Originally posted by Sam_68

quote:

Originally posted by james h

Both heads are off...

quote:

Originally posted by james h

I'm thinking valves ...

I'm confused...

As above!

I've taken the heads off the V8 in my '98 LS400, to diagnose a knocking/tapping sound (suspected bent valve due to hydrolocking from a

heavily leaking injector).

Both heads are off - I'd have thought the crank would turn consistently and freely - but no!

As cylinders 1 & 6 reach TDC (at the same time), it becomes very stiff to turn over. Is this normal for a V8?

Cheers!

James

Seems weird to bend a valve in that way did it lock solid? May of bent a rod.

Gary

Not familiar with this particular engine, is there a balancer or anything else driven from the crank that might affect rotation?

On a side note never heard of a valve bending due to hydraulicing, far more likely to bend a rod, have you checked that all pistons are coming up to

the same height? also look for unusual marks on the bore.

Cheers

Davie

Just the harmonic balancer on the front, the belt is off. It's an auto, something in the transmission maybe?

My first job tomorrow in daylight is to check properly the bores and piston heights - a quick inspection shows it to be ok.

I'm thinking valves because the compression is about half what it should be on the cylinder which had the leaky injector (the compression test

wasn't done by me mind). Surely a slightly bent rod wouldn't cause such a massive drop in compression? Though I'm willing to be

educated on this topic!

could be a bent rod, see if there is any height difference when pistons are at tdc

Rods bend on these post 94 engines , Iíve done one on my turbo 1uz bending it until the underside of the piston hit the crank web

If the injector was leaking to the point the cylinder suffered from a hydraulic lock it will more likely to have suffered bore wash than bend a valve. Bore wash will cause wear to Pistons, rings and bore causing lost compression .Quick test for bent valve is to lay the head flat with both suspect valves closed and fill the chamber with liquid( degreaser, petrol etc) then check the ports for signs of leakage.

I bent the rod until the piston hit the crank and it was only a couple of mm down in the bore at tdc

As above, Bent Rod ?

Saw this on a Subaru Imprezza once

quote:

Originally posted by james h

Both heads are off...

quote:

Originally posted by james h

I'm thinking valves ...

It still could be something to do with the transmission?

quote:

Originally posted by rusty nuts

If the injector was leaking to the point the cylinder suffered from a hydraulic lock it will more likely to have suffered bore wash than bend a valve. Bore wash will cause wear to Pistons, rings and bore causing lost compression .Quick test for bent valve is to lay the head flat with both suspect valves closed and fill the chamber with liquid( degreaser, petrol etc) then check the ports for signs of leakage.

quote:

Originally posted by Sam_68

quote:

Originally posted by james h

Both heads are off...

quote:

Originally posted by james h

I'm thinking valves ...

I'm confused...

And the winner is.... Froggy!

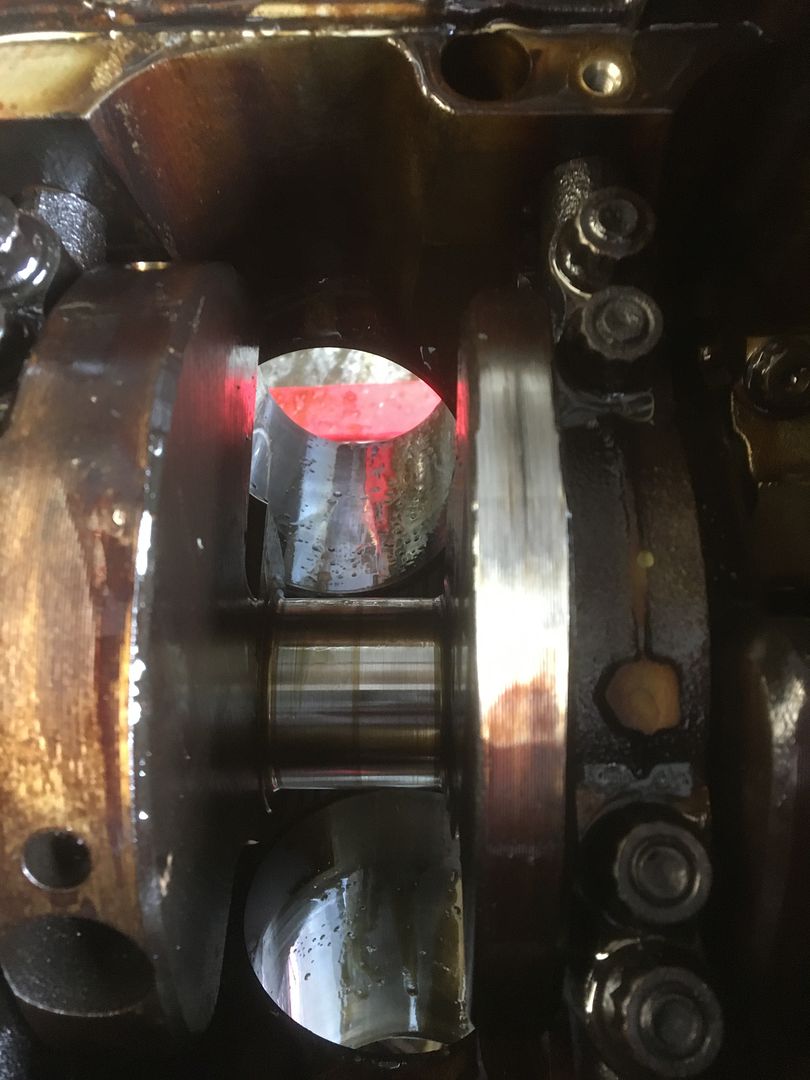

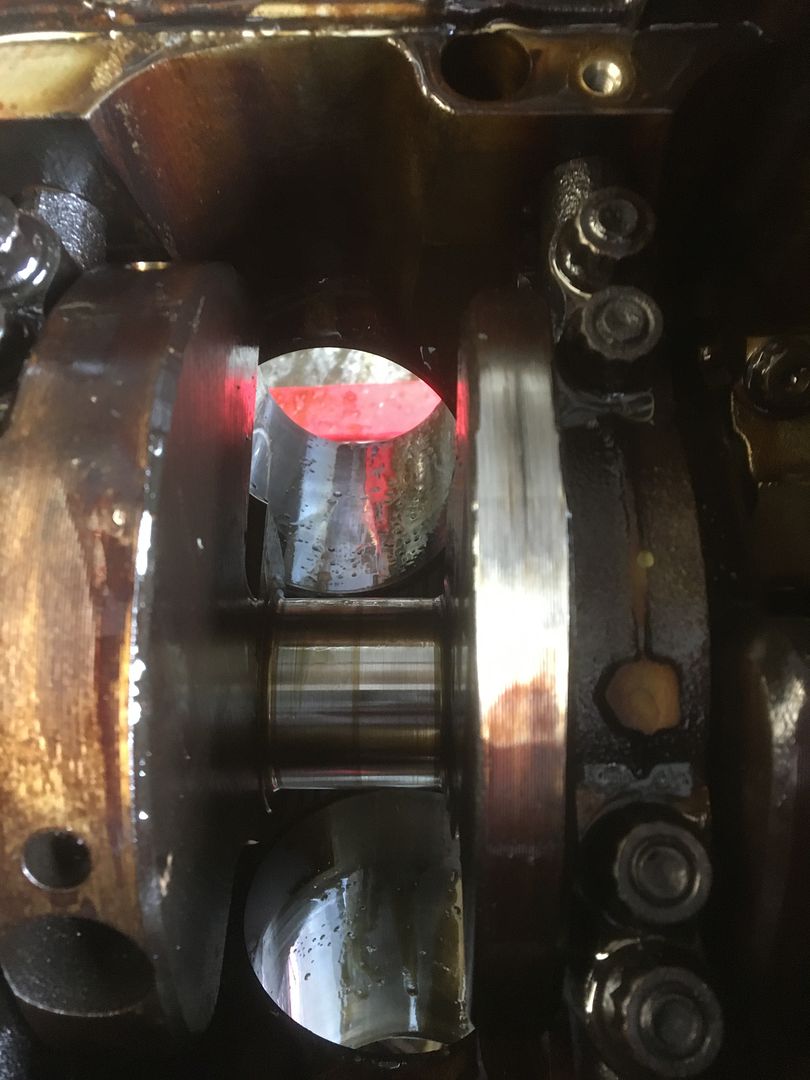

Cylinder 8, TDC:

Cyl 8 TDC

Cylinder 7 (the one with the leaky injector), TDC:

Cyl 7 TDC

Time for a nice V8 coffee table.

The resistance turning the engine over was at Bdc for cyl 7. Clearly exactly the same happened to my engine, as it did to Froggy's. Bummer.

[Edited on 21/10/17 by james h]

Iíve got plenty of spare rods if you want one . It wonít have done any damage . I slapped a rod in mine and itís fine and mines turboed

A big end bearing can give the same effect.

To check the big end when you rotate the crank and the piston stops moving for a period (almost like a flat spot) at the top this would indicate a big

end. Just to rule that one out....you did mention some knocking....

Knocking will be the underside of the piston scuffing the crank web .

In n/a form itís pretty tough to damage a 1uz unless itís got no oil in

Thanks, that would certainly explain the tight spot as well....

quote:

Originally posted by froggy

Knocking will be the underside of the piston scuffing the crank web .

In n/a form itís pretty tough to damage a 1uz unless itís got no oil in

quote:

Originally posted by froggy

Iíve got plenty of spare rods if you want one . It wonít have done any damage . I slapped a rod in mine and itís fine and mines turboed

Pretty straight forward job . Just need to check the old head bolts for any aluminium from the block threads and clean them with a tap and airline before building . Gasket sets and bolts are cheaper to have shipped from America than here as theyíre hard to find anything non genuine

Going back to the original question - I can't turn my V8 over by hand, even with the plugs out I need a wrench and a good 20lbft. My 3SGTE turns over a bit easier, but that's not surprising as it has 4 fewer cyls with 1/2 the ring friction.

quote:

Originally posted by coyoteboy

Going back to the original question - I can't turn my V8 over by hand, even with the plugs out I need a wrench and a good 20lbft. My 3SGTE turns over a bit easier, but that's not surprising as it has 4 fewer cyls with 1/2 the ring friction.