Engine will only start when the idle screw is turned all the way in, but still very lumpy and eventually cuts out. Turning the screw out and it doesn't start at all.

Does that mean a smaller Pilot Jet? Or something else?

Still trying to tune carbs...

Engine will only start when the idle screw is turned all the way in, but still very lumpy and eventually cuts out. Turning the screw out and it

doesn't start at all.

Does that mean a smaller Pilot Jet? Or something else?

Are you starting with the choke?

choke does make it a little easier, but still requires screw turned in.

You'll need the choke for a little while, try idle screws at 1 and 3/4 turns out, are you running dizzy or mega jolt?

I quests if its dizzy you may need some vacuum advance.

Where is your needle posisions

I found that you can richer up by lifting the needle a bit

Ultimately you will need to rolling road it

running megajolt, timing advance at 12

needle in middle, OK for WOT.

Will get it to RR eventually, but would be nice to get it at least starting OK.

Dose the engine turn over fast enough

What fuel pump are you using bike pump i hope ?

yes, bike pump. battery may be a shy of fully charged after the continued retries, so may be worth waiting until the morning before trying again and

getting the engine up to temp on the choke.

Will try increasing the Throttle position up a little also - currently 3% according to TPS, seeing as seems to run better with a little throttle.

What size are your main jets my carbs are zx9r's and they have 1.7mm jets with 3/4 turn out on the air screws

Also have you balanced the carbs you will have problems if not

1.7 jets were way too rich, for some reason. Ended up with 120 main jets to satisfy the AFR at WOT.

the fact that the main jet is so much smaller than what I expected it to be makes me think the pilot should be smaller too.

It does seem to still smell rich at idle, however lumpy, especially when I turn the screws out.

Re balancing - I've not separated the carbs so how would I balance then?

You will need a balance gauge you balance no 1 and 2 carbs then 3 to 4 then 2 to 3

New Motorcycle Carb Carburettor Vacuum Balancer Gauge 2 / 4 Cylinder Gauges Kit

Something like these if you havs balance pipes in your manifold

do a search on here there is lots of info how to make your own

[Edited on 14/9/13 by jacko]

I've already got a carbtune kit.

No pipes on manifold

ordered new vacuum nipplesadaptors from

MorganCarbtune

will see how unbalanced they are when they arrive

[Edited on 14/9/13 by RobBrown]

1.2 jet seems incredibly small and potentially running very weak, my pinto ended up at 1.65 jets with the free flowing filters on.

Trouble starting I would be looking at float height as a priority and putting main jets at 1.55 to start with too and as get them synced as soon as

you can get them to run at 3 or 4k

If the carbs are unknown as in cleanliness I would be stripping and cleaning them thoroughly as well and don't be surprised if you have to do

more than once and be meticulous in keeping your work area clean and tidy and do one carb at a time  there are plenty of YouTube videos that show

how this is done too.

there are plenty of YouTube videos that show

how this is done too.

I wouldn't even be looking at afr just yet concentrating more on plug colour

Just my 2 pennenth and hope you get sorted soon

If you don't understand how carbs and the different functions different jets do in the rev range, Dan explains it really well

HERE in fact his whole motorcycle course is worth a read for anybody interested in bikes.

Cheers

Rich

[Edited on 15/9/13 by RichardK]

Thanks for the advice Rich

I started with bigger jets(1.75), it ran but bogged down under acceleration. Bought AFR meter, and discovered was running too rich at WOT, so have

slowly come down in jet size so that WOT was correct AFR. That's when it stopped starting and idling.

In the midst of all this I've fitted MegaJolt - just because I was convinced timing and Dizzy was causing some of the problems

Can get it to start on the choke, but very lumpy and will eventually stop if not feathered on the throttle enough.

I'm obviously missing a piece of critical info as I too believe 1.2 is too small for a 2.0l pinto, based on the research I've done.

With the bigger jets the plugs were very wet and black.

With the 1.2 jets they are dryer and better. Practically everything is telling me 1.2 is correct even though I'm convinced like you that they

are too small - apart for the starting issue.

Rob

Something else to consider is the fuel contamination. If its more than 6 months old it could be blocking the idle jets, and they'll need to be

blown through, and the system drained. Make sure the fuel is fresh and you have a filter pre and post pump.

Speaking from my own experience

Good luck

fuel has been in sealed jerry can - does that matter? Will it still be contaminated?

filter pre and post pump

Going to take off and clean carbs through, just to be sure, just so I can be confident of answering these suggestions.

Should be able to check balance as well by next weekend

Have you blocked your air correctors? We have seen this done before, it does increase fuelling even with a small main jet, but makes the fuelling rich

at near full throttle.

If you have blocked them, unblock them and try 1.8mm mains with needles dropped to second from lowest position.

What AFRs are you aiming for at light throttle and full throttle?

[Edited on 15/9/13 by BaileyPerformance]

yes blocked, they came that way.

Just stripped carb down - 2 of the 4 idle mixture screws rubber O rings split and need replacing

Was trying to keep AFR at around 13, but found most jets caused AFR to drop to 9.

1.2 Jets kept it at around 11.5

Will try unblocking before I put it all back together. Can always block them back up again afterwards.

[Edited on 15/9/13 by RobBrown]

I have played with Megajolt cranking advance to make engine turnover easier

Check your getting full choke when you pull the cable

Also choke is not effective on bike carbs if you also apply throttle

quote:

Originally posted by RobBrown

running megajolt, timing advance at 12

Im betting its the air correction holes some carbs like them blocked and some don't

quote:

Originally posted by jacko

Im betting its the air correction holes some carbs like them blocked and some don't

Just drilled them out. they were closed off with solder or aluweld or something, so needed drilling. I was careful as I didn't know how far to

go.

All the brass inserts came out cleanly but the bottoms are all shot. Can I get replacements for these? Or can I run without the insert. I notice that

they are not displayed on the standard Carb schematic and parts list.

I suspect that without the insert there will now be too much air getting in.

I work near a Yamaha dealer, so will pop in there tomorrow to try my luck.

Update...

Fuel drained, old fuel in tintop, new fuel bought

Filters cleaned

Carbs striped down cleaned and put back together carefully

replacement idle screw rubber washers fitted (splits in 2 of the 4)

air correction unblocked

165 main jets fitted

needle clip on middle setting

screws turned out a variety of settings, initially 2, then back to half, then 3 then 4.

but still wouldn't start, even had trouble coaxing it to start on the choke

plugs wet

but... will start with a squirt of carb cleaner down each carb and will then run, but as soon as I try and go back to idle again it dies.

Still convinced that the 165 jets are too big I can smell the fuel coming out of the exhaust, but not had the AFR on it at this stage to check.

So it must still be to do with not getting the idlepilot circuit mixture right to allow it to start.

Interestingly can't get the carbtune synchroniser to register any readings, from the new adaptors fitted to the manifold (might be a leak in the

tubes, although sucking hard seems to do the trick (Oo-er))

Engine seems to be blowing back through carbs at idle ( I would naturally expect it to be sucking the same as it does at higher RPM)?

I've got bigger pilot jets to fit, which I could try (17.5), but not convinced at this stage that it's going to make any difference

Any suggestions gratefully received at this stage

My carbs spit back until the engine is hot

I don't need to use the choke to start mine

you could try dropping the main needle to the lowest on the clip

If all this dose not work i would give Bogg Brothers a phone call they are experts on r1 carbs

All this is i can think off

It looks like someone has played with the carbs before you got them if the air holes where already blocked

Jacko

[Edited on 18/9/13 by jacko]

Sorry - not the carbs spitting. I've had that too when it has been too lean

Just something that I hadn't really noticed before the engine blowing back though the carbs before anything gets started, whilst trying to turn

over. How does any fuel get into the cylinder if the engine is effectively blowing it away?

It just made me question whether the cam timing was right, once it started with the carb cleaner everything seemed to be OK, so timing must be OK.

quote:

Originally posted by RobBrown

Sorry - not the carbs spitting. I've had that too when it has been too lean

Just something that I hadn't really noticed before the engine blowing back though the carbs before anything gets started, whilst trying to turn over. How does any fuel get into the cylinder if the engine is effectively blowing it away?

It just made me question whether the cam timing was right, once it started with the carb cleaner everything seemed to be OK, so timing must be OK.

quote:

Originally posted by jacko

quote:

Originally posted by RobBrown

Sorry - not the carbs spitting. I've had that too when it has been too lean

Just something that I hadn't really noticed before the engine blowing back though the carbs before anything gets started, whilst trying to turn over. How does any fuel get into the cylinder if the engine is effectively blowing it away?

It just made me question whether the cam timing was right, once it started with the carb cleaner everything seemed to be OK, so timing must be OK.

From what you say it sounds like timing as you say, i would check all engine timing

quote:

Originally posted by jacko

quote:

Originally posted by jacko

quote:

Originally posted by RobBrown

Sorry - not the carbs spitting. I've had that too when it has been too lean

Just something that I hadn't really noticed before the engine blowing back though the carbs before anything gets started, whilst trying to turn over. How does any fuel get into the cylinder if the engine is effectively blowing it away?

It just made me question whether the cam timing was right, once it started with the carb cleaner everything seemed to be OK, so timing must be OK.

From what you say it sounds like timing as you say, i would check all engine timing

Is the engine trying to stop turning over like a flat battery ? mine use to do this it was the timing advance too far on the dizzy

It took me a couple of attempts to properly clear my idle jets. The holes in them are so small, and are very easily blocked again, so make sure the

fuel hoses or filter/s are not old and breaking down.

As far as i know, normally you don't need to increase idle jet sizes, so wouldn't advise drilling them just yet. My guess is they're

still blocked, or perhaps you've got leaks on the inlet manifold, drawing in too much air (test with wd40)?...

Keep us informed

Don't panic, not drilling anything...

But some progress made...

New idle jets fitted, size 17.5 (which I had bought a few months ago, when I first started trying to get them running).

It now starts, but increases in RPM a little; runs for about 10-15 seconds then slowly comes back to rest.

Won't start again straight away, but after a few minutes does the same again, starts then dies

I can only get it to start with the idle mixture screw in a specific position. half a turn either way and it won't start as easily.

[Edited on 18/9/13 by RobBrown]

[Edited on 18/9/13 by RobBrown]

Are the diaphragms making a good seal

quote:

Originally posted by jacko

Are the diaphragms making a good seal

Any joy Rob?

Update please

I've got it starting but it is stopping after about 10 seconds, now not increasing in RPM.

I have taken the manifold off, discovered it had a slight bow, so have used a liquid gasket, rather than the paper one.

Applied red grease to top coverdiaphragm seal

I've drilled out the ac to about 0.5mm (or thereabouts) - all my really small drill bits have broken, so not sure which one I've used.

smells very rich still - I've got 185 jets fitted and needle on 2nd from top setting (I know BaileyPerformance suggested 2.0mm, but I've not

got a 2mm drill bit). I had needle on top position, but spat back and struggled to start.

Still suggests an air leak somewhere but can't now imagine where?

It won't start straight away after stopping - feels more like flooding than a vacuum leak, smells very rich as I say.

Incidentally no filter fitted yet.

Any more suggestions welcome.

I wouldn't worry about main jet sizes at this stage, as they play no part in starting and idling which is the job of the pilot/idle jets (of

course).

Have you checked the plugs as soon as the engine stops? Are they wet, black, dry, white? Also, are the bowls empty? Do you know what the fuel

pressure is (should be <3psi)?

To check for induction leaks, you need to get the engine running (!) and spray wd40 around suspect areas. A rise in engine speed will indicate a leak

as the wd40 is drawn in and burnt.

Is it running on 4 cylinders, or obviously misfiring?...

Apologies - for so many questions

wd40 seems to not make any difference, for the 10 or so seconds the engine runs.

plugs look OK - one dry the other mildly moist, but not black or sooty.

Discovered one clogged with the liquid gasket from earlier - cleaned but made no difference.

Will only start with the choke on, but left on or released off makes no difference to the fact that it dies out after a while.

A bit of a long shot, but I read, via a google search, that coil failures of this type occurred occasionally. Might try looking for a new coil

tomorrow.

Just to add - running with an R1 fuel Pump - doesn't fill the bowls on the next start up, so not a lack of fuel issue as far as I can tell - Is

it possible to have too much pressure? with an R1 pump?

[Edited on 20/9/13 by RobBrown]

Not sure about r1 carbs but mine had 3 very small holes that are usually covered by the butterfly disc when in the closed position that connect to the

mixture screw, so blew them out when the carbs were stripped and these view fine holes were blocked and gave exactly the problem you describe but

these were keihin carbs, also used compressed air to blow through, but can't express strongly how important it is to get the float height correct

on bike carbs, sometimes you can use a thin clear tube stuck on the drain bowl and then looped back up and taped to the side of the carb and then open

the drain screw and fuel will flow up the tube and settle at the same point of where it is inside which can be checked against the service manual

specs.

Hope you get it sorted.

Cheers

Rich

quote:

Originally posted by RichardK

... sometimes you can use a thin clear tube stuck on the drain bowl and then looped back up and taped to the side of the carb and then open the drain screw and fuel will flow up the tube and settle at the same point of where it is inside which can be checked against the service manual specs.

are you sure your ignition is ok?

connect a strobe light to one of the HT leads, run the engine and watch the strobe, make sure the strobe keeps flashing as the engine dies to confirm

ignition is OK

Yes, even slows as the engine slowly dies

Could it be bin settings on the MegaJolt and the advance? Only because I've noticed the sudden drop in advance between each bin.

Running at 2.5k the advance is 25,

but my bin jumps in steps of 1000RPM

Only just spotted this read so a few ideas based on my nightmares setting mine up.

When you say you have cleaned the jets etc have you left them overnight in carb cleaner to soak.I blew mine through numerous time w compressed air and

they kept blocking. I was amazed at how much dirt the cleaner got out.

Where are your float heigh levels relative to the jet to where the jet enters the carb. The level should be below this.

When you blip the throttle do all 4 diaphragms raise?

How close is the balance across all 4- they need to be very close.

My pinto has a bit of a missfire pop from the exhaust at anything above an AFR of 13, 12 .5 seems to be about perfect, but it is then a bit high on

co. I've heard of the same thing on other pintos

Does the engine idle on the throttle? Any miss firing or popping back through the carb?

quote:

Originally posted by davidimurray

Only just spotted this read so a few ideas based on my nightmares setting mine up.

When you say you have cleaned the jets etc have you left them overnight in carb cleaner to soak.I blew mine through numerous time w compressed air and they kept blocking. I was amazed at how much dirt the cleaner got out.

Where are your float heigh levels relative to the jet to where the jet enters the carb. The level should be below this.

When you blip the throttle do all 4 diaphragms raise?

How close is the balance across all 4- they need to be very close.

My pinto has a bit of a missfire pop from the exhaust at anything above an AFR of 13, 12 .5 seems to be about perfect, but it is then a bit high on co. I've heard of the same thing on other pintos

Does the engine idle on the throttle? Any miss firing or popping back through the carb?

I know nothing about megajolt could it be that that's cutting out and not the carbs ?

If it was me i would refit the dizzy and try that again

Jacko

quote:

Originally posted by jacko

I know nothing about megajolt could it be that that's cutting out and not the carbs ?

If it was me i would refit the dizzy and try that again

Jacko

I wish you lived in hull i would have come and looked at it for you

Dose the engine stop as if the electrics have cut or if its run / running out of petrol

Jacko

Unplug your megajolt, the EDIS will default to fixed timing of 10 degrees which is find to get it running.

....this assumes you have installed the trigger wheel correctly as we have seen loads that are in the wrong place or badly mounted vr sensor

Definitely try removing the idle and pilots and soaking in carb cleaner over night. I was amazed at the difference it made to mine. Mine are zx6r but

after blowing them through my idle screws had to be 4-5 turns out, after soaking in cleaner I now only have them 2.5 turns out. My pilots also kept

blocking and again carb cleaner sorted them out. At the same time I would also spray some carb cleaner down the carb and check that it drips down

through the idle and pilot passages.

Really stupid question, but have you confirmed the fuel pump is running constantly. It couldn't have been wired to the start postion by accident

could it? Next time it dies try opening the screws on all the float bowls and seeing if there is fuel in all of them.

I assume that you have the throttle stop adjuster fitted.May sound stupid but I have seen carbs for sale with them missing

If it runs at full throttle then I wouldn't worry about the mains yet and it would point to a problem with the idle/pilots. Popping back through

the carbs on mine was as a result of a lean miss fire and carb balance.

Are you using the throttle to start the engine?

Keep at it, took me a while to sort but now starts instantly with or without choke depending on the temp.Can even get a 20p piece balanced on the

rocker cover.

I probably have some AFR traces for starts and you're welcome to a copy of my jolt map if it helps. Mine is an 1800 but won't be far off.

quote:

Originally posted by RobBrown

quote:

Originally posted by davidimurray

Only just spotted this read so a few ideas based on my nightmares setting mine up.

When you say you have cleaned the jets etc have you left them overnight in carb cleaner to soak.I blew mine through numerous time w compressed air and they kept blocking. I was amazed at how much dirt the cleaner got out.

Where are your float heigh levels relative to the jet to where the jet enters the carb. The level should be below this.

When you blip the throttle do all 4 diaphragms raise?

How close is the balance across all 4- they need to be very close.

My pinto has a bit of a missfire pop from the exhaust at anything above an AFR of 13, 12 .5 seems to be about perfect, but it is then a bit high on co. I've heard of the same thing on other pintos

Does the engine idle on the throttle? Any miss firing or popping back through the carb?

Thanks for your help

No - not left them in overnight. the Main jets are new, so would only be the pilot and air jet. Could try this tonight

The engine will run if the throttle is fully opened up, just won't idle if left at 10% TPS or lower - having said that is throttle adjusted higher it won't run indefinitely.

fuel level is higher than the join between the bowl and the carb. not measured float itself yet.

I can't get my Carbtune to register at the moment, to check balance - not sure whether it's related or a duff carbtune, which has been sitting around for a couple of years.

A few misfire pops at different times, mainly when I open the throttle.

All four sliders move when I blip the throttle.

My main issue is the cutting out after a very short amount of time.

The only significant change I've made recently is the MegaJolt, because I thought my issues were to do with the Dizzy and the timing - but that seems to firing OK.

[Edited on 21/9/13 by RobBrown]

quote:

Originally posted by BaileyPerformance

Unplug your megajolt, the EDIS will default to fixed timing of 10 degrees which is find to get it running.

....this assumes you have installed the trigger wheel correctly as we have seen loads that are in the wrong place or badly mounted vr sensor

quote:

Originally posted by jacko

Dose the engine stop as if the electrics have cut or if its run / running out of petrol

When its running are the slides moving up and down not sticking im thinking out allowed

quote:

Originally posted by jacko

When its running are the slides moving up and down not sticking im thinking out allowed

quote:

Originally posted by RobBrown

fuel level is higher than the join between the bowl and the carb. not measured float itself yet.

[Edited on 21/9/13 by RobBrown]

A quick google suggests 4.1mm below the joint? Obviously I don't know the age or model of your carbs but do you own research, not many posts that

do it the way I'd it with the tube the workshop manual does the upside thing and measure.

Hope you get it sorted.

Cheers

Rich

quote:

Originally posted by RichardK

A quick google suggests 4.1mm below the joint? Obviously I don't know the age or model of your carbs but do you own research, not many posts that do it the way I'd it with the tube the workshop manual does the upside thing and measure.

Hope you get it sorted.

Cheers

Rich

Jets soaked in cleaner overnight.

Floats checked and are all perfectly aligned.

But still the same cut out issue after 10-20 seconds

Now you know when you remember a crucial piece of info...

The reason that I was originally at 120 main jets is because I had these carbs running consistently enough to be able to AFR them at WOT and get them

running. Now I didn't have the cutting out problem then.

The only thing I have changed since then is that I moved back to a stock cam (rather than a lumpy one) and moved across to MJ as I had real issues

with the Dizzy (and I had had it on the shelf for a couple of years meaning to fit) - and it never started when I lined-up all the arrows for TDC.

I'm slowly convincing myself, especially what I've seen over the weekend with changing needles and jets and screws not making a blind bit of

difference to the cut out issue, that it's an MJ problem somewhere, so tomorrow:

have you tried it with MJ disconnected so that its just the EDIS4 plugged in ?

this should run a fixed 10° advance as a 'limp home mode'

quote:

Originally posted by mcerd1

have you tried it with MJ disconnected so that its just the EDIS4 plugged in ?

this should run a fixed 10° advance as a 'limp home mode'

how solid is your VR sensor mounting ?

a few folk have had issues with it moving/vibrating just enough to stop working (needs to say about 1mm from the trigger wheel from memory)

quote:

Originally posted by mcerd1

how solid is your VR sensor mounting ?

a few folk have had issues with it moving/vibrating just enough to stop working (needs to say about 1mm from the trigger wheel from memory)

I still think float height is your problem, no venturi effect over the idle jets mixing not enough air with fuel so neat fuel is just been delivered

and flooding. This also explains why it runs better with smaller mains fitted too.

If this does turn out to be the problem dump your oil too as it could be contaminated if it's been flooding alot.

Hate to say this but I would whip the carbs off and set the floats to exactly to spec, I saw a video recently where a guy used a bar code off a cereal

packet at marked the height on the fine line and this cardboard was easier to get I between the carbies, neat trick I thought.

I have in the past also used an old needle valve and glued up the sprung pin and used this one to set the float height, when correct just swap it back

to the proper one. This way it doesn't matter what angle you hold the carbs while adjusting the float tang.

Really do you you get this sorted mate as I know how frustrating things like this can be.

Cheers

Rich

Thanks Richard

I'm in the process of just making sure everything else is OK.

I'm also not sure what height to set the floats to. The 4.1-5.1mm figure is for when the angle is close to the original bike mounting angle. I

could just lower them all to a consistent height and see if that makes a difference. They are all currently at 4.1mm (using the upside down method)

I'll hopefully know tonight whether the other things have worked, which are:

New Spark Plugs

Repositioned VR sensor

New Coil Pack

New Fuel filter between tank and pump (awaitng delivery of this before being able to test the rest).

This was the geezer in the video linky

You'll have to get that specific info about heights from the correct service manual, can't guess it mate.

Cheers

Rich

[Edited on 26/9/13 by RichardK]

quote:

Originally posted by RichardK

This was the geezer in the video linky

You'll have to get that specific info about heights from the correct service manual, can't guess it mate.

Cheers

Rich

[Edited on 26/9/13 by RichardK]

Can you show a picture of them fitted mate, not sure I understand, usually you try and get them so the joint is parallel with the ground. Although

that said I have been known to wheelie bikes a fair distance so doesn't seem to make that much difference.

I'd get a standard manual and set it to that and leave it alone, it was just your comment about the level being above the joint that doesn't

seem right.

Cheers

Rich

According to the manual the float heights should be 4.1-5.1mm. My carbs using the manual method are all set correctly at 4.1mm.

However the manual reflects them being fitted to a bike, which has the carbs in more of an upright position .

I have fitted the carbs to the car horizontally so that the float bowls are level, which is a different orientation to when they were on the bike.

Using the clear tube in the bottom of the bowl method the level of the fuel is above the join of the float bowl.

If the level is meant to be below the join then it could mean raising the float level by about 10-15mm to achieve this - I've not read anywhere

that this needs to be done when fitting bike carbs to cars is my only worry.

To be honest changing the float level will be my last resort tonight, once I've been able to assess whether the other things have made a

difference - and I don't remember having the same cutting out issue when I first installed the carbs with theh Dizzy fitted.

Will let you know later...

http://www.boggbros.co.uk/gallery5.html

I wonder what they do to get these working

I think I have the answer...

One of the things I was waiting for in the post today arrived... A compression tester. The result may explain the low rpm cut out issue...

Cylinder 1 = 50 PSI

Cylinder 2 = 0 PSI

Cylinder 3 = 150PSI

Cylinder 4 = 100PSI

I think I have a problem in the front two.

I won't know whether it is valve related or piston related until I get the head off will I - unless you guys know of a smart way of checking?

I've not tried the new coil or plugs yet. Awaiting your recommendations.

I've got another head I can swap in if it's the valves, but rings is a messy job having to unbolt all the bottom end

Sh1t, sorry to see those figures, at least progress is being made.

Cheers

R

[Edited on 27/9/13 by RichardK]

Spoon of oil down each plug hole, if compression increases its the rings

If not head off check gasket ( you'll change this anyway) then upend head and fill chamber with fluid to see if valves are seating

Did you check the compression with the throttle open? I'm thinking you did it with the throttle closed, and the throttles on cylinders 1 and 2 are so far out of balance with cylinders 3 and 4 that no aid is getting on hence no compression. This would also not help it starting.

The compression check was done with all spark plugs out and the fuel line disconnected. Admittedly the throttle position was closed. Are you saying that teh balance would impact the compression readings to this extent.

quote:

Originally posted by RobBrown

The compression check was done with all spark plugs out and the fuel line disconnected. Admittedly the throttle position was closed. Are you saying that teh balance would impact the compression readings to this extent.

Personally I wouldn't have thought having the throttle shut would cause 1 to be zero, but I'll bow to Baileys experience as he's far

more knowledgeable than I, another tip to get the butterflies close is to open up the idle screw a little and then use a small strip of copier paper

in the bottom of the mouth and adjust each butterfly until you can just pull the paper out with the same kind of resistance on each carb and then use

the idle adjustment screw to close all of them a little back to being very nearly shut.

If there are tiny holes in the mouth directly where the edge of the butterfly closes over it make sure they are clear whilst you're playing and

all of these holes should be covered uncovered equally on each carb but the paper trick should get you close.

Wish I was closer mate or I'd give you a hand.

Cheers

R

[Edited on 27/9/13 by RichardK]

[Edited on 27/9/13 by RichardK]

quote:

Originally posted by BaileyPerformance

yes, it will, you MUST do a compression test with half or more throttle.

.

quote:

Originally posted by RichardK

Wish I was closer mate or I'd give you a hand.

Took carbs off. Compression still the same.

Head now off - Can now see that exhaust valves are not seating properly on 1 and 2, The inlets are OK. Might explain an overly rich AFR reading ?

Will check the other head on the shelf tomorrow.

Some progress at least. Hopefully tomorrow evening We'll have it all back together.

Well.

Everything is back together.

Compression on no 2 cylinder is 70-100, not great, but better than 0. All I did was remove the exhaust valve, and lightly brush down both edges with

wire wool. I retested with Fuel in the port and it seems to have cured the leak. I replaced the Valve Stem seals on this and no.1 exhaust valve.

Balanced the carbs on the bench using 2 3mm drill bits, they were all out by a fair bit.

It definitely idles a lot smoother now, but still cuts out at low RPM. It was running for so long that I thought it had been fixed but no.

when it does idle I'm now getting more pops and farts than before.

Slightly disappointed. It was a very messy job.

Number 1 still 50? I thought as a rough guide compression should be above 100  think you should have lapped in all the valves while you had the

chance, also confirmed that the chamber held paraffin /fuel with the valves shut.

think you should have lapped in all the valves while you had the

chance, also confirmed that the chamber held paraffin /fuel with the valves shut.

That's

Rich

quote:

Originally posted by RichardK

Number 1 still 50? I thought as a rough guide compression should be above 100think you should have lapped in all the valves while you had the chance, also confirmed that the chamber held paraffin /fuel with the valves shut.

- will mean a new head gasket and head bolts.

- will mean a new head gasket and head bolts.

Bolts are ok to re use 2 or 3 times in my view but as you don't know the history you're probably wise to replace.

As we're both unsure what is the correct float height, I wonder if some kind sole wold stick a clear tube on the bottom of there overflow and let

you know the reading?

Sure there are plenty of R1 carb setup out there, mine are honda hornets so can't help.

Cheers

Rich

Well, Well, Well...

We seemed to have sorted it.

I noticed that the fuel pump was clicking intermittently, even though the engine wasn't running, this was after I lowered the floats

yesterday.

So I fitted a fuel regulator just before the carbs. It's a cheap dial type

(like

this), so wasn't really convinced it would make much difference.

It seemed to work then cut out again after about 2 minutes of just on idle.

I tried again and just let it run, it started to faulter again so I blipped the throttle and then it just ran and ran

. I don't know what RPM

it was running, but seemed a lot lower than 2k. I didn't have the laptop fitted as I was just closing everything up for the night

. I don't know what RPM

it was running, but seemed a lot lower than 2k. I didn't have the laptop fitted as I was just closing everything up for the night

The proof of the pudding will be trying to start it up again tomorrow, and it continuing to run.

I probably now need to sync the carbs properly, before starting to fine tune the jets.

Incidentally compression on no 1 is now 80PSI - still not great I know. I've another better head being rebuilt, for next weekend

Thanks all for your help. Will let you know if I get any further problems with it over the next couple of days.

Mmm I had one of those and it reduces flow as well as pressure, what bike pump are you using, you're not using the mechanical pinto pump are

you?

Off to look through previous posts...

Glad you're getting there

Ok bit of a recap needed, what is your float height at now, below the joint?

Main jet size?

Idle screw set back to standard?

Don't forget to dump the oil if you think it could be thinned with petrol.

My instinct is saying the floats are now closing off the fuel in the carbs hence the occasional blip of the fuel pump which mine does from time to

time but more likely is that you're very close and needs tiny bit more of adjustment. Just to ensure they all shut at the correct level, it could

of course mean a float stuck just for a moment and has now cleared which would be nice.

Nearly there!

Cheers

R

[Edited on 30/9/13 by RichardK]

quote:

Originally posted by RichardK

Ok bit of a recap needed, what is your float height at now, below the joint?

Main jet size?

Idle screw set back to standard?

[Edited on 30/9/13 by RichardK]

Hi Rob

In the picture the tps sensor on the end of the carbs is disconnected so I'll make the assumption your running map but didn't see any method

of taking the vacuum collectively off all 4 intake runners? I used tps and 2d map and worked great with the megajolt.

You are showing the float level on cyl 4 which looks high to me but we could do with some kind soul test there working carbs, I did notice that in the

video carb 1 was spitting and popping fuel which usually means float height is to high so is this carb got a different height to the other 3?

Spitting can also be caused by bad valve timing, have you got an adjustable vernier cam fitted, I don't profess to know how this is done as I

have a good mate in Mookaloid who helped me do mine but did involve a lot of precise adjustment and a dial gauge down a plug hole! I remember it took

a while but it idled sweet after that.

Just a couple of things I noticed.

Cheers

Rich

I am using tps, just disconencted in the picture as I had just taken them off and put them back again. It looks like it was disconnected in the vid

too.

All the carbs are the same level as shown.

The spitting stops once the engine has warmed up.

Vernier fitted - but not touched this - just set to TDC markings on teh head and block.

[Edited on 1/10/13 by RobBrown]

[Edited on 1/10/13 by RobBrown]

Spitting at any temp isn't right, but does give us the clue of incorrect float height or valve timing.

Maybe stick a another post on here specifically asking for a float height check using the tube method or asking if there is anybody close that you

could go with your bit of tube and check

Cheers

Rich

TI'm finding this thread very informative. It's also completely persauded me not to spend money on bike carbs and a manifold, setup etc and to stick with my 38/38 dgav downdraught which starts first time.

If your dgav or degas is working for you then fine, I changed from my dgas as I wanted better performance and better mpg which my bike carbs gave over

the dgas and also their is a bit of bling factor

I personally think Rob's been sold some carbs that have been messed about with previously and he's suffering as a result, if you can get

some carbs off a running bike and the fuel pump, chuck in jets to suit your motor and in my experience that will be good enough to get you to a

rolling road.

I wouldn't let this put me off, I haven't regretted my change one bit.

Cheers

R

quote:

Originally posted by RobBrown

Vernier fitted - but not touched this - just set to TDC markings on teh head and block.

quote:like richard says this is probably just a dud set of carbs

Originally posted by Not Anumber

It's also completely persauded me not to spend money on bike carbs and a manifold, setup etc and to stick with my 38/38 dgav downdraught which starts first time.

quote:

Originally posted by RichardK

Spitting at any temp isn't right, but does give us the clue of incorrect float height or valve timing.

Maybe stick a another post on here specifically asking for a float height check using the tube method or asking if there is anybody close that you could go with your bit of tube and check

Cheers

Rich

quote:

Originally posted by mcerd1

btw Rob, where did you get these carb's ?

you seem to have had a lot more than your fair share of issues with them

[Edited on 1/10/2013 by mcerd1]

can you get your hands on a dial gauge or two to check the timing properly ?

(I'd lend you one if you were a wee bit closer  )

)

you'd be amazed how far out they can be on the timing marks, so its worth checking before you blame the carb's again...

quote:

Originally posted by mcerd1

can you get your hands on a dial gauge or two to check the timing properly ?

(I'd lend you one if you were a wee bit closer)

you'd be amazed how far out they can be on the timing marks, so its worth checking before you blame the carb's again...

^^but adjusting the trigger wheel will not sort the timing of the cam to the pistons - its the whole point of the adjustable cam pulley

if your using the stock cam its not tuned enough to matter within the specified tolerances (i.e. the lowest common denominator approach to engine

tuning)

if your using a performance cam changing the timing by as much as 2° could make a big difference to the way it runs as the margin for error is much

smaller

you can get a decent enough gauge fairly cheap - you'll only need one and one of those big protractors you get with the cams or the adjustable

pulleys.

machine mart have ones for about £15 + £10 for the magnetic stand - but google for 'dial test indicator' and you'll get lots of choices

(the plunger type ones the best all rounder)

burton power have a guide on page 6 of the catalogue: linky

or I can send you some more detailed stuff for the pinto if you send me a u2u with your e-mail address

and as a bonus it'll also let you check your real TDC position against the trigger wheel (not that it matters much if its out a little, you can

just adjust the software to compensate)

[Edited on 1/10/2013 by mcerd1]

^^ got it. Penny only dropped when I stared at it.

Will try and get a dial gauge.

Shining the light down the spark plug opening I can see that the top of the stroke isn't exactly spot on with the crank timing marks.

I made a small adjustment, just visually and it has stopped spitting

BTW using the standard Cam for now - until I understand what's going on. Learning every day

Noddy question - With the dial types on ebay(Dial test indicator DTI gauge &' magnetic base stand clock gauge TDC

TE107TE108), does the pointer at the bottom extend out. Just wondering whether they'll extend long enough to go through the spark plug

opening?

^^ you'll need to make something to stick down the spark plug hole, i've seen a few versions that used a hollowed out old spark plug a a

slide (if it slides well its less likely to jam)

but you don't actually need a dial gauge to find TDC (it's needed more for the valves than anything else)

you can make up a solid bar that screws into the spark plug hole and sticks out just enough to stop the piston before TDC (often just an old spark

plug with a bolt welded on the end)

you then fit your protractor to the crank and a pointer

turn the engine forwards slowly till it just touches the stop - take a note of this angle

then turn the engine backwards slowly till it touches the stop from the other side - take a note of the angle

true TDC is the the middle of these two angles

so you can remover the stop, turn the engine to the calculated TDC position and then zero the protractor (without moving the crank)

if you think that sounds complex its no worse than you need to do with the dial gauge - as the piston actually 'floats' for a few degrees

you need to do a similar procedure to find the true TDC

[Edited on 2/10/2013 by mcerd1]

Just tape a wooden skewer or similar to the end of the dial gauge and stick down the hole and then set it up on the stand and zero it out at the

highest point of the piston stroke, takes a bit of fiddling but defo worth the time to get it spot on.

Cheers

R

So a bit of an update, over the last few days.

Carbs now sync'd up using a combination of devices

TDC on crank (using a tool rather than sight) shown to be exactly on the pulley mark - surprisingly!

With the megajolt disconnect and the choke on it idles sweetly . With the afr connected it appears that when the choke is off the

mixture is way too lean (up at around 20). I've refitted the filter just to bring the air flow back down a little

. With the afr connected it appears that when the choke is off the

mixture is way too lean (up at around 20). I've refitted the filter just to bring the air flow back down a little

Main jet is drilled out to 2mm as recommended by BaileyPerformance earlier in this thread. Initial needle position at the lowest, but slowly moved up

to try and combat the lean issue. Air corrector at about 0.5mm

After everything done - I'm now not getting the stalling issue at idle which is good news. I feel as if I've got this under control

However the MJ is confusing things at the moment because I think the timing is out, so it just accelerates up to about 2500rpm - so may set it to 10

degrees across the RPM range for now, just to eliminate it.

Any recommendations for sorting the lean AFR at idle, with the choke off?

Rob

Hi rob, can post a screenshot of your mj map and also check that the rev limit isn't set at 2.5 within mj I know it is set low using the default

map to be on the safe side.

What is the plug colour like although wont be truly accurate as its not being run properly for a while just wondering if your afr meter is

accurate?

Glad you're making progress though.

Cheers

Rich

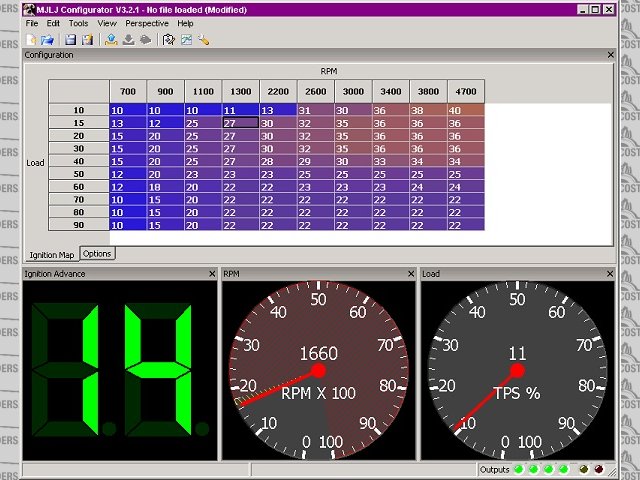

MJ Map, to try and replicate it unconnected

Description

The spark plugs are interesting. the first two plugs seem to indicate not complete burnrich as they are oily, but the rear two seem to indicate lean

as they are light in colour, not oily at all.

Wonder whether it is linked to the first two also being the ones with the low compression.

Have blasted through the pilot jets and holes with carb cleaner, but doesn't seem to make any difference to the cutting out off choke. However it

will now start and run if the throttle is feathered but still high AFR.