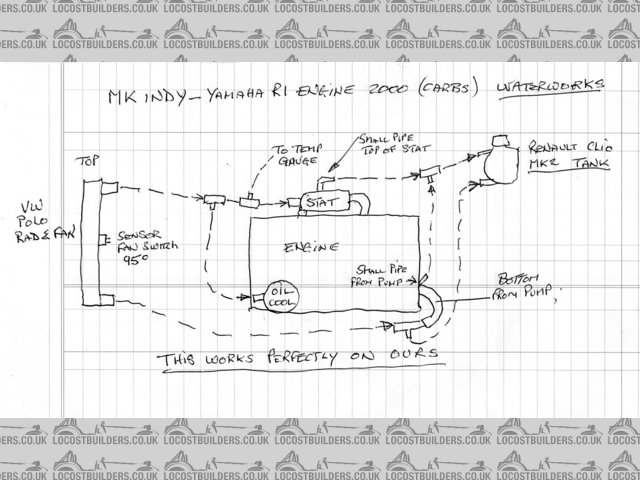

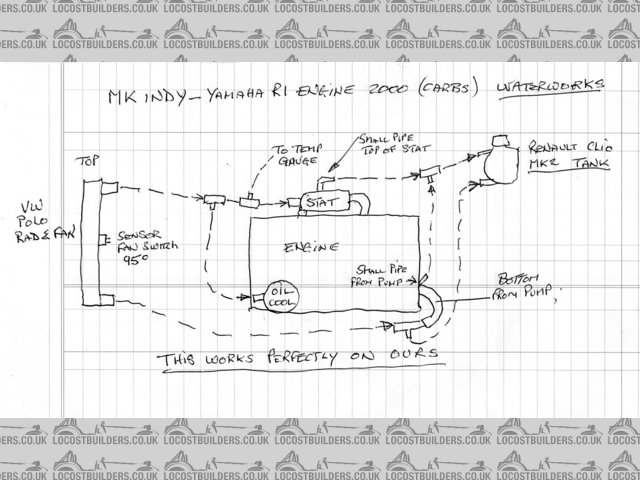

This is what we did on ours

But its a bike engine, should work on a car engine.

Good luck

René

Waterworks R1 Indy

I'm currently working on the cooling system of a project.

The project currently uses a vented radiator cap and recovery bottle but due various constants we cant get enough slope on the top hose to allow air

to be purged from the engine. Hence I was wondering on the possibility of a remove filler cap above the radiator with a bleed line from the engine to

the cap, with then a pipe down to the recovery bottle.

Has anyone used a system like this, or know of a suitable setup.

The filler cap would then either T into the top hose with a non-venting cap on the radiator, or be run from the radiator up to the cap.

Daniel

I take it the top of engine is higher than the rad.

First stage is drill either small vent bleed holes in the thermostat (either two 2mm to 2.5mm or a single 3mm hole) as this will make

filling and bleeding much easier and allow the thermostat to respond faster.

If you have a a copper/brass rad off a 1970s/1980s British car you may find the overflow fitting on the radiator filler neck is not soldered in

but a nylon or black plastic push fitting that wasn't intended to seal very well under pressure or vacuum. If this is the case connecting

on to this won't work.

To blank off the existing pressure cap just insert solid rubber washer ( ie a rubber disk) between the existing washer and the cap.

You can get fittings for radiator pressure caps that fit directly into the top hose (Car Builders Solutions sell them) but it would be a more

satisfactory solution to fit a header tank. The Rover 25 tank is a popular choice because it is small and easy to mount. It has two hoses the

bottom one goes to the bottom hose the top goes to the top outlet of the engine --- if the vent holes in thermostat ensure it will bleed

properly even with thermostat closed.

Hi

This is what we did on ours

But its a bike engine, should work on a car engine.

Good luck

René

Waterworks R1 Indy

This is what I used on mine, I had to re-weld the outlet pipe though as mine was a little loose and it leaked, hopefully just a one off though.

http://www.nfauto.co.uk/in_line_radiator_filler_neck.htm

quote:

Originally posted by Scuzzle

This is what I used on mine, I had to re-weld the outlet pipe though as mine was a little loose and it leaked, hopefully just a one off though.

http://www.nfauto.co.uk/in_line_radiator_filler_neck.htm

I sealed mine up because I don't need it but it could have been used if I wanted, I think I just got a ropey one and was just unlucky, easy

enough fix just running round it with the welder.

[IMG]http://i78.photobucket.com/albums/j106/scuzzlebutt-1/P1010011-4.jpg[

/IMG]

I could just use the expansion bottle to fill my cooling system but this does make life easier.

[Edited on 14/6/13 by Scuzzle]

[Edited on 14/6/13 by Scuzzle]

quote:

Originally posted by Scuzzle

I sealed mine up because I don't need it but it could have been used if I wanted, I think I just got a ropey one and was just unlucky, easy enough fix just running round it with the welder.

[IMG]http://i78.photobucket.com/albums/j106/scuzzlebutt-1/P1010011-4.jpg[ /IMG]

I could just use the expansion bottle to fill my cooling system but this does make life easier.

[Edited on 14/6/13 by Scuzzle]

[Edited on 14/6/13 by Scuzzle]

quote:

Originally posted by Scuzzle

This is what I used on mine...

http://www.nfauto.co.uk/in_line_radiator_filler_neck.htm

It might be better to keep it simple and avoid expense and complication

The problem with recovery bottles is small ones don't really work, the ones (Honda and other Japanese) that do work rely in the radiator

header tank having sufficient air space.

Pressurised expansion tanks are now pretty well universal they only require a connection to the highest point on system and a connection to the

cold side of the system ie water pump inlet/bottom hose/bottom of radiator. You can also get away with only one connection on a pressurised

expansion tank but the coolant in the tank accumulates gunge and if you have coolant flowing through the bottle it makes topping up with

antifreeze coolant easier.

Yes, although the system hats being adapted is based on a proven design that uses a radiator with pressure cap and recovery bottle system. I should perhaps have mentioned that as they are less common these days.

I put a plain cap on the rad and made a "t" piece to fit in the top hose using a brass rad neck from Europa and a large copper plumbing "T" with the solder beads included which act as perfect barbs for the hose. It is a perfect size for my hose diameter and works an absolute treat as well as looking OEM once painted .