Duratec Oil Pump - disassembly

pjay - 3/5/12 at 10:16 PM

I'm currently on my second 2.0L Duratec rebuild, this time it's a 2007 Fiesta ST150 N4JB (first one was a 2001 Mondeo CJBA).

Rebuild's going well, new rings, bearings in and pistons now refitted. Now at the oil pump stage and last time I managed to pick up a

'new' oil pump from a company that had apparantly taken a crate engine and fitted a dry sump. Anyway no such luck this time so myself and a

mate thought we'd see if it's possible to disassemble and inspect an apparantly unserviceable item... (have a spare just in case anyway).

These are the photos of the oil pump disassembly so far for anyone interested:

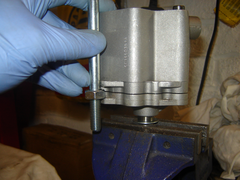

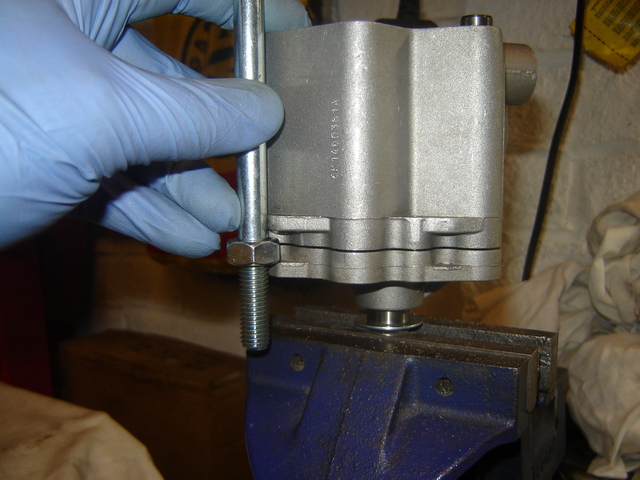

There are three locations where with care the front cover can be split from the body of the oil pump (the bolt is used carefully as a drift to tap the

front cover lose)...

Description

Description

Description

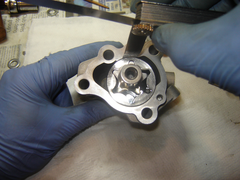

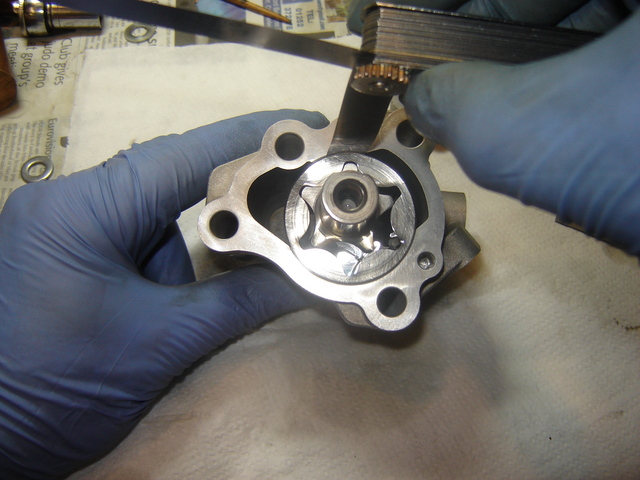

The unit disassembled:

Description

If anyone has any clearances info please shout:

Description

Anyway I'll have a go at dismantling the old CJBA oil pump (85k miles apparantly) and see what the clearances and wear are like in that.

FuryRebuild - 4/5/12 at 09:33 AM

Wow - keep up the good work.

I've just had the last of the arp bolt sets I need delivered, so am ready to start putting things back - I've left the oil pump and pistons

in the block; it's head and bottom-end this time around. I didn't want to disturb the pump if possible. no signs of wear or damage due to

starvation or over-revving when i stripped it, so I thought it was best to let sleeping dogs lie. but that's only my circumstances.

pjay - 4/5/12 at 10:44 AM

Thanks. Sounds reasonable if there's no signs of a problem. I'm planning on using the engine for IVA so I'm going for reconditioned

state and therefore full overhaul.

Interesting to note that the later oil pumps have a better machined rear surface and therefore don't have a gasket fitted (based on the three

pumps I have). If I remember I'll add the oil pump part numbers for reference.

[Edited on 4/5/12 by pjay]

FuryRebuild - 4/5/12 at 10:46 AM

I've also got a full set of crank and cam bearings as well. the nice man at sbd convinced me it was a good idea.

FuryRebuild - 4/5/12 at 10:48 AM

i'm also welding up my new sump according to flak's plans  should be a positive weekend.

should be a positive weekend.

pjay - 4/5/12 at 12:43 PM

Sounds like it should be a very good weekend for you. You mention cam bearings from SBDev - I'm not aware of cam shaft bearings or is this

something else?

In terms of part numbers here's what I have:

1) Pump from an N4JB 2007 Fiesta ST engine - 1S7G-6600-BJ

2) Pump of unknown origin (same casing as the one above) - 1S7G-6600-BJ

3) Pump from a CJBA 2001 Mondeo engine - 1S7G-6600-BD

FuryRebuild - 4/5/12 at 01:27 PM

I have a pair of Kent stage 1's to go in. I assume there's bearings in that.

I also have a main bearing set, and a big end bearing set.

I don't remember if the cams sit in bearings or just the machined surfaces. I'll have a look. Either way, camshaft bearings on this engine

aren't weak spots. Big end are with sustained high-power running, and it makes sense to replace the main set.

It's positive that the bearings and surfaces I had are in good condition, and Craig confirmed the crank surfaces when he machined it.

The parts set I've bought isn't remotely cheap, but getting it all from SBDev has meant that I have really well given expert advice, and the

compatibility is assured. Craig and SBDev are great guys.

I actually bought enough parts for two sumps, so once i've welded them, I'll put one out on ebay unless a member here wants it. they're

in 304 stainless.

pjay - 4/5/12 at 03:47 PM

On the Duratec there aren't any replaceable cam shaft bearings - as you say they run in machined surfaces in the head and in the caps.

It's good you got the crank checked. What are SBDev's instructions on position the main and BE bearing shells since there aren't any

locating tabs and I've just been through the instruction in the assembly chart... A lot of vernier caliper work to position the shells!

I'm using a Raceline sump but I might know someone who could be interested in a sump - what sort of money were looking for?

FuryRebuild - 4/5/12 at 04:40 PM

I'm not sure yet, as far as costs go. If I could get £200 for a sump I'd be happy bearing in mind the following:

1) £80 for the stainless to be cut

2) argon for tig welding

3) approx 6-8 hours to make a sump

4) sump plug and dipstick to be sourced and fitted.

5) 10mm solid steel jig to bolt the mating flange to avoid warping.

Once I've made my first, I'll have a better idea. If you look at the welded ones for mk2 escorts, they're about £350, as are the cast

ally ones.

flak monkey - 4/5/12 at 06:36 PM

The main and rod bearing shells will go straight in, you dont need to faff about measuring them all with a micrometer. Just check with some

plastigauge. All mine were spot on when fitted.

As for the oil pump, if it doesnt have any scoring, or excessive clearance (0.1-0.2mm is the normal sort of range) then it'll be fine as well.

They are only unserviceable because you cant buy the seperate parts for them.

pjay - 5/5/12 at 08:45 PM

quote:

Originally posted by flak monkey

The main and rod bearing shells will go straight in, you dont need to faff about measuring them all with a micrometer. Just check with some

plastigauge. All mine were spot on when fitted.

Plastigauge - I'm not talking about the bearing clearance e.g. between the shell and the journal. It's getting the two halves of the bearing

shells to be reasonably aligned laterally. There's scope to get them misaligned by a mm or two since there aren't locating tabs like on the

Pint. Significant misalignment can't be good for journal and bearing wear.

The assembly chart has a lot of info on this but I'm interested to know what SBDev have said about replacing the shells... FuryRebuild?

Anyway clearance info from the 2007 N4JB pump (as close as I can get anyway):

Outer rotor to body - 0.063mm

Inner rotor to outer rotor - 0.063mm

Rotor endfloat - 0.076mm

In comparison the Pint shows in the Sierra Haynes manual as:

Outer rotor to body - 0.153 to 0.304mm

Inner rotor to outer body - 0.050 to 0.200mm

Rotor endfloat - 0.039 to 0.104mm

Differences between the two pumps are quite significant but my figures look okay. I'll see what I get from the higher mileage CJBA pump.

flak monkey - 6/5/12 at 06:30 PM

Oh yes I remember what you are talking about now. Just line them up as best you can with the parts disassembled, then assemble them without knocking

the bearings out of position. If that makes sense

Your oil pump will be fine I am sure.

should be a positive weekend.

should be a positive weekend.