Anybody turboed a crossflow?

darren(SA) - 11/10/04 at 02:23 PM

Hi guys!

I was given a Garret t4 & t3 the other day and I have a spare 1600 crossflow lying around. My locost has a crossflow already.Call me mad, but I

want to play around with a spare engine. Weekend engine for a weekend car, who would of thought

I know it would be better on a toyota or any 16v but remember I do have this engine lying around.

To drop compression, could I fit the 1300 crossflow head with 1600 pistons as they both have combustion chambers? any ideas what this would drop

compression to?

thanks

darren

Volvorsport - 11/10/04 at 02:29 PM

well , youll have to check what the CR is now and determine what CR you want to run , it doesnt really matter what the CR is as long as you have good

fuel and ignition control to keep out of detonation .

A T4 might be a tad too big really for a good steet driven car , youll have to investigate flow maps and camshaft design to get the best from it -

its not just as simple as bolting it on there , youll also have extra plumbing and an intercooler to think off - IIRC someone turboed there x/flow for

a grasstracker - about 180hp.

darren(SA) - 11/10/04 at 02:36 PM

The plumbing I'm not worried about, it will be fun fabricating them! (famous last words) parts as well I can get odds and ends from a buddy,

Would I be able to run a carb (maybe 1 weber?) I know FI would be best option but it just a fun engine

thanks for quick reply

darren

JonBowden - 11/10/04 at 02:57 PM

This might interest you, the DSK was an 7 clone made in the 80s. this link shows pictures of a turbocharded crossflow installed in a seven

http://www.simplesevens.org/DSK/history/dsk13.htm

zilspeed - 11/10/04 at 04:34 PM

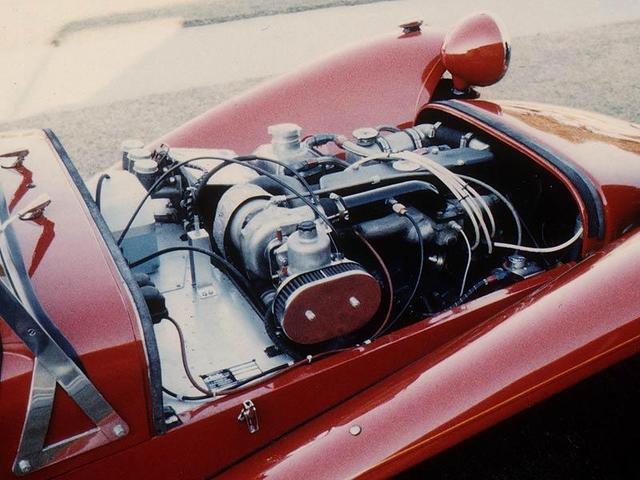

I've only ever seen B&W pics of the turbo cars in Ortenburger's book. Great use of a big old SU carb.

zilspeed - 11/10/04 at 04:37 PM

Nice use of an 1"3/4 SU

Rescued attachment dsk turbo7.JPG

GasGasGas - 11/10/04 at 04:53 PM

Try this ebay page as it lists most of the components you will need, cam dizzy etc.

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&rd=1&item=7916505645&ssPageName=STRK:MEWA:IT

darren(SA) - 13/10/04 at 07:45 PM

This is going to fun!

quote:

Try this ebay page as it lists most of the components you will need, cam dizzy etc.

went for cheap, looks like a nice little kit!

quote:

This might interest you, the DSK was an 7 clone made in the 80s. this link shows pictures of a turbocharded crossflow installed in a seven

very interesting indeed, interesting placing of the turbo due to left hand drive. Regarding the carb, doesn't the fuel get hot through the turbo?

it sure does have to pass a long way (through intercooler etc) until it gets into the head, no wonder why efi is so much more effecient!

Anybody know what the compression ratio will be with 1300 head + 1600 sub?

I've got to do some sourcing cos this does sound good

thanks

darren

gazza285 - 13/10/04 at 08:22 PM

Only the early crossflow heads had chambers and although there are many combinations that result in a higher compression, I can't think of many

that reduce it in a 1600. Find some 711M block 1600 pistons and use these with your chambered head, this should reduce the compression from the

originals 9:1, to what though, I don't know, unless somebody knows the combustion chamber volume for the early crossflow? Other pistons you could

use are the precrossflow flat top pistons, but these might lower the compression too far unless you deck the block. Again, without access to accurate

volume figures the final ratio cannot be calculated. Machining some material off the crowns of your current pistons is also a possibility, as the

crossflow has quite a distance between the crown and the first ring.

ned - 14/10/04 at 09:25 AM

you should be able to calculate the combustion chamber size. if you know the bore and stroke/capacity of the original engine and know the original

compression ratio you can calculate the combustion chamber size. eg a vauxhall 16v is approx 2000cc (500cc per cylinder) and has a cr of 10.5:1 so the

500 is 10.5 times the size of the combustion chamber. hence 500 / 10.5 gives you the combustion chamber cc. work out the figures for both spec of

engine: 711 block, 1300/1600 or whatevere and then match the cc of the engine to the relevant combustion chamber to work out the new cr.

Ned.

darren(SA) - 14/10/04 at 08:22 PM

Mmm have to check the old calculators batteries but thanks ned, should help!

but thanks ned, should help!

So in theory, for 1300 ,volume per cylinder = 1300/4 - (bore x stroke) will give me the volume(or close) of the pocket in the head, add that to my

volume of my volume of the pocket in piston(using same method) / by the volume per cylinder = cr?

I think I confused myself!

david walker - 14/10/04 at 08:45 PM

If it's a std bore 1600 X'Flow, and if the head gasket when compressed is 1mm thick and you want 8.7:1 compression (which would be about

right) then the total chamber volume needs to be 45cc.

By total chamber volume I mean the volume of the piston bowl + the volume of the head chamber.

Easiest and cheapest way to lower the compression will be to machine the top of the piston. They are easily detachable being circlip fitting and are

easy to machine in a lathe.

Best of luck with it but as has been said earlier I think you'll find the T4 a bit big.

fatfranky - 16/10/04 at 07:32 AM

I once had a similar idea but with a different engine & found a link to Ray Hall Turbocharging in Australia.

http://www.turbofast.com.au

If you go to the turbo calculators section there are all sorts of useful utilities for matching turbos to engines, flow maps etc.

For what it's worth my conclusion was to find a suitable turbo and build the engine to suit the turbo spec. I also decided that a little was

better than a lot (ie. a relatively small turbo with a moderate level of boost was more likely to work than a huge turbo running massive boost).

I also planned to use Bosch K Jetronic fuel injection, this is essentially a none mapped system that was used on early XR3i's, Golf GTI's,

Volvo's etc.

Hope this helps

darren(SA) - 16/10/04 at 10:43 PM

Over here I've heard of guys stacking head gaskets, which I wouldn't go for, and getting a thicker gasket laser cut out of copper which

I've heard works!

I think you guys are right T4 a tad big, the T3 could be ok though?

cheers darren

macspeedy - 12/11/04 at 05:32 PM

found this thought it maybe of interest

http://www.turbo-nutters.co.uk/pr_escort_mex.php