hth

I think the only real answer will be go hydraulic, but here goes:

Type 9 gearbox, Haynes roadster as book foot pedals, I use the standard clutch cable pulled by the pedal, the cable then goes forward along the side

of the engine approx 18 inches to 2 feet and then hairpins back to the lever on the side of the type 9. Because it is a relatively sharp 180 bend

the pedal is stiff to move, but actuates fine.

I was wondering about a short cable to a bracket on the engine mount. Then a simple lever and solid rod, or cable inner back to the clutch lever,

removing the 180 degree bend in the cable but not sure on space or where to get cables made.

The issue is I do not wish to have to remove and split engine and gearbox during driving time.

Any ideas or other that have already solved this issue.

Adrian

[Edited on 11-7-18 by AdrianH]

I have a pulley on mine, very simple, light clutch and no additional cable wear,.

hth

A pulley as in a wheel style thing?

With the pulley where is it mounted and would I assume just an inner cable no outer, how do you allow for movement between chassis and engine box, I

appreciate there is not much movement.

Any pics?

Adrian

almost no movement between engine and chassis, and although this is a great picture of accident damage, the aluminium pulley can be seen in the

background

NSF- took most impact

I'll look for a better one

I used a 2:1 ratio lever for the throttle cable on the bike engine. A beefier version should be ok for a clutch?

Description

quote:

Originally posted by HowardB

almost no movement between engine and chassis, and although this is a great picture of accident damage, the aluminium pulley can be seen in the background

NSF- took most impact

I'll look for a better one

My car has a type nine using a cable operated clutch with no problems with pedal pressure , what engine and clutch are you using?

Can you not fit a longer cable so there is a gentler bend in it?

The engine is a 1.8 CVH and clutch , gearbox etc are all standard.

If I remove the cable clean out and lightly lube it is fine for a while and then gets stiffer, also I am starting to have ankle issues so it would be

a great help to make it easier.

As it is the cable goes forward of the engine mount and then 180 back and the bends is probably a radio of 2.5 inches that it forms naturally, so I

think I end up with steel on steel on the inside I tend to think it has worn through the nylon sheath.

So keeping the cable short and trying a lever or similar system where I can can adjust the pivot point could help me a lot.

Adrian

[Edited on 11-7-18 by AdrianH]

If lubricating the cable helps for a while I would suspect the cable has worn the outer casing , a new cable is about a tenner . If you want to try a different length Burtonpowers catalogue used to list details.

Thanks

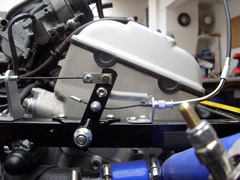

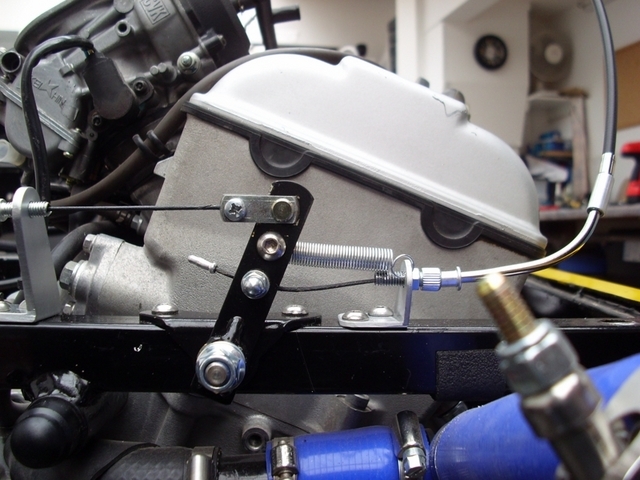

Just thought I would revisit this thread as I have been working on an assembly of sorts:

Clutch lever 1

Clutch lever 2

Looking at the picture the part in the vice will fit into the hole for the clutch cable, the smaller hole at the bottom is for a 10mm hole in the

bottom of the gearbox housing that gets used by the filler plate.

The lever has around 35mm travel, so I think that will be enough.

The thing I need to fathom is what tool and ferrules do I need to crimp to the clutch cable has anyone done that type of thing?

Adrian

The AA carry screw on type fittings to make up cables but no idea where you get them from.

Seems a clever but complicated way of avoiding using a longer cable with a bigger rad though.

Although not ideal, Could you not fit the fixed end of the sheath to the clutch lever and the actuating end to the fixed point on the chassis or block

or transmission casing?

Canīt upload photo.

If you send me your e mail, I can send Technical (Very technical) drawing.

[Edited on 7/25/2018 by Angel Acevedo]

quote:

Originally posted by Dingz

Snip..

Seems a clever but complicated way of avoiding using a longer cable with a bigger rad though.

Surely it would have been an excellent time to convert to a lovely hydraulic clutch  You can get slave cylinders for "pull" operation.

You can get slave cylinders for "pull" operation.

quote:

Originally posted by MikeRJ

Surely it would have been an excellent time to convert to a lovely hydraulic clutchYou can get slave cylinders for "pull" operation.

that looks a neat solution, my awful picture essentially shows a pulley that does what you have done with levers,. I imagine that both give similar

advantages when trying to package the clutch cable in a small space, after lightness comes reliability

quote:

Originally posted by HowardB

that looks a neat solution, my awful picture essentially shows a pulley that does what you have done with levers Snip..

quote:

Originally posted by AdrianH

Anyway we each have our own way to crack a nut. When I removed the cable from the car it had over the years formed itself in to the shape some of the plastc was going semi hard holding the shape and that included the inner, I also got crap out of the cabnle when I cut it in half so that would not have helped.

[Edited on 25-7-18 by AdrianH]