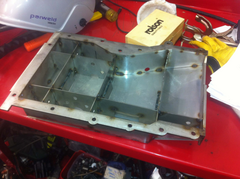

Here's the sump with the bottom tacked on, sat on the bench:

Description

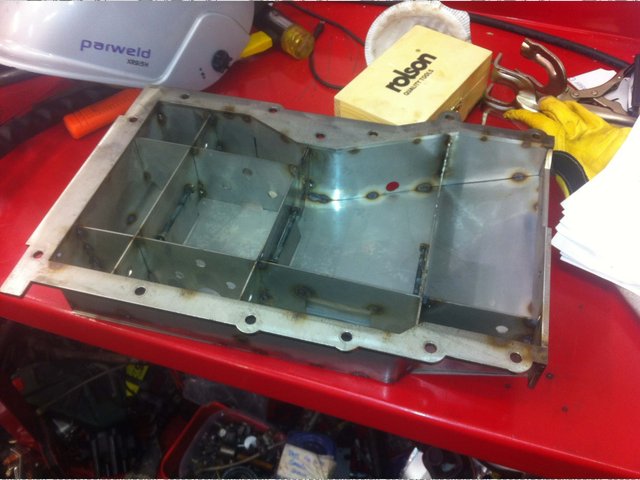

And here's an example of the welding I'm doing to hold it together:

Description

Welding stainless is great because it's easy to get the pool up, but it also warps. This weld is of a 5mm base place to a 1.5mm upright, and going thick to thin is always a challenge. I decided to go without filler (autogenous/bare back?) because I was struggling to get the neatness I wanted. This welding technique is fine for non-structural welding and especially when the two materials don't need a diluting alloy at the join (such as aluminium).

There's a small amount of undercut but again, it's not a structural joint, so I went for neatness.

In order to avoid warping as much as possible, the piece is bolted down to a 10mm lump of steel and I've only welded 1" to 1.5" at a time, allowing the piece to cool down before I move on to another part completely.

Here's hoping it's still straight when I take it off the base.