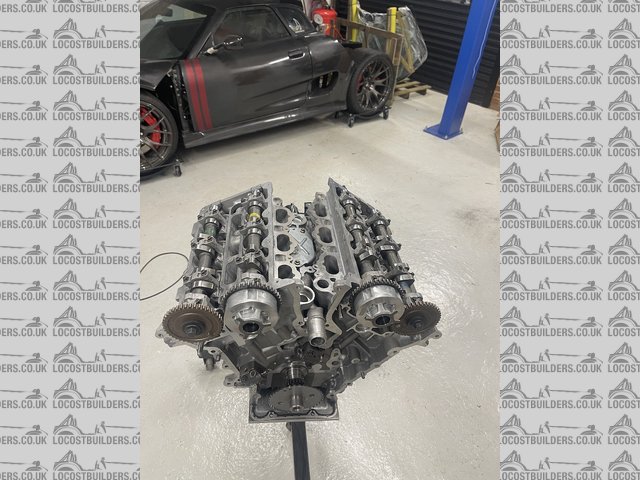

I moved from the ford heads to Jag heads and its cost me a bloody fortune, hopefully it will be worth it..... Ive actually been finalising the engine

build over the last few weeks, fitted the heads and measured & made all the shims... taken bloody ages, i can now see why 'blueprinted'

engines cost so much more.

Description

Description

Description

Description

Description

Description

CosKev3 - 21/12/21 at 05:52 PM

quote:

Originally posted by andygtt

(please don't copy the guys guide online as there are some significant mistakes and incorrect assumptions/statements).

Which one?

A link would help please

andygtt - 21/12/21 at 06:12 PM

Chamber of Knowledge or something similar.... the guy has done a really good build up diary of him doing a rebuild on the AJ30 and then boosting it,

he just got caught up in some information he found online about the noble oil squirters that was totally incorrect and based his assumptions and

design off of that information. (noble ones have a 4mm hole with a brass insert restrictor deep inside the hole).

His squirters are also pointing directly up and thus at the wrong place on the piston, something that's pretty critical to cooling them

effectively.

Other stuff about the engine on his site is really good, its a great write up with a lot of hard to find information... its just i had a couple of

people mention to me they planned to copy his method of oil squirter design (BTW I also did my own, but I had 2 already machined blocks on the bench

to look at and analyse to help).

andygtt - 21/12/21 at 06:18 PM

found the site.... lot of very good information in here.

https://www.chamberofunderstanding.co.uk/tag/aj30/

Worth mentioning, there are actually a number of different thicknesses of head gaskets for the AJ30, i found one that had a 1mm spacer ring to reduce

the CR slightly (I didn't use it as i had low CR pistons)... also there are a few variations on the heads, the later ZF Jag have fully variable

inlet timing rather than on off switch like the S-type... I've bought one of these later crate engine from Jag and am going to see if i can spool

the turbo with the VVT.

CosKev3 - 21/12/21 at 08:35 PM

quote:

Originally posted by andygtt

, he just got caught up in some information he found online about the noble oil squirters that was totally incorrect and based his assumptions and

design off of that information. (noble ones have a 4mm hole with a brass insert restrictor deep inside the hole).

His squirters are also pointing directly up and thus at the wrong place on the piston, something that's pretty critical to cooling them

effectively.

.

Better than none at all though?

So are you saying Noble don't just drill straight through the block the same as he has from behind the main bearings?

Will lubricate the gudgeon pins better than just the splash you rely on as standard.

Also he's not going for anywhere near the power you run,so temps will ne nowhere near yours.

andygtt - 22/12/21 at 09:06 AM

I do agree about power targets we have very different goals, Im going for big power and high rpm so I have stressed about the details.

Yes Noble do drill through the main bearings, but it is done at an angle to point to the crown not the pin holder in the piston so it acts within the

piston and bore completely differently. They also absolutely all use a bronze insert within the hole, even with these inserts oil pressure isn't

great on idle (I also think the noble ones might be smaller than the ones he has used, but i have not checked that).

If they are straight up at the edge (as his are) they simply spray on the Pin holder part of the piston and don't get to the crown so

significantly less cooling (the reason for doing it). Also the piston comes down and practically kisses the part of the block they spray from, so

fitting them from the piston side means the piston almost touches them (I was worried they would actually touch but he must have checked that).

More Oil will go on the bore rather than inside the piston, meaning the rings might not be able to clear it, plus the oil will be spraying within a

few mm of the piston directly opposing its direction of travel... I have no experience of the implications of that (also never seen it) but it might

cause the piston to rock or wear strangely or worst put a vibration into the pistons/engine, i guess the effect will be directly dependant as to how

close the pistons actually get to the squirter.

Below is a picture of the forged pistons for the engine, his (and my new ones) are similar to the ones on the left which are the cosworth ones that

came out my old engine..... his squirters will be spraying the centre of the flat underside section of the piston, and at BDC it will be a few mm

clearance max.

Description

Also IMO the insert is best to screwed into the bearing side not the piston side and be at an angle to actually spray the crown.. gives more clearance

to the piston and means it can't come out within the bore... I used a non return insert that only sprays above 30psi, the stock noble ones are

just a small hole (around 0.6mm I think) so spray all the time.

The solution is simply to drill them at an angle so they point at the crown which is what all squirters i have seen do, I used a scrap block and

drilled each one differently and then selected the version that worked best.

MootchA - 22/12/21 at 12:15 PM

andy,

i know you are dry sumped, but, is a standard noble sump baffled in any way, or is the sump similar to a jag/ford sump which is pretty open really. i

have found a pic of a nice baffled sump of a noble forum, but not sure if this is standard. i would put the pic up but i cant find the url.

andygtt - 22/12/21 at 01:13 PM

the first nobles ran the standard ford ST200/ST220 sump... but there were failures especially on track and the factory came out with an upgrade called

the 'Track day sump' lol

Most nobles now run the TDS, as did I, but when i fitted the motel ECU it because clear to me and another friend (who had the same ecu) that there was

an issue in a specific type of long sweeping corner where oil pressure dropped a little under throttle so my friend developed a bolt in trap door

arrangement that solved the issue completely.

The noble TDS holds just under 10 litres of oil and is just a modified ST220 ford sump with extra sheet metal welded to make it big wing... the new

trap doors are litteraly 4 hinged rectangles around the pickup (which is extended around 1inch longer) to reach the bottom of the larger sump.

MootchA - 22/12/21 at 02:03 PM

Ahh OK, I have seen the tds, strange looking affair, 10 litres is a hell of an additional amount, I will try and modify my existing sump to suit my

proposed application, rallying, no different from track day really, new tig for Xmas I think !!, the noble forums are a mine of information.

sdh2903 - 22/12/21 at 04:18 PM

quote:

Originally posted by andygtt

There are a lot of good new parts around for the AJ30 engine, you just need to keep you eyes open... just last week i sold a pair of brand new

complete heads along with new chains new forged rods, new pistons and rings etc etc along with a second hand block and crank (complete engine

basically mostly new) for just over £1k.

Bloody hell I wish I'd seen that lot for sale before rebuilding mine

RWD Focus - 22/12/21 at 08:50 PM

I went to a dry sump set up on mine after issues with getting sumps to clear my crossmember and also concerns about oil surge etc. Mines also in a

rally car

Oddified - 22/12/21 at 09:30 PM

On mine, i used the standard size st220 sump and made some gated baffles around pick up to stop surge (my engine is longitudinal unlike the Noble

though so probably a bit less likely to have an issue).

As for oil jets, i used bmw valved jets which don't open below around 25 - 30psi and they're drilled/fitted at an angle. I didn't like

the idea of a simple hole/oil bleed like the Noble used. I've seen people use mig welding tips as jets, but it's still just an oil pressure

leak at idle.

MootchA - 22/12/21 at 10:56 PM

Ian,

Any chance of a picture of your gated sections

Oddified - 24/12/21 at 09:27 PM

quote:

Originally posted by MootchA

Ian,

Any chance of a picture of your gated sections

I didn't take any pictures sorry, but basically it was a box with hinged flaps around the pickup, welded underneath the tin splash plate screwed

into the sump.

andygtt - 29/12/21 at 12:45 PM

quote:

Originally posted by Oddified

quote:

Originally posted by MootchA

Ian,

Any chance of a picture of your gated sections

I didn't take any pictures sorry, but basically it was a box with hinged flaps around the pickup, welded underneath the tin splash plate screwed

into the sump.

Which is exactly what the noble one is like

MootchA - 29/12/21 at 02:03 PM

I have found a firm called g15 engineering, they make baffled gated sumps for cossies etc, I have been in touch with them but they won't sell me

the lower gated box separately, so I will buy an rs 2000 one and modify it to fit, they look good quality so might be of interest to someone else.