Good advice

I bought my bellhousing second hand from a member of the tiger forum and thankfully it already has a mod to suit this

Bellhousing

Hi,

Now that it seems that quite a few are installing Duratecs along with type 9 gearboxes I though it worth dragging up this topic from the past as a

heads up.

http://www.locostbuilders.co.uk/viewthread.php?tid=44227

Cheers,

Colin

Thanks Colin

Good advice

I bought my bellhousing second hand from a member of the tiger forum and thankfully it already has a mod to suit this

Bellhousing

Does this depend on whether you have the hydrolic or cable clutch bellhousing? I have the cable type and I not sure whether it is the same. Mines the

RWD version.

Not really clued up on these things so not sure what this all means

This is mine:

[Edited on 24/8/11 by Tiger Super Six]

Is this particular to Quaife or both Quaife and the Ford type 9?

Just fitted my engine sounds like it needs to come out again?

I am a bit condused here.

the bit that I think is "circled" in the earlier thread is part of the gearbox that is meant to move in and out as you change gear.

Certainly this is what I noticed when having a play with mine.

The casting of the Bellhousing has a "cutout" in it to allow this small shaft to move in and and out as necessary. I think the problem is

that that some very early Duratec castings didnt have the cutout, meaning the shaft was not able to move in and out as required when changing gear.

I stand to be corrected but it certainly looked to me that the bellhousing had this cutout "built into" the design to allow this shaft to

move in and out.

The best picture i have is below - it shows the bellhousing from the inside. The "cutout" on the bellhousing can be seen to the left of the

main shaft hole that goes through the centre of the housing. This is what the gearbox "shaft" would move into when changing gear.

Description

But, hey what do I know

That was also my understanding and it does go in and out when you select the gears. I was assuming it was a problem on some where there is a hole

there but nothing to stop it going further (if that's what the original poster meant).

Your picture, like mine, shows the recess for it to move into but it is inset and closed so the shaft can't come too far out - well that's

what I assume!

Not really sure other than that what the problem is?

Sim if you look at the picture again you will see the shaft you reffer too directly opposite just behind the input shaft.

But I cant say I remember seeing the one this thread reffers to

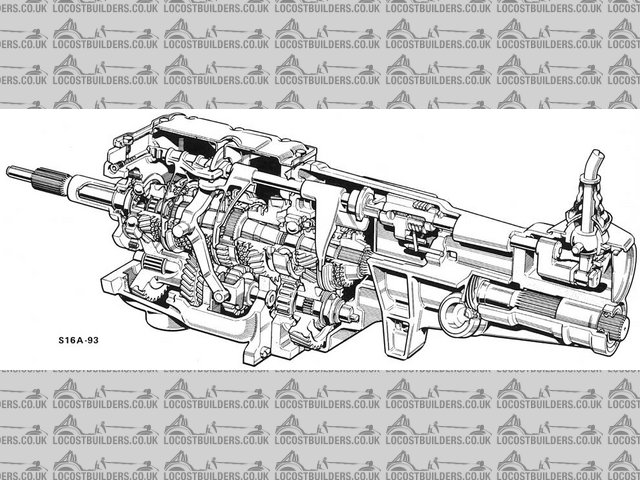

Looking at the diagram below the lay shaft shouldnt be able to move forward because there is a shoulder at the opposite end, however I can see how it

may be prone to leaking oil as there will not be anything holding the gasket against the shaft end

[img]

Type 9

[/img]

quote:

The recess in the bellhousing is to cater for the heavy duty Type 9 boxes. The layshaft on these is supported by a larger roller bearing and the housing for this protudes from the front of the gearbox housing.

Looking at another picture of mine it appears to have a bolt in there (bottom right hand corner (ish) of the pic, black stud you can see) which I

assume stops the movement?

This compares to another pic (se7ensports I think) that shows the hole with nothing in?

RWD Bellhousing

RWD Bellhousing

[Edited on 24/8/11 by Tiger Super Six]

[Edited on 24/8/11 by Tiger Super Six]

[Edited on 24/8/11 by Tiger Super Six]

You are looking in the wrong place the center photograph shows a cavity at 6 oclock it is in that cavity that the shaft lies therefore nothing is stopping the shaft move towards the engine.

That cavity and black stud is at 6 o'clock (not quite as the picture is at a slight angle) - the cut out in the bellhousing in my pic is for the

clutch release arm (I'm not using hydrolic) not the starter motor if that's where you were taking the orientation from.

The bellhousing sits pretty much as it is in that picture, with the clutch release arm coming out at 7 o'clock in reality, but appear about 8

o'clock in that pic.

[Edited on 24/8/11 by Tiger Super Six]

Why is nothing I do straight forward!!!!

So that's a mod to the bellhousing. I'm just pleased I haven't fitted it yet!!

Neil

Hi,

The item circled in the thread I referred to is the layshaft which doesn't move in and out when changing gear.

On the old cast iron pinto bellhousing the casting was flush around this area so prevented movement.

The layshaft has a 9-10mm long tang at the other (inside) end to prevent it from rotating, so if it moves forward by this distance it will cause

serious problems. The layshaft doesn't have other means of holding it in at the input shaft end.

By some of the photos it looks like the issue is known and been addressed by some, but there my be some that are using the non hd gearbox with the

recess in the bellhousing unfilled.

I was using a quaife hd gearbox.

HTH

Basically what CairB says. The layshaft needs retaining in the gearbox somehow. Whether its with a spacer/wedge, plate or whatever it needs to be held in there somehow or it will find it's way out eventually.

Engine back out then, thanks for your comment David

I just checked mine and there is a bolt in there (head on the gearbox side so you just feel thread coming through), so I assume that's there to

stop the problem? It sits slightly higher than the horizontal line made across the 2 bottom securing bolts (that hold bellhousing to the gearbox).

Does that sound right? Don't want the engine out ideally!!

[Edited on 24/8/11 by Tiger Super Six]

TTS you are looking in the wrong place you cannot see the pocket which needs filling/packing when the bellhousing is fitted to the gearbox.

Look at the first picture posted by redeye, you will see a hexagonal piece of alluminium located in the cavity/pocket in question. The hexagonal piece

will press against he end of the layshaft.

I think like me you will need to take out the engine and make up a packing peice similar to redeye's

That is exactly where I am looking. I have a bolt going through from inside the pocket so I can feel the thread coming through the other side. I

assume that it is in there so that the head of the bolt (which I can't see) stops the problem occuring?

[Edited on 24/8/11 by Tiger Super Six]

Mark

If you look at the Tiger forum pete (pjay) the Tiger forum Who I believe you a familiar with has the same bellhousing as you.

he also shows some pics of his bellhousing which apears to have a bolt in the hole you're talking about

Im not sure if you purchased them from the same place but It may be worth asking him if the bolt was there when he bought it.

http://viatron.websitetoolbox.com/file?id=1037152

http://viatron.websitetoolbox.com/file?id=1038998

Hi,

Yes, we both got them from RWD motorsport and the bolt came already in the hole, as with mine. I am 99.9% that mine is OK. RWD are on holiday until

next week but I will call them to make sure when they are back.

quote:

Originally posted by Tiger Super Six

Looking at another picture of mine it appears to have a bolt in there (bottom right hand corner (ish) of the pic, black stud you can see) which I assume stops the movement?

This compares to another pic (se7ensports I think) that shows the hole with nothing in?

RWD Bellhousing

RWD Bellhousing

[Edited on 24/8/11 by Tiger Super Six]

[Edited on 24/8/11 by Tiger Super Six]

[Edited on 24/8/11 by Tiger Super Six]

I've written to Titan to ask them why they don't make people aware and that they may be causing issues for people doing conversions no reply

as yet.

My Engine is coming out this weekend too!!

quote:

Big thanks to Claire for pointing this flaw out, would have been good if RWDmotorsport had...

quote:

Originally posted by redeye

quote:

Big thanks to Claire for pointing this flaw out, would have been good if RWDmotorsport had...

Erm.....do you mean Colin?

Sorry, but I really think that this "hole" going all the way through the Bellhousing is a red herring. When mated up to the Type9 I could

not see how this would in anyway interfere with any part of the gearbox. As mentioned the only part of the gearbox that moves is the "small

shaft" that moves freely into the pre-drilled(machined) hole on the back of the bellhousing.

I cant even see why the "hole" that goes through the BH would need to be blocked (with a bolt etc), because from what I coudl tell, even

with the gasket in place there was not a tight dirt seal around the back on the BH and the bearbox.

It could be I have a different type of gearbox although it is a type9.

I do know that these bellhousings have multiple applications and remember being told that they can be used in a Morgan, which is perhaps why it has

certain other fixings and moulding options.

annoyingly I would have taken pictures to show all this at the time, but had just hurt my back so could hardly move - Two weeks of Diazapam

(Spelling) and rest has just about sorted me out

Hey karlak, its not the 10mm hole thats the problem, it is the 3inch wide and 1inch deep recess on the lower half of the bellhousing that does not

exist on the standard type 9 bellhousing which will allow the layshaft to drift out.

[Edited on 27/8/11 by se7ensport]

quote:

Originally posted by se7ensport

Hey karlak, its not the 10mm hole thats the problem, it is the 3inch wide and 1inch deep recess on the lower half of the bellhousing that does not exist on the standard type 9 bellhousing which will allow the layshaft to drift out.

[Edited on 27/8/11 by se7ensport]

quote:

Originally posted by karlak

Sorry, but I really think that this "hole" going all the way through the bellhousing is a red herring. When mated up to the Type9 I could not see how this would in anyway interfere with any part of the gearbox. As mentioned the only part of the gearbox that moves is the "small shaft" that moves freely into the pre-drilled(machined) hole on the back of the bellhousing.

quote:

Originally posted by MikeRJ

quote:

Originally posted by karlak

Sorry, but I really think that this "hole" going all the way through the bellhousing is a red herring. When mated up to the Type9 I could not see how this would in anyway interfere with any part of the gearbox. As mentioned the only part of the gearbox that moves is the "small shaft" that moves freely into the pre-drilled(machined) hole on the back of the bellhousing.

You are correct in that this is the only shaft that should be moving. The problem which this thread refers to is the shaft which is near the bottom the face that bolts onto the bellhousing. This is the layshaft, and absolutely should not be allowed to move out at all. It is prevented from doing so by the standard Ford bellhousing, but the Duratec bellhousings are designed for the heavy duty type 9 that have a large bearing housing in this position, so the bellhousing has a recess to clear this. When used with a standard type 9, this recess allows the layshaft to move out with potentially disastrous consequences.

quote:

Originally posted by MikeRJ

quote:

Originally posted by karlak

Sorry, but I really think that this "hole" going all the way through the bellhousing is a red herring. When mated up to the Type9 I could not see how this would in anyway interfere with any part of the gearbox. As mentioned the only part of the gearbox that moves is the "small shaft" that moves freely into the pre-drilled(machined) hole on the back of the bellhousing.

You are correct in that this is the only shaft that should be moving. The problem which this thread refers to is the shaft which is near the bottom the face that bolts onto the bellhousing. This is the layshaft, and absolutely should not be allowed to move out at all. It is prevented from doing so by the standard Ford bellhousing, but the Duratec bellhousings are designed for the heavy duty type 9 that have a large bearing housing in this position, so the bellhousing has a recess to clear this. When used with a standard type 9, this recess allows the layshaft to move out with potentially disastrous consequences.

Engine taken out this morning engine gearbox and Bell all split up.

Just waiting for my big drill to recharge and I will and tap a 10mm thread and fit a 10mm bolt to retain the lay-shaft.

Get it all back together this afternoon and back in tomorrow  .

.

Despite the PITA, I would like to thank the forum raising this issue, as I see it, this as a massive safety issue that perhaps needs posting in a more

permanent position somewhere as I had never heard of this issue and If I had have missed this post would never had done anything about it.

Can't imagine the damage that could be done at 70mph if the lay-shaft drops out.

quote:

Originally posted by big-vee-twin

Engine taken out this morning engine gearbox and Bell all split up.

Just waiting for my big drill to recharge and I will and tap a 10mm thread and fit a 10mm bolt to retain the lay-shaft.

Get it all back together this afternoon and back in tomorrow.

Despite the PITA, I would like to thank the forum raising this issue, as I see it, this as a massive safety issue that perhaps needs posting in a more permanent position somewhere as I had never heard of this issue and If I had have missed this post would never had done anything about it.

Can't imagine the damage that could be done at 70mph if the lay-shaft drops out.

quote:

Originally posted by big-vee-twin

Engine taken out this morning engine gearbox and Bell all split up.

Just waiting for my big drill to recharge and I will and tap a 10mm thread and fit a 10mm bolt to retain the lay-shaft.

Get it all back together this afternoon and back in tomorrow.

Despite the PITA, I would like to thank the forum raising this issue, as I see it, this as a massive safety issue that perhaps needs posting in a more permanent position somewhere as I had never heard of this issue and If I had have missed this post would never had done anything about it.

Can't imagine the damage that could be done at 70mph if the lay-shaft drops out.

My Bell housing didn't have a hole in it, so I marked out and drilled and tapped a 10mm thread and inserted a10mm bolt fitted with spacers made

up from a nut and washer so it sat level with the machined face as below.

I then put a blob of grease on the end and married the bell and box together to make sure it was touching the lay-shaft end, which it did.

I wouls say if you have a bolt in the same place as the one I have just fitted today then your probably ok.

[img]

Layshaft retaining bolt

[/img]

Thanks for the reply and it looks like I am a lucky one!

quote:

Originally posted by redeye

Mark

If you look at the Tiger forum pete (pjay) the Tiger forum Who I believe you a familiar with has the same bellhousing as you.

he also shows some pics of his bellhousing which apears to have a bolt in the hole you're talking about

Im not sure if you purchased them from the same place but It may be worth asking him if the bolt was there when he bought it.

http://viatron.websitetoolbox.com/file?id=1037152

http://viatron.websitetoolbox.com/file?id=1038998

Pete,

But if you read the blurb on the page you quote it does say "Supplied with a recess machined in the gearbox end of the bellhousing to accommodate

the layshaft boss found on some heavy duty Type 9 gearboxes. Fitted with layshaft retaining cap screw in cases where this recess is not

needed"

So it would appear we are OK!!

[Edited on 30/8/11 by Tiger Super Six]

Hi Mark - this is all ringing a bell again (have to bear with me its been a year since I was doing this part of the conversion!). I can now remember a discussion with Ian at RWD and he explained this issue but said the bolt would come with the bellhousing! RWD to be commended.

Ummmm, just read through this and became increasingly concerned toward the end, but it would appear RWD Motorsport have addressed the issue so we

should be ok? Bit paranoid now, dont think I even took any pictures of our bellhousing prior to fitting......

Duratec's been in about 18 months now, 3 trackdays and probably 5000 miles road use. I'd say the BH is 2 years old - might give them a ring

and see when they started installing the bolt? Dont really fancy pulling it all out.

This thread highlights that there's a fair few Duratec conversions done or WIP, good to see.

If you put your hand inside the bellhousing (I assume you have the cable clutch) you can feel if the bolt is in there as part of it will be coming

through to the inside. I had a picture of mine, but still thought I would check

I spoke to RWD today; they were very apologetic about the mistake and have put a new bolt and spacing in the post, apparently all bellhousings are supposed to have the spacer included.