Help Identifying Pinto Bottom End, please

FuryRebuild - 14/11/12 at 12:20 PM

Dear Pinto experts out there.

I have someone interested in my engine for sale, and whilst I know the provenance of the top end and induction intimately, I don't know much

about the bottom end - never needed to; it's never given me much pain.

However, I would like to know what I have with the minimum of disturbance. Initial observations are that it's spotlessly clean inside - that

monster diet of valvoline racing oil it's had every 500 miles seem to have paid dividends.

I've taken the following pictures which have some stampings on - maybe one of the pinto aficionados here may be able to help.

Firstly, here is a picture of the entire set of big-ends. The machining in the end-caps leads me to assume it's been balanced which is very

encouraging and shows someone has cared about it:

Description

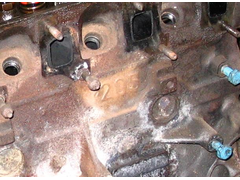

Here's one of the stampings on the big-end and a shot of the side of the big-end - it may be enough to identify if it's a V6 rod or pinto or

other. I make the rod stamping out to be SOF25S CA

Description

Description

Finally, here's the crank-stamping. I make it out to be 72 HM JA

Description

Any ideas? As ever, thanks in advance for filling in the gaps in my knowledge.

snapper - 14/11/12 at 12:47 PM

There is not much to say

Either it's a 205 block or not, big 205 or little 205 on the outside

If it was an injection engine it will have better rods, F on the flank

Big ends look standard, rod bolts are standard,crank looks standard

Not balanced

Otherwise it's a Pinto

FuryRebuild - 14/11/12 at 12:54 PM

I agree the crank doesn't look machined, but do you think my assumption that the big ends have been machined (each to a different amount) would

imply that they've been balanced? odd that they'd have been machined otherwise.

Thanks

M

chillis - 14/11/12 at 12:58 PM

Won't be V6 rods in a Pinto they have a bigger big end diameter

Crank looks to have only evidence of std balancing, No1 rod looks to be slightly different to the others

If its an injection engine then it will have 205 on the block sides, fairly obvious to see

I will check my injection rods tonight to see if that number matches up

FuryRebuild - 14/11/12 at 01:10 PM

Thanks

I can confirm it's definitely a 2 series block, not 205.

As I said, I want to be sure I'm doing the right thing by my potential buyer.

Thanks

Mark

mcerd1 - 14/11/12 at 01:17 PM

got a pic of the sides of the block ?

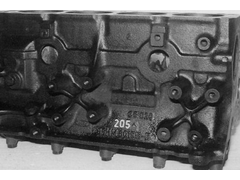

205's can look like this:

Pinto - 205 block

or this:

pinto - 205 block

snapper - 14/11/12 at 03:56 PM

There were non injection 205's

The rods will have had minimal balancing on production

To properly balance a rod you would reduce the little end then match all 4

Injection rods have an F on the side

I have put Cosworth rods on a Pinto crank then had the crank, flywheel and clutch cover balanced together

It's not pretty the way they cut into the crank webs, drill the flywheel and do stuff to the clutch cover but it runs smooth

chillis - 14/11/12 at 11:40 PM

I've checked my injection rods no markings or numbers like yours.

205 blocks were the later blocks for both injection and non-injection - they were uprated as the pre 205 block was considered not up to the job,

mainly as the tooling was well worn. New tooling so most cost effective was to use the tooling for all blocks, the 1.6L (165) and 1.8L (185) were

similarly treated.

200 blocks (the best but rarest) were cast for the RS Escort as by that time regular use of the Pinto in passenger cars had come to an end.

mcerd1 - 15/11/12 at 08:27 AM

if I get a chance at the weekend I'll dig out my spares and take some pic's

should atleast have a couple of early blocks and a couple of late ones with some rods (not sure exactly what I've got left as I've

sold/given away alot of it)

quote:

Originally posted by snapper

I have put Cosworth rods on a Pinto crank then had the crank, flywheel and clutch cover balanced together

It's not pretty the way they cut into the crank webs, drill the flywheel and do stuff to the clutch cover but it runs smooth

<<< my cossie rod in my avitar

but I got a cossie crank, its more or less the same but 9 bolt (so no extra dowels needed  ) with an offset patern so the flywheel can only go on

one way round (cossie cranks and flyweels were ballance together in the factory)

) with an offset patern so the flywheel can only go on

one way round (cossie cranks and flyweels were ballance together in the factory)

I got a steel 'pinto size' flywheel to suit and a set of forged pistons too

what they do to ballance them really isn't pretty at all (especially given the cost of some of my shinny new bits  )

)

but I'm hoping for a nice smooth free reving bottom end once its running

)

)