Continuing saga of the Supercharged Zetec

ChrisL - 22/7/19 at 01:59 PM

The project that just keeps giving's latest instalment .

I've had the car running fine without the SC and smaller injectors, so some good progress. With a decreasing amount of time before a planned road

trip and the SC squealing I decided to opt for plan B, that went well part from a dodgy clutch, but that's another story.

Back to the squealing, the SC i was using was in a right state when I received it, I love how people on the bay can advertise something as 'fully

working' and when it turns up it's seized. After replacing the needle bearing with no improvement I decided it must be the rotor bearings

that have had it. These are replaceable but the tolerances on getting the rotors and gears lined up were a bit (way way too tight) for me so I

purchased another SC that looked to be in a nearly new condition, PTFE still intact on the rotors.

Dropping in the new SC and it's no better. In fact it's so bad that the tips of there belt's vees are being pulled off. At one point I

thought I'd solved it but alas I'd blown a hose off.

I've put a couple of videos below which show it running at idle and with a tiny amount of throttle (squealing).

I'm pretty sure the belt is as tight as it can go. My first attempt at running the SC had the belt flying off, so I aligned everything with the

engine out and am reasonably happy that I don't have a belt alignment issue. My thinking, which could easily be way off, is that either I've

got another knackered SC or the alignment of the pulley on the rotor shaft is wrong. I can't use the original pulley (100mm) as it has a

different position due to it being clutched.

Description

Description

Description

https://youtu.be/VXGugMx-wBo

https://youtu.be/KSBDgRjFV0Q

bi22le - 22/7/19 at 10:29 PM

So there are no blockages in the induction system at all?

Im a keyboard warrior with SC (I have read a lot and have one in my garage, but have actual experience), it sounds like its struggling to push the

air, out. This would ring true with a hose popping of and it suddenly sounding ok.

se7ensport - 22/7/19 at 10:31 PM

That second video sounds like the belt is being shredded.

Itís got to be out of alignment in one of the 3 axis. Iíd use a digital spirit level (thereís an app for that) and check that it is square to the

crank pulley both horizontally and vertically, if the angles match then check that the first v aligns between the SC and the crank, use something like

glass that wonít/canít flex and measure the angle off that. Could also use a dial gauge.

If they all align statically then the SC mounts are likely to be flexing under load; this would also explain why at tick over if sounds alright, but

as the revs rise it starts to eat the belt.

Good luck.

se7ensport - 22/7/19 at 10:34 PM

Is it single or twin throttle set up?

mark chandler - 23/7/19 at 07:02 AM

When you spin the charger air has to go somewhere or it will be really hard to turn and eventually self destruct..

Lock the secondary throttle bodies wide open, the ones on the head allowing the air to pass through the engine then start, see what happens, it should

drive fine just be a little laggy.

If it's quiet as above the bypass cannot be working correctly, It will just use a lot more fuel so sure on idle the bypass is wide open so the

air just goes around inside the charger.

Whereabouts do you live, maybe a second pair of eyes required?

[Edited on 23/7/19 by mark chandler]

ChrisL - 23/7/19 at 08:11 AM

It's a single throttle setup at the moment, with the throttle between the charge cooler and the plenum.

When I set it up I used a straight edge between the crank and the SC pulley, but admittedly didn't check X and Y, so will check that. One thing

that I also need to check is that there are definitely no blockages. When I was putting it al together I was in the habit of stuffing kitchen roll

down open tubes, to stop debris falling in, just wondering if one of them got using in too far to see and I've forgotten it!!

I'm in Henlow, Beds if anyone fancies a look (once I've checked the above)...

Thanks for the advice, all good stuff :-)

number-1 - 23/7/19 at 07:37 PM

Hi mate. I must say before i give my opinion, that do not know what im talking about....just giving an opinion based on what ive found out over the

last 2 months re supercharged zetecs and trying to sort mine out.

The 2nd video where after you rev and the car looks like its about to stall.....to me indicates there is too much of a build up of back pressure when

you come off throttle and it backs up into the SC causing it to almost stall. (I will try and find where i read that).

From what ive researched.....

1 TB is used when no intercooler/charge cooler is used and normally goes before the SC

2 TB's when a charge/intercooler is used and the 1st is before the SC and second is before the air intake plenum

Hope you manage to sort it mate.

number-1 - 23/7/19 at 07:40 PM

post number 5. With the 2 TB's it limits the amount of air allowed into the SC and prevents the back up

http://www.turbosport.co.uk/showthread.php?t=100242

ChrisL - 24/7/19 at 09:17 AM

I've been wondering the same thing, but a couple of things that I think mean that the squealing isn't caused by not having a second TB:

1. The belt starts squealing with a tiny amount of throttle, so very low or no boost;

2. I have a blow off valve between the SC outlet and inlet.

I could still have issues that require a second TB and I know that Red7, whom I'm plagiarising, uses 2 TB so I imagine I'll end up with 2.

mark chandler - 24/7/19 at 08:26 PM

"It's a single throttle setup at the moment, with the throttle between the charge cooler and the plenum"

That's your problem, it's always boosting into a closed throttle butterfly.

It needs to be

Intake <> butterfly<> vacuum take off for bypass<> bypass<> supercharger<>bypass<> intercooler <> engine

Idle = low pressure holding the bypass open, air circulates charger outlet to inlet engine runs on air leaked past the butterfly or idle valve.

WOT = atmosphere, bypass closed, air now goes through the charger to the engine (boosted)

Kind regards

Mark

[Edited on 24/7/19 by mark chandler]

ChrisL - 25/7/19 at 01:48 PM

OK convinced, TB on order, will update once it's fitted.

Cheers

Chris

mark chandler - 27/7/19 at 07:39 AM

Once you have mounted the new TB in front of the supercharger lock the existing one open and it it running sensibly, after this you can bring the

intermediate throttle body back into play, it needs to open before the new (primary) throttle body.

Cheers

Mark

number-1 - 27/7/19 at 08:16 PM

Not sure if this helps.....but on my set up i have a separate 6pk belt running from the SC to the drive pulley and a separate belt for the rest. I can

try and get a picture tomorrow.

OP i have u2u you

ChrisL - 1/8/19 at 08:00 PM

I've added the second TB. Currently playing with getting a reasonable idle atm, will post an update once I've made some progress (or not!!)

ChrisL - 29/9/19 at 01:55 PM

Progress!

It looks the belt squealing was caused by not having the blow off valve actuator pipe connected. I've removed the second TB and been out trying

to sort the tune

So many thanks to all that offered their advice!

Unfortunately my run was cut short by copious amounts of smoke. My bodged oil breather pipe turned into an oil spray gun, and attempts at fixing it

didn't really help, but I did at least make it home. I've blanked off the exhaust side breather but I'm a bit concerned about how much

oil came out. It's dropped about 3mm on the dipstick. Should I be getting this amount of oil out? Or i this a sign of something being wrong?

number-1 - 30/9/19 at 01:12 AM

Glad to hear its almost sorted. Did you stay with the TB between the charge cooler and intake plenum?

ChrisL - 30/9/19 at 08:53 AM

Yes the TB is after the charge cooler and before the plenum.

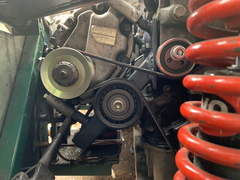

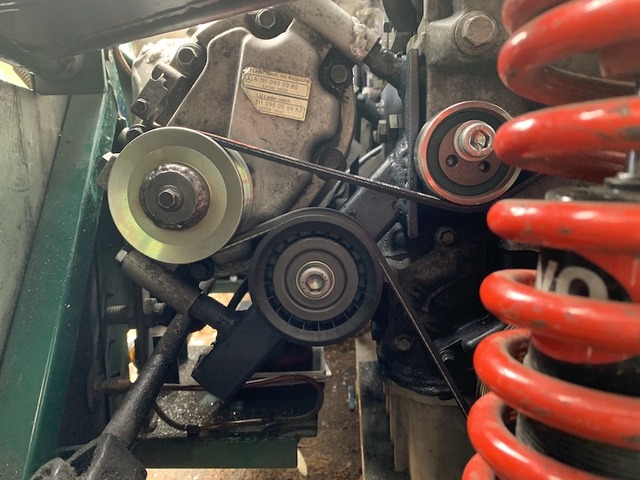

cr500dom - 20/1/20 at 11:14 AM

Hi, What alternator kit are you running on that ?

Been looking for a nice solution to a low LHS mount for a while now

Cheers

Dom

ChrisL - 20/1/20 at 05:53 PM

It's a Denso alternator with a homemade mount. It hangs off the idler pulley with a pair or bars that hold the top mount then some box section

and a plate bottled to the sump for the bottom mount.

jeffw - 20/1/20 at 07:40 PM

quote:

Originally posted by ChrisL

Unfortunately my run was cut short by copious amounts of smoke. My bodged oil breather pipe turned into an oil spray gun, and attempts at fixing it

didn't really help, but I did at least make it home. I've blanked off the exhaust side breather but I'm a bit concerned about how much

oil came out. It's dropped about 3mm on the dipstick. Should I be getting this amount of oil out? Or i this a sign of something being wrong?

Don't blank of the crankcase breather, you'll pressurise the crankcase and blow the dipstick out. Use the blacktop crankcase breather with

the valve remove and run it into a baffled breather tank. Do the same thing with the cam cover. I ran a spring with a clip to hold in the dip stick

as well.

ChrisL - 21/1/20 at 09:46 AM

Thanks for the info Jeff. I've run a compression test and am seeing very low readings. I'm pretty sure that this went wrong due to as failed

coolant pipe that lead to the engine getting up to 114 degrees which is enough to warp the head. I have a replacement engine and plan on doing what

you've said re the crankcase breather, and replacing the coolant pipes!!