Cheers

Fred W B

[Edited on 10/4/13 by Fred W B]

[Edited on 10/4/13 by Fred W B]

Morning all.

Since I haven't finished building my new workshop yet, I find myself thinking and trying top plan bits that I have yet to do on the car. And

today's thoughts have turned to the throttle linkages. I can see a few basic ways of linking the opposing banks of ITBs, with the main two being

solid linkages and cable wheels.

Since my car is a 1969 Sprite, I don't really want the wheels there as I don't think they would look right. I know that the idea of

appearance is something of an oddity when I'm fitting a 2.5L quad cam V6, but I do still want it to look sort of right where possible. And the

wheels either need a lathe of require me to buy someone a reasonable amount of money to provide them.

The linkages though, are fairly straight forward and I can make what few bits I can't buy cheaply. Or buy cheaply assuming that RC linkages are

up to the task.

Does anyone here tinker with RC planes/car/helicopters etc? I see that there is a wide range of parts available, some metal and some plastic, but I

don't know how tough and durable such things are. If they are up to it, then the linkages are only a few quid each!

Other than that, does anyone have any ideas as to how best link opposing banks together? Is there some excellent idea I haven't thought of? Could

one bank have the throttle plates and spindles reversed so that both banks open in the same direction?

I used to work in the R?C importation industry.

if you go for balljoints on high end RC cars, especially 1/8th off road or 1/5th scale they are all tough as hell. Avoid 1/10th scale balljoints

unless you buy high end off road stuff, but they tend to be rather small (1/8th" thread or 3mm). Items from Associated, Losi, Schumacher should

be fine.

1/5th scale stuff should good quality too, although some of their metal rosejoints do wear (my preference would be steel ball/nylon rose or cup).

As for Helis, the advantage of those is that they are often rosejoints as opposed to balljoints, so have a hole in the middle for a bolt to pass

though, meaning you can fit a tapered washer under the bolt head to give a reasonable angular misalignment but in the event the joint fails (highly

unlikely...) the joint is captive with the washer so it cant pop off.

The ITBs should have a return spring in the event of cable failure anyway so if the cable/linkage failed, they snap shut.

if you can find Heim heli joints those were mega quality, zero slop, low friction and tough as old boots too.

where are you and I can maybe suggest model shops with the proverbial clue rather than one that will sell you what they have to hand ;-)

generally the aero links are a bit pants, the linkages are only rinning in a fluid (air) rather than the direct action and vibration or cars and

helis, so largely ignore R/C aircraft linkages imho

re heli linkages id go for items from a .60 size heli rather than .30-.40 size or electric as they will be beefier.

you can get some double ended balljoints (for middle ITB) as well, maybe worth looking at Sullivan or DuBro products in decent model shops (they will

have afloor mounted 'spinner stand' with hundreds of packets on).

[Edited on 10/4/13 by CNHSS1]

Look at a rover v8 carb setup for simple linkages

You just have the rod working above the spindle on one side and below on the other, you sync by adjusting the rod length.

McGill sells nice small rose joints that are just the job.

Also Claire has done all this.

Proper M5 or M6 rose joints are dirt cheap.

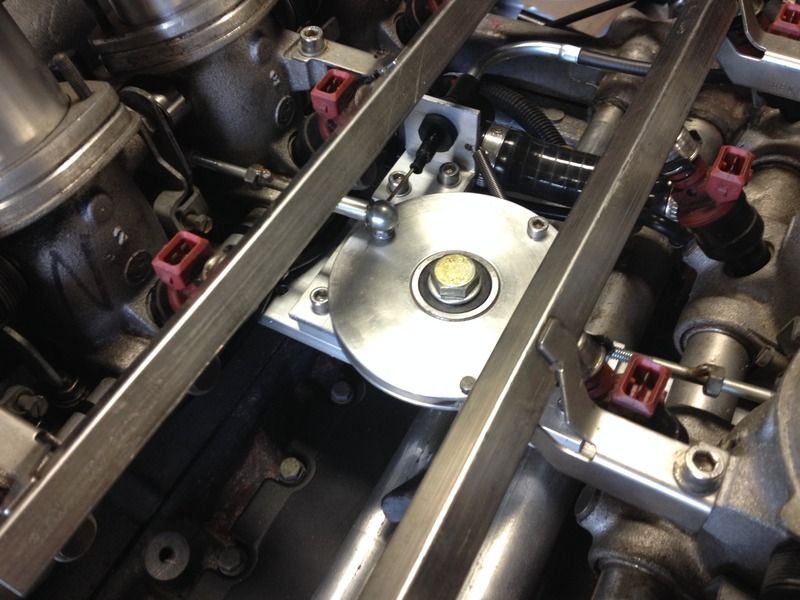

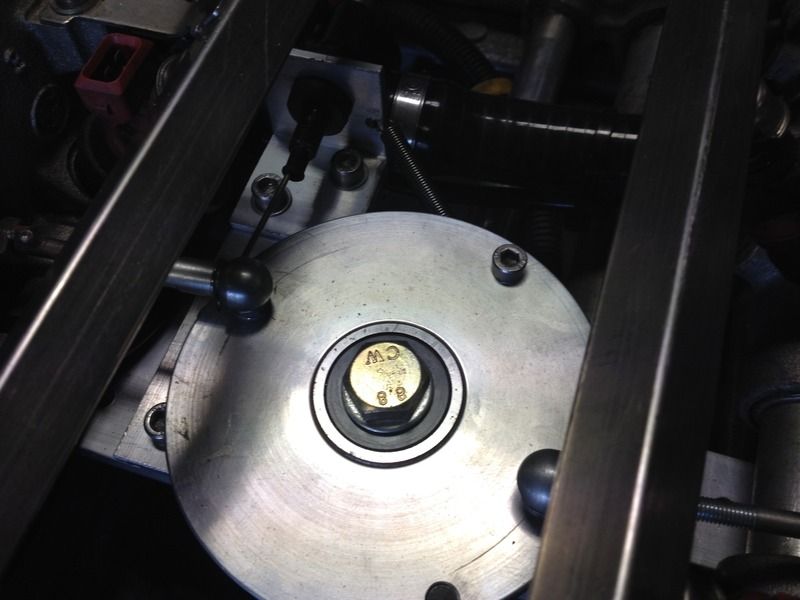

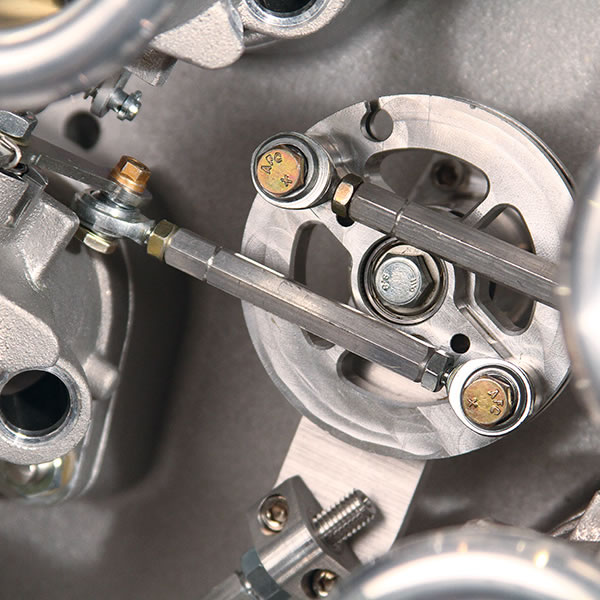

Some ideas

Cheers

Fred W B

[Edited on 10/4/13 by Fred W B]

[Edited on 10/4/13 by Fred W B]

I spent a lot of time on the linkage between banks on the V6 - and the only conclusion I came to was that it didnt work , and couldnt be made to work

.

While I did come up with a setup that worked in the open and closed position , the two banks of `bodies didnt open at the same rate - so when one side

was at say 30% open , the other set would be at 33% (or 27%....) .

Thats why I came up with the twin cable pulley setup - its the only one that works !

The only tricky part is the cable - it needs a nipple on one end , but an adjuster on the other .

[Edited on 10/4/13 by clairetoo]

quote:

Originally posted by clairetoo

I spent a lot of time on the linkage between banks on the V6 - and the only conclusion I came to was that it didnt work , and couldnt be made to work .

While I did come up with a setup that worked in the open and closed position , the two banks of `bodies didnt open at the same rate - so when one side was at say 30% open , the other set would be at 33% (or 27%....) .

Thats why I came up with the twin cable pulley setup - its the only one that works !

The only tricky part is the cable - it needs a nipple on one end , but an adjuster on the other .

[Edited on 10/4/13 by clairetoo]

quote:

I spent a lot of time on the linkage between banks on the V6 - and the only conclusion I came to was that it didnt work , and couldnt be made to work . While I did come up with a setup that worked in the open and closed position , the two banks of `bodies didnt open at the same rate - so when one side was at say 30% open , the other set would be at 33% (or 27%....) . Thats why I came up with the twin cable pulley setup - its the only one that works ! The only tricky part is the cable - it needs a nipple on one end , but an adjuster on the other .

quote:

Originally posted by coyoteboy

quote:

I spent a lot of time on the linkage between banks on the V6 - and the only conclusion I came to was that it didnt work , and couldnt be made to work . While I did come up with a setup that worked in the open and closed position , the two banks of `bodies didnt open at the same rate - so when one side was at say 30% open , the other set would be at 33% (or 27%....) . Thats why I came up with the twin cable pulley setup - its the only one that works ! The only tricky part is the cable - it needs a nipple on one end , but an adjuster on the other .

I don't understand - theres absolutely nothing I can see that stops you getting a 1:1 linkage ratio at all, other than bad design? (No offence!) In fact I'd say cable-pull was more likely to end up with problems due to play, bend, stretch inherent in the design (which is why you don't find that on any commercial options)?

Claire, what do you think of the pictures that Fred put up? Do they avoid the problems you saw or would you expect them to be similarly unbalanced at part throttle?

All those that Fred posted up have a bell-crank in the middle , and a link to each bank , as well as being in the middle of the row .

None of this is possible with the V6 - it has to go at one end , and there is just not enough didtance between the banks .

The twin pulley and cable is the way to go - after all , I copied it from Jenvey

twin SU carbs/1

Ends of gas rams are good for this kind of application  thats what i used

thats what i used

Jacko

Thanks all for the ideas and suggestions.

I'd like to avoid the cable option if I can, but making a working rod/linkage set up may be quite fiddly. But that's no real reason to not

do it.

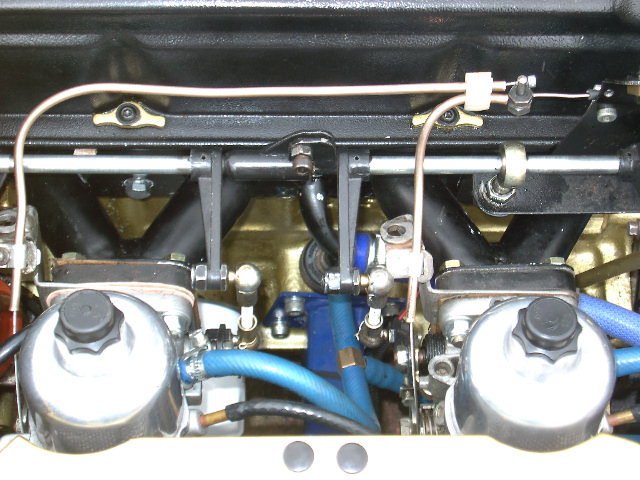

As Claire has said, there isn't normally anywhere to mount a bell crank, but I believe that could be easily sorted as this is what my current set

up looks like:

Space is admittedly not in great supply, but there is still space to run something down the middle.

The idea I had in mind was to mount a bell crank on a plate/support between the banks as per most of the V8 set ups Fred posted pics of, and then have

links going to both central bodies on extended versions of the current lever arms. This then gets round the issues as far as I can see and would

probably look something like the fourth pic of Fred's.

The other option would be to mount a rod down the centre of the whole lot and have it act directly on all 6 bodies, with adjustments being made via

the linkages. This would involve much shiny parts and look quite techy, which appeals. But it would be harder to make.

Unless there's something I'm not thinking of or not seeing? As has been said, I can't see any reason for this not allowing a 1:1

motion, but still looking as period as possible, which the cable option doesn't in my eyes.

[Edited on 12/4/13 by DIY Si]

If you go down the cable route, would the W88003 cable junction box, here do the job?

if you like shiny and techy you can get nice ballraced alloy bellcranks for model helis that would be nice and they are nice anodised colours for the extra poser points ;-)

I do like shiny and techy, but I also want to try and keep it period-ish. So I'll be using polished ally trumpets for example, rather than CF ones. But anything silver would look right, so I'll continue looking into what parts are available and go from there I think.

Has anyone got any an idea where i could get a rotating bell crank(?) like this for running ITB's on a V8?

or

Any links or help would be great!

You could easily make one if you used flanged bearings, a flat piece of ally, drill hole in the centre and flanged bearing either side, no need for machining

I'm looking at this problem myself at the moment... is there any reason you could not just use a split (1 to 2) throttle cable to drive both sets

of throttle bodies simultaneously? Or is there too much play in such a system?

Something on the lines of this:

http://www.venhill.co.uk/Downloads/U01-4-125_UniversalSplitter.pdf

Everyone seems to dislike such systems, but to be honest I can't see what the big problem is as long as the cable runs are similar lengths, although in practice that can be tricky if the banks rotate in opposite directions. Its not really any different from the old twin cable set ups, but I guess they can suffer from cable stretch? Having said that, my old Indy Bird had a massive throttle cable on it that ran all the way round the front of the chassis to give nice wide bends......

Yeah, I think I'm going to give a twin cable system a go as it's so much simpler than trying to make an alternative, and I can re-use the Hayabusa brackets. Will let you guys know how well it works!

I tried this when playing about with bike carbs on a klde. Single cable to the carbed but slit there to the two banks, pic below, not pretty but you

get the idea, may reduce stretch issues. Basically a plate with a block with one hole for the pedal cable and another block with two for the carb

cables, join in the middle with a cable clamp.

[Edited on 5/7/15 by Ugg10]

No comments have been made on gears.

A main gear in between the carbs would address counter rotation.

The only issue would be fabrication.

Gears would allow customizing pedal to Throttle opening ratio.

I have no formal engineering background so this may be a daft idea...

Or genius...

HHHH.

Hope this helps.

AA

I seem to recall using a throttle cable of an old two-stroke motorbike. It has a single cable from the twist-grip and then a splitter to operate two

cables. One for the carbotooter and the other for the oil pump. Like this:

http://www.pedparts.co.uk/product/937/piaggio-gilera-throttle-cable-splitter-block

quote:

Originally posted by Angel Acevedo

No comments have been made on gears.

A main gear in between the carbs would address counter rotation.

The only issue would be fabrication.

Gears would allow customizing pedal to Throttle opening ratio.

I have no formal engineering background so this may be a daft idea...

Or genius...

HHHH.

Hope this helps.

AA

Gears are one option I considered, but as Si has said there's manufacturing issues and it's beyond my capabilities without farming it out.

My alternate option is to mount a bearing on a plate each end and run a lay shaft down the middle with cable wheels on each end of the shaft to link

with the existing ones on the throttle bodies. The actual linkage from the pedal would then go to a third cable wheel in the middle of the lay shaft.

Simpler than it sounds, and whilst I am confident I can make it myself the twin cable set up is even simpler and hopefully easier to make!

Found this thread useful for a project I'm working on, for anyone else this may help.

Found a great supplier for Bellcranks, linkages etc etc.

Ive this all in one Bellcrank, cable holder, throttle stop, spring device with proportional throttle opening

Its on its way from Australia to me now now.

https://www.efihardware.com

This will be mounted in the V of the V8 to convert from FlybyWire to Manual cable opening.

[Edited on 28/8/15 by Benzo]