Sierra Clutch problem with xflow 4 speed

Blairm - 19/1/05 at 07:21 PM

Hi,

I orignally was going to use a Type 9 5 speed box on a crossflow and had the flywheel set up with the larger sierra clutch. Eventually I had to go

back to the 4 speed because the chasis did not clear the type 9 and went about grinding the bell housing to clear the clutch.

All fits well but the clutch pedal pressure is quiet high. I am guessing the geometry is different on the type 9 fork than the 4 speed (no longer

have a type 9 to compare) and this may be the problem.

Does any one have any ideas? I thought about extending the arm on the bottom of the pedal that goes through the floor that the clutch cable connects

to to give me more mechanical advantage, but this would protrude along way through the floor and possible get caught on objects.

Cheers Blair

[Edited on 19/1/05 by Blairm]

britishtrident - 19/1/05 at 08:32 PM

I am a bit puzzled as to why you changed the clutch for the bigger heavier Sierra type as it is quite easy to mate an xflo to a Sierra box using a

Sierra 1300 clutch which is the same size as Xflo . Another way to do it is use a Hillman Avenger driven plate.

As to your current problem a couple of things spring to mind first check that at the pedal end the cable is correctly aligned with the quadrant ---

if the inner cable isn't aligned truly tangent to the quadrant the pedal action will be very stiff indeed.

The clutch pedal will also be very stiff if the cable routed in tight bend.

The other to check is that the release fork is properly engaged on its pivot and that the release bearing is the correct one and properly fitted. If

this is OK the the fork should sit at a sensible angle

From your description I don't understand you pedal arangment --- are the the pedals pivoted at he floor organ style ? if that is the case

extending the bit that the cable attaches to will REDUCE the mechanical advantage.

If all else fails fit a hydraulic clutch using a SAAB slave cylinder.

[Edited on 19/1/05 by britishtrident]

[Edited on 19/1/05 by britishtrident]

alfasudsprint - 19/1/05 at 11:43 PM

changing the pedal ratio will help, or extend the release fork to give greater leverage, this will of course extend pedal travel, which you may or may

not want.

Tim

Blairm - 20/1/05 at 12:45 AM

Thanks guys,

British Trident the saga of the bigger clutch was on the advice of the engine builder. He said to use the bigger plate as it was better suited to the

power of the crossflow which is well worked (but at the end of the day will not be that high

Yes you are correct when I think about it if I extend the pedal below the flow it will be worse.

What is involved in the Saab hydraulic conversion?

Cheers Blair

[Edited on 20/1/05 by Blairm]

britishtrident - 20/1/05 at 03:01 PM

I have been thinking youre problem over it could be something to do with Sierra pressure plates having curly ends on the diaphragm fingers while the

Escort release bearing is designed for a diaphragm with flat fingers.

Blairm - 20/1/05 at 07:12 PM

Hi British Trident,

To be honest it was so long ago I bolted the box on I can not even remember what thrust bearing I used. It was new, and I think it was the sierra

unit. From memory it clipped into the fork with no problems though.

Can anyone tell me if the Escort/Sierra thrust bearing mount on the fork the same?

The cable is fairly tightly bent. May need to get another longer unit made to see if that helps. It also does not line up perfectly to the pedal

adding more friction. I may put a picture up tonight NZ time to see what you think of the cable arrangement.

Thanks again for your help

Cheers Blair

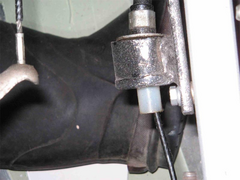

Blairm - 21/1/05 at 05:46 PM

here is a picture of the cable. I think I can improve the alignment to the pedal but this reduces the radius of the bend from the fork. Maybe a much

longer cable?

Comments please

Rescued attachment clutch cable 1.jpg

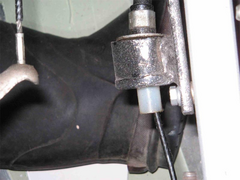

Blairm - 21/1/05 at 05:50 PM

And the cable radius

Rescued attachment clutch cable 2.jpg

flak monkey - 21/1/05 at 05:51 PM

This is a bit better size....

David

Rescued attachment clutch.jpg

Blairm - 21/1/05 at 05:55 PM

Sorry guys, yes this was my first ever picture attachment and now I no to cut them down.

Baldrick - 21/1/05 at 06:05 PM

Cable radius looks no worse than mine. My pedal action is smooth & light (well, I've never had any complaints )

)

)

)