Cooling.....I know, Again! :)

Daddylonglegs - 13/3/12 at 05:22 PM

I am having some issues with my cooling for the 2.0 Pinto. I have searched much on the forum and after looking at many options, I think mine is wrong.

I have fitted a CBS adjustable 'in-hose' thermostatic control for the electric fan, and have fitted a matching guage and sender for the

water temp. I have the fan set to come on at around 80deg at the moment because the temp was going up to just over 100deg and looked like it was still

slowly climbing  . So I set the fan to come on before it reached that temp.

. So I set the fan to come on before it reached that temp.

Problem is, I don't think that the fan is really doing a deal even though it is sucking air through the rad nicely. I have a feeling that there

is not enough water going through the top hose to trigger the fan and it also feels as if there is more air than water in the upper hose. I tried

running with the cap off to bleed some air out but I think my fundamental setup is wrong.

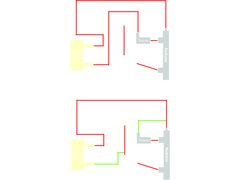

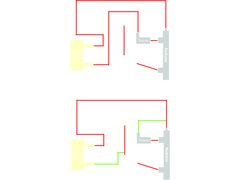

The 2 pics below show the system as it is now and how I think it should be.

Cooling

Any input welcome guys

John

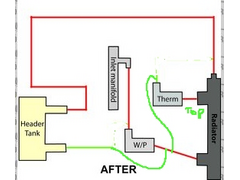

Pictures of the offending article:

Cooling1

Cooling3

[Edited on 13/3/12 by Daddylonglegs]

loggyboy - 13/3/12 at 05:24 PM

Diagram isnt that clear about pipe diameters from header, and which is top of rad etc.

loggyboy - 13/3/12 at 05:31 PM

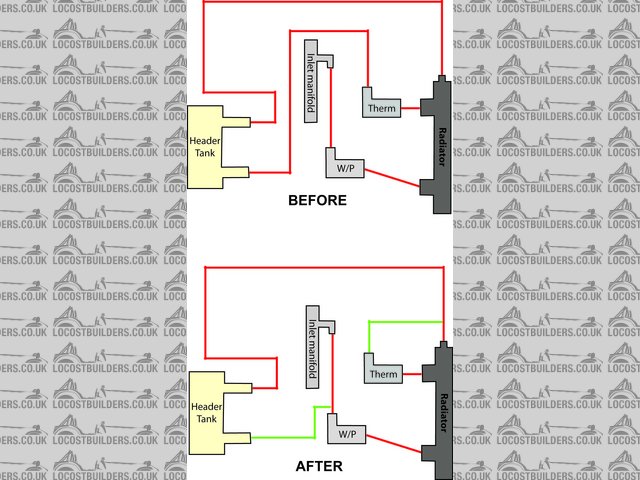

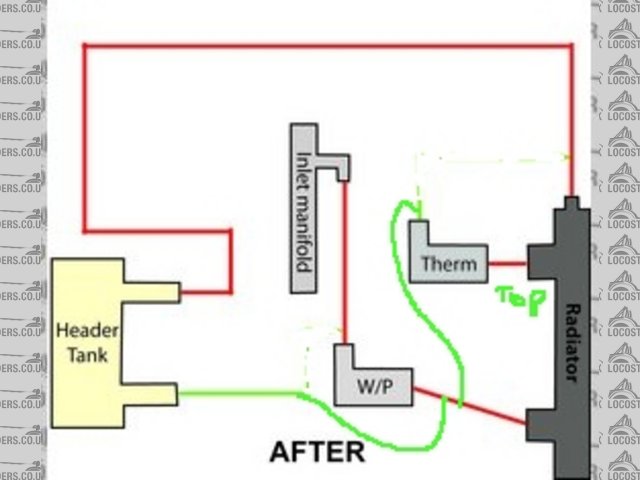

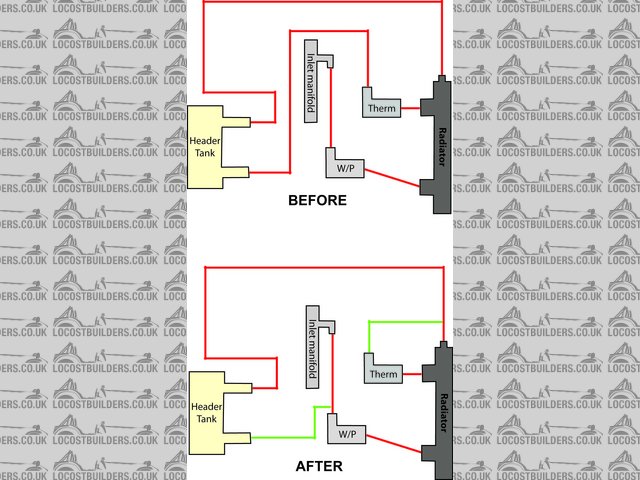

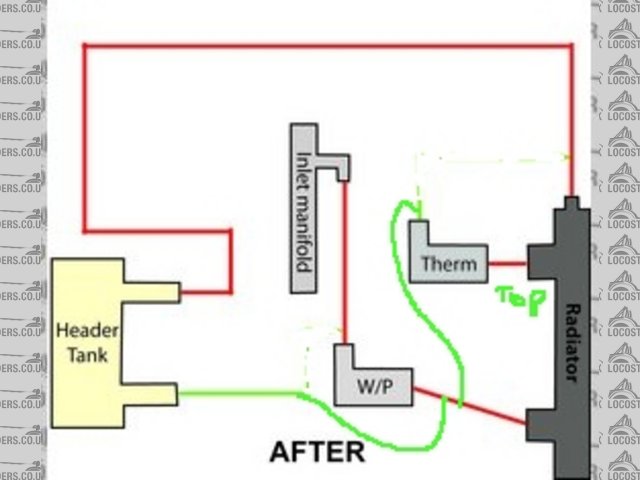

here is how I would do it:

PintoPlumbSuggestion

MkIndy7 - 13/3/12 at 05:39 PM

Is there not a bypass hose missing from that?

We had the connections that would have gone to the heater matrix or inlet manifold looped so there was always some flow in the system when the

thermostat was closed.

Can't for the life of me picture or remember where it would go in the diagrams above, but if you could find the original sierra setup somewhere

i'm sure all would be revealed.

Daddylonglegs - 13/3/12 at 05:44 PM

Sorry

Radiator and Header are 'correct' way up, i.e top is top etc. Radiator has small connection on top opposite side to upper large hose. bottom

hose is also the large (about 50mm IIRC).

I have added a couple of pictures of the actual car to help.

snapper - 13/3/12 at 06:07 PM

Biggest difference on my Pinto was fitting an 82 degree thermostat from Burton performance.

The standard one opens at 88 degrees

You can modify and fit a mini 76 degree one

Also drill a 4mm hole in the thermostat to let air and a little water flow through.

I also fitted a bleed T in the 16mm hose from manifold to water pump

[Edited on 13/3/12 by snapper]

jollygreengiant - 13/3/12 at 06:15 PM

I run a 2.0 pinto and have NO cooling issues whatever. This subject HAS been dealt with previously and I have copied it below as per my post on the

subject

Copied bit -------

I tried it like you have posted and it gave me problems so this is what I ended up with

Rad lower to water pump - YES

Rad Upper to thermostat - YES

Water pump small to ( bottom of header tank - NO ) Goes to small on inlet manifold.

Inlet Manifold to ( top of header tank - NO ) Goes to small water pump.

Small thermostat port ( blanked off. - NO ) bleed pipe from top hose goes to top header tank/bottle collecting Via a 'T' piece the bleed off

the top of the thermostat return to top of header tank/bottle.

Bottom of header tank/bottle should go to a 'T' piece cut/spliced into bottom hose.

Also, IF you have a bleed pipe on the top of the radiator, then this should be 'T'ed into the bleed pipe off the top of the thermostat.

-----------------End copied.

the link to the post is as below

Linky dinky to PINTO COOLING.

Basically both of your cooling layouts are wrong and will give inherent problems with fill/cooling/operation.

Dopdog - 13/3/12 at 07:06 PM

I'm a bit confused? if this was fitted into an escort with twin carbs on you could just blank off the heater pipes and run the engine on just the

top and bottom hose as the radiator would be filled up from the top.

OK our cars can not do this so we need to fit a header tank, why can you not have the bottom connection from the header tank tee pieced in to the

bottom hose (this is how you fill the system from the lowest point). You then use the small air bleed from the top of the rad as a return to the

header.

If you are using a heater then plum it in as well, also if you wanted to you could use the small bleed off the thermostat housing to back to the

header.

Dopdog - 13/3/12 at 07:08 PM

Just read this again and I have said the same as the Jolly green giant

Dopdog - 13/3/12 at 07:10 PM

Last one for you, caterham used to do a bit for the water system call a submarine. It was a straight tube with a small takeoff that went to the

header.

simples

[Edited on 13/3/12 by Dopdog]

davidimurray - 13/3/12 at 10:06 PM

As per Jollygreengiants link to my post I setup my Pinto as reccomended and it made the world of difference. Much easier to bleed and lowered the temp

at which fan kicked in.

martinq357 - 13/3/12 at 11:32 PM

This is my set up with a Polo Rad....

- 82deg stat(with a 2mm hole drilled in the face to allow bleed through during warm up and also making sure the drilled hole is at the top when

locating the stat in the housing) and a 88deg On - 78deg(i think) Off thermal switch in the rad.

- Top hose from stat housing to the top of the rad.

- Bottom hose back to the water pump, Tee'd off to the bottom of the header tank.

- No heater so the smaller pipe at the water pump blocked off.

- The inlet manifold pipe is also blocked off but I have fitted a central heating bleed valve to help bleed air out during initial filling.

- Small pipe from the top of the rad back to the small pipe on the header tank.

It's really straight forward to fill & bleed now and have never had an overheating problem....... famous last words...

HTH,

Martin.

britishtrident - 14/3/12 at 08:43 AM

There are a few ways of connecting but the really important thing is to get the coolant circulating even when the thermostat is closed.

This is for several reasons first of all the thermostat will not work properly unless hot coolant can get to and around the thermostat bulb even

when the engine is cold and the thermostat closed and to allow coolant to circulate between and within the head and cylinder block to avoid the

formation of hot and cold spots within the engine.

Pinto thermostat housings differ in design if the thermostat housing has a small diameter outlet or outlets this should be connected back to a

water pump inlet or the bottom hose, this can be via a header tank ie into top of the header tank and bottom of header tank connected to the

bottom hose via a tee.

The main by-pass for circulating coolant should come from the outlet for the heater on the head back to the water pump.

A small hole drilled in the thermostat will aid bleeding the system and provide an extra by-pass flow that will make the thermostat respond

faster, however if you have too many/too large holes it will make the coolant take a longer time to warm up.

If you don't have a small bore by-pass connection on the thermostat housing multiple holes in the thermostat will allow the thermostat

to work properly BUT it wif this is the only by-pass flow it won't provide enough circulation within the engine to avoid hot and cold spots

forming in the block and head.

The job of the electric fan is to control the radiator temperature not the engine temperature, it should be ideally fitted either in the radiator,

both the fan switch on and off temperature should be above the thermostat start to open temperature.

Daddylonglegs - 14/3/12 at 09:25 AM

OK, thanks for all the input guys.

So, from what I can tell, (if I got this right), the only difference between Jolly's and Martin's is that Martin has no connection between

the manifold and pump top connector, only a bleed in the manifold and blocked at the pump?

(Martin, I assume you have the large connection from the Thermostat housing to the radiator top hose and the small connection on the stat housing to

the radiator bleed (small) connection on top?)

If I got it right, I just need to change mine so the bottom hose from exapnsion tank to stat small needs to be changed to a 'T' in the lower

rad hose, and the small stat connection 'T'eed into the ET top hose to radiator small bleed connection?

God! how can a simple cooling system be so damn difficult to understand??

JB

britishtrident - 14/3/12 at 06:15 PM

Sounds good to me.

Daddylonglegs - 14/3/12 at 07:29 PM

Well, managed to get a 'T' into the bottom rad hose and connected up as above. I need to get a 'T' for the top connector to rad

small bleed connector and stat small connector. At the moment, I just left the small rad bleed open and ran the car until it started spitting water

out of there then just closed it off with a stub. Seems to be working fairly well, engine temp gets to about 95deg on gauge, fan cuts in at about same

(set for 85deg), cuts out when temp drops to about 90deg

That's the good news, but the bad news is....

......the damn fan has started making a real squealing noise! I think it's one of those brushless type and the rotor has come away

Now got to sort out another damn fan, more cash

Dopdog - 15/3/12 at 07:33 AM

bin the fan on the motor and get an electric one.

Daddylonglegs - 15/3/12 at 07:59 AM

quote:

Originally posted by Dopdog

bin the fan on the motor and get an electric one.

It is an electric one mate, motor's packed up!

Dopdog - 16/3/12 at 05:37 PM

I will just keep quite then

. So I set the fan to come on before it reached that temp.

. So I set the fan to come on before it reached that temp.