Weird idle problem

flak monkey - 19/5/10 at 05:24 PM

Took the car down to Atspeed in Essex on monday and now runs like a dream other than a minor idling problem which is a little irritating! This is by

no means their fault, I was well aware of it when I left and I knew it was something I was going to have to play around with.

Been playing around with the cold start tonight as we couldnt do this on the dyno. Seems to start and run fine when cold, didnt need much adjustment.

Will continue to play around tomorrow.

I cannot get it to idle properly when hot though. If you leave it idling for any length of time it will go from being too rich (12afr) to too lean

(18-20afr). If you keep it running and dont adjust anything it goes between the 2 about every 2 mins or so. When running rich it idles nice and smooth

+/-50rpm from target with no spark correction. Once it goes lean however it runs too slow, lumpy, misses and whacks in loads of spark correction as

you would expect from running so slow. After a while it usually stalls and then is a pig to restart as it continues to run lean once restarted.

I tried opening the throttle a little with the stop and then bringing the speed back down with ignition and it didnt seem to help. Also tried closing

it a little, and again it didnt help.

I had a hunt around all the corrections and didnt find anything which could affect it. Basically air temp and coolant temp corrections are all zero

when it plays up.

Any suggestions would be greatly appreciated! I have also been in touch with Colin at Atspeed and Andy at Omex. Colin saw the same problems on the

dyno on monday.

Any ideas?

maartenromijn - 19/5/10 at 05:35 PM

What engine do you have?

This might help you out: http://www.btinternet.com/~madmole/Reference/Idle.html

flak monkey - 19/5/10 at 05:46 PM

Its a duratec

The one thin that has made me think from that link is the crankcase breather...

Its not attached to anything at the moment and I wonder if there is a valve in there somewhere....

Off to have a look if I can get to it!

flak monkey - 19/5/10 at 06:48 PM

Well, and I say this cautiously, that seems to have helped.

What I thought was just an elbow in the breather was actually a PCV. Removed its internals now so it can breathe properly.

So its been running all this time with no crankcase ventilation. Oops!

It does seem to have helped and hopefully now I can get my idle tuned up properly when its cooled down again tomorrow (everything gettin rather

warm)

Thanks for the inspiration!

MikeRJ - 19/5/10 at 07:16 PM

Another thing to beware of is electric cooling fans cutting in and out and pulling the system voltage up and down. If the voltage compensation in the

ECU isn't set correctly this makes quite a difference to fuel delivery at idle when you have narrow injector pulse widths.

robocog - 19/5/10 at 08:53 PM

Heat soak on the air temp sender?

I guess easily monitored with a laptop and can of freeze spray at the ready

I know MS as std does overcompensate air temps and last REALLY hot day we had I was co-incidentally driving back from somehere and things got pretty

thin and weak and noticed a certain ammount of "surging" till speeds picked up and the temp sender saw some vaguely cooler moving air

Mounted sensor in a rubber tube to try and isolate it and keep it well away from the ally backplate and did get some exhaust wrap, but not fitted that

yet

I won't know if its helped untill we get another summer ;-)

Is your sensor into a chunk of ally that could be getting heat soaked?

I know you have ditched MS and gone over to the side with telephone support but still worth checking

Regards

Rob

austin man - 19/5/10 at 09:41 PM

do you have an air bleed into the inlet manifold ?

Just had to do this on the 2litre zetec turbo ticks over briliantly now. also had to fit one into a standard injected zetec

flak monkey - 20/5/10 at 06:56 AM

Took the car for a run ths morning and its definately still playing up once its hot.

Very difficult to restart and keep running reading 18-20AFR on the dash at idle.

The air temp correction doesnt cut in until MAT of 60deg as it was causing other problems.

It could be something to do with the battery voltage compensation I guess. Once its properly hot the fan runs permanently (on at 88 and off at 82) so

it could be that.

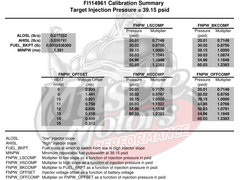

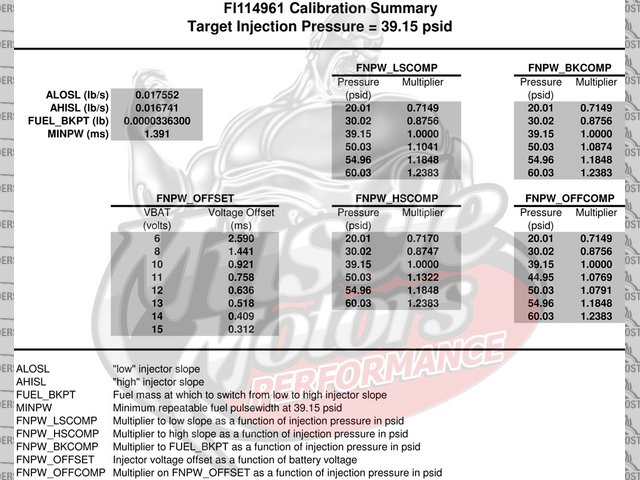

Annoyingly I cannot find any battery voltage correction data for the Siemens Deka IV injectors I have fitted.

atspeed racing - 20/5/10 at 07:24 AM

I think as we have both checked everything that could effect the mixture, perhaps you should have the induction system checked for leaks with an evac

smoke tester. This will find any leak in the induction system in minutes.

there must be a local garage somewhere near to you that would be able to do this, if you cant find anyone, drive down to us on Saturday and we will do

it for you straight away.

I dont think this is a software problem.

Alan

flak monkey - 20/5/10 at 07:32 AM

Thanks for that - I'll have a hunt around tonight and see if I can find any leaks anywhere.

Could it be the injector battery compensation?

The current values in the map are:

10v 119

11v 96

12v 78

13v 65

14v 54

15v 45

And from what i can find on the interweb the correct values for my siemens dekas are:

10v 92

11v 76

12v 64

13v 52

14v 41

15v 31

Which are considerably lower? I would have thought this would tend to make it rich though?

Deka spec sheet

[Edited on 20/5/10 by flak monkey]

atspeed racing - 20/5/10 at 08:22 AM

Dont get to complicated. Always start at the start!

We have never had this problem before and when you concider the amount of cars we do!

Get the induction system EVAC tested first as this will find any leak. You might be suprised just how many leaks you have.

flak monkey - 20/5/10 at 08:32 AM

Ok will do.

There is only 1 joint between the butterfly and the valve and thats where the throttle bodies meet the head. Will check everything is tight tonight

and go from there.

There's always one odd one - and its usually me!

MikeRJ - 20/5/10 at 08:54 AM

Are you running closed loop control?

flak monkey - 20/5/10 at 08:57 AM

No its all open loop now. No EGO correction at any point

graememk - 20/5/10 at 11:09 AM

maybe this problem has always been there hence why the megasquirt wouldnt work....

flak monkey - 20/5/10 at 11:13 AM

Nah there is definately a problem with the old megasquirt. Phil at Extra EFi is testing it at the moment and I had a message last night saying that it

had just started playing up on the bench tester.

Oddly, I never had this problem with megasquirt, it always idled ok.... When I changed everything over I didnt disturb anything like the throttle

bodies/injectors etc.

flak monkey - 20/5/10 at 11:59 AM

Had a little more of a play over lunch time.

The problem doesnt start when the fan kicks in. Its maybe slightly worse, but only by around 0.3AFR.

I struggled to start it from 20deg but this is probably down to my cold start settings.

Once warm the AFR was around 12.5 when running well and 15 when running poorly. Again seems to switch between the 2 every few minutes.

flak monkey - 20/5/10 at 05:44 PM

Thats it, i am officially pi55ed off with this now.

No airleaks that I can find - like I say theres only one joint and thats got new gaskets fitted and the bolts are tight.

It always idled ok with the measquirt, no problems at all. Nothing mechanical has been disturbed. Now it wont idle properly or start when hot, or keep

running when hot when initially started for a few minutes.

There are no corrections affecting it in the ecu that I can see.

It goes from bein too lean to too rich every few minutes, never quickly.

None of the readings from the ECU are odd and none of them change when the problem starts. The speed drops and the ecu adds some ignition to try and

bring it back up.

I have increased the plug gap (stock is 1.6mm) and its not made any difference at all.

Oh and to top it all its due an MOT in a couple of weeks and it needs to idle properly by then!

Bloody thing.

atspeed racing - 20/5/10 at 06:39 PM

I know it isnt convenient to return back to us, but the offer is open for you to do so, no problem. We as a company pride ourselves on our work and

our reputation thrives on this.

You are more than welcome to visit us on Saturday morning and we can see what we can do for you.

Perhaps call us and confirm you are going to be here.

I have gone through the map and i cannot find any possible explanation within it to cause the strange problem you are experiencing.

- colin.

40inches - 20/5/10 at 07:05 PM

This may or may not sound stoopid, have you tried it without the bonnet on? If your setup is still as in your photo archive, with the filter behind

the manifold,and the tubing running under the manifold, may be heat soak? I had a similar problem on a tin top, the temp of the tubing was over 100c.

flak monkey - 20/5/10 at 07:30 PM

Happens with or without bonnet. Air temp constant at 55deg and coolant at 92 when ticking over for long periods. No changes when running well or

poorly. It happens at lower temps as well though. From coolant temps of 60deg upwards I would say.

I had it running for a few mins with it relatively stable, but seems just a fluke as without changing any settings its back to the variation.

OK a little more info...

The swing from lean to rich is consistently 65-70seconds

The swing from rich to lean is consistently 55-60seconds

This is without fail - times taken from timer on ECU.

I cant help but think its something electrical/ecu related as its so consistent in the swings and like i say the problem wasnt there with MS.

I also removed the dump valve and plugged vac line just to eliminate it - no difference.

Colin - getting down sat is not possible I am afraid, the 250mile round trip is a bit much. This isnt anything you have done, as you know it was doing

this before it came down to you. I was really hoping to be able to speak to Andy at Omex but he is away until monday.

[Edited on 20/5/10 by flak monkey]

sebastiaan - 21/5/10 at 07:30 PM

Hi David,

Why does the MAT correction only come in above 60 degC? The difference between 15 and 60 deg C is 15% in air mass! ((273+60)/(273+15)=1,15)

This means that, all else being equal, the AFR will also vary 15% without the MAT correction doing anything about it! This seems like a fairly sure

way to get possibly very damaging detonation. Depending on the control strategy employed, it could also have something to do with your idle problem.

Also, can you run the thing in closed-loop, and if so: why aren't you? The sensor isn't there for nothing....

Sebastiaan

flak monkey - 21/5/10 at 07:42 PM

It was over correcting and making it go lean at higher MAT like when sitting in traffic.

Under power the MAT is pretty stable at 25-35deg.

I know the theory says you need to remove quite a bit of fuel at higher temps but I always found MS took out too much fuel as well. So its safer to

run no MAT correction at higher temps as its less likely to randomly go lean...

sebastiaan - 21/5/10 at 08:25 PM

That just means you are not measuring the charge temperature correctly... OEM software often has a model that predicts the density of the trapped (in

the cylinder) charge, as that's also dependent on the temperature of the inlet system after the MAT sensor and a whole bunch of other

parameters.

If the theory doesn't correspond with practice, that does not mean the theory is flawed, just that you are not applying it correctly.

Anyway, the above is all fairly arbitrary if it is possible to have the engine running in closed-loop. Is this possible?

sebastiaan - 21/5/10 at 08:27 PM

quote:

Originally posted by flak monkey

So its safer to run no MAT correction at higher temps as its less likely to randomly go lean...

I thought you said it only kicked in ABOVE 60 degC? I'm not trying to poke holes in your story, just trying to help solve the problem.

flak monkey - 21/5/10 at 08:36 PM

Its 0.5% at 50deg then 1.1% at 60deg I think.

Running in closed loop is possible but it doesnt really help it still goes lean and rich every minute or so. The trouble is when it goes lean the

mixture jumps around so quickly the lamda cant keep up. When its running slighty rich it runs smoothly and the lamda correction works properly.

sebastiaan - 21/5/10 at 08:53 PM

If it does run in closed loop it should not go rich, unless the end of the control authority range is reached. Any idea what the range is in which the

closed loop can control the mixture? I'd whack it up and see what happens.

If it goes lean the AFR will indeed jump about quite a bit due to (partial) misfiring and improper combustion phasing.

Is is possible to post or send a datalog I could have a look at?

It's bound to be something simple, don't worry.

flak monkey - 21/5/10 at 09:05 PM

Yes it starts missing when it goes lean. Seems happiest running at around 12.5 at idle.

What I have done at the moment is richened the idle so that when rich its 11 and lean is about 13.5. At least like this it keeps running ok.

The lamda has loads of authority - 75% infact - and it only ever uses around 10% if it is enabled. Its set to come on under 1500rpm and 80kpa....

It still tries to go lean with EGO enabled. The regularity of it means I am sure theres something the ECU is doing every 60secs or so that causes it,

but I cant find anything anywhere.

I can post a datalog but I dont think it will tell you anything as I am running Omex now....

[Edited on 21/5/10 by flak monkey]

sebastiaan - 21/5/10 at 09:16 PM

So, does the engine "outrun" the ego correction (i.e. does it go lean quicker than it can correct for it) or does the ego correction clip

somehow? It should not go lean with EGO correction enabled.

If you can / want to post a full datalog (with all parameters enabled if possible) I'm sure I can make at least some sense of it. What type of

Omex are you running? 600?

If you can only select a few parameters, could you at least select:

RPM,

MAP (if you have this)

Ignition angle

MAT

EGO correction %

Vbattery

Injection pulse (total length)

Injector bias

Lambda

And I'll see if I can have a look later this weekend. If possible, could you also send / post the calibration?

Sebastiaan

ps. I've been a full-time engine calibration engineer for some 3 years in the past ;-)

atspeed racing - 24/5/10 at 09:13 AM

what does the fuel pressure do when this happens?

- colin.

flak monkey - 24/5/10 at 09:59 AM

EGO correction certainly doesnt seem to help very much. I would say there is a minor improvement, but when its running lean/rough the fluctuations are

so quick I dont think EGO can keep up.

Fuel pressure doesnt look to change at all - other than the normal minor fluctuations as the injectors open which dont noticeably change.

I think it does this when you are holding a constant road speed as well, although its very difficult to tell when driving along as you are always

varying the throttle. Obviously it's most easily noticed at idle, so if I can solve the problem there then thats a start...

I have mailed Andy at Omex, I know he is back from holiday today, but no doubt is buried in emails....

David

atspeed racing - 24/5/10 at 12:20 PM

its certainly odd. let me know if andy finds anything within the map or omex.

sebastiaan - 24/5/10 at 12:40 PM

EGO should be quick eonough to not let it GET lean and run into misfiring trouble. Can you increase the EGO step speed somehow and see what happens?

I'd combine this with a rich idle (AFR~13) to create a bit of a buffer.

Basically, try playing around with the EGO settings to see if you can avoid the engine going lean. that SHOULD be possible. If you are running large

injectors, it is also paramount that the injector bias / dead time is calibrated correctly since the EGO can only work correctly when those are OK

(i.e. if the EGO correction "thinks" it is adding 10% of fuel, it should also really add 10% of fuel. If the bias correction is out, so will

all other corrections....)

flak monkey - 24/5/10 at 12:45 PM

Yes, I havent fiddled with the injector opening times at all yet. I thought I would leave it well alone as it would affect the fuelling throughout the

rev range wouldnt it?

I know the figures that are currently in the ECU are too long compared with what they should be. But the shape of the curve is the same, just slightly

offset.

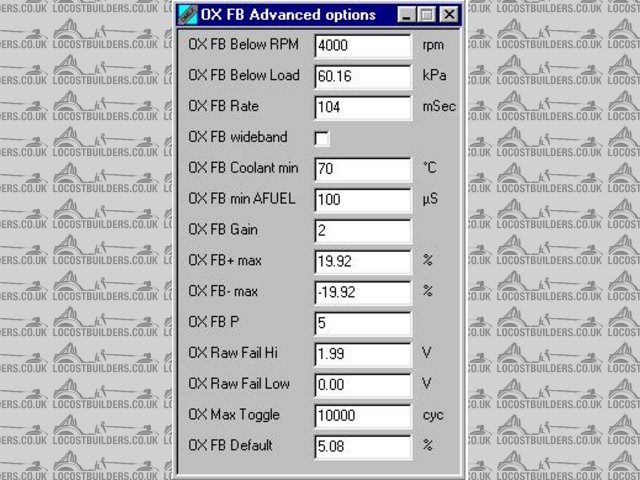

I also havent played around much with the EGO settings. Theres a screenshot below of all the settings that are available. Those shown arent my

settings though, its just a shot frmo the Omex manual.

BTW the datalogs from Omex dont seem to have everything you would need in them. It logs a lot less channels than MS unless there is some way of adding

channels to a log?

Rescued attachment ego.JPG

sebastiaan - 24/5/10 at 02:41 PM

Decrease OX FB rate and increase OX FB gain with a factor of 2 each. That should make the EGO 4 times more agressive. This might cause a mildly

unstable idle, but at the mo, we're just looking for proof of concept (i.e. using the EGO to keep the idle AFR constant-ish)

[Edited on 24/5/10 by sebastiaan]

flak monkey - 24/5/10 at 03:15 PM

OK, I have figured out how to do the logging with Omex (i think) - it only logs the parameters you have displayed at the time. So I have made a

display screen showing the appropriate parameters and will do some logging tonight.

I will log from a cold start and record the times when the problems are seen.

I'll then have a play with EGO and see if that helps.

Thanks,

David

MikeRJ - 24/5/10 at 06:27 PM

I have to share your reluctance to enabling EGO to fix this, it just shouldn't happen in the first place so it feels like a crutch rather than a

fix for the underlying problem. Hopefully the logs will give a clue as to the problem.

atspeed racing - 24/5/10 at 06:48 PM

you shouldnt have to be enabling any additional corrections. that is not the problem. it shouldnt need any corrections at all. that will only add more

complications to the problem.

raise the idle speed to 2000rpm, see if the problem continues.

i think we should be looking at a problem within the car, not the ecu... back to basics... air leaks, manifold vacuum when running, fuel delivery,

fuel supply.

- colin.

flak monkey - 24/5/10 at 07:09 PM

Well, I think I have fixed the problem....i say think because only time will tell.

Started the process of elimination thing...

Whilst doing my datalog I sat there watching the differences between lean and rich and the only thing I could see (other than the obvious) was the

average TPS had increased by around 0.3%.

Colin, you will probably remember you saw some noise on the TPS and sensor outputs before you started working on the car with just the ignition turned

on and nothing running... So this got me thinking.

I disconnected the live and earth to the ECU and connected direct to the battery, no difference at all - same noise.

Then started to think what else was connected with the ignition on.

Flourescent backlight in the dash - no effect

Low pressure fuel pump - no effect.

At this point scratching my head to determine what else is always powered up when the ignition is on...

Only other thing was Lamda sensor (LC1). So I pulled the analog ground which goes to the ECU off and it seemed to stop the noise and also made the

water and oil temps read correctly on the dash.... Hmmm onto something there then I reckoned...

The analog ground is also connected to the ground of the dash - so I wonder if there was some sort of ground feedback loop going on?

Anyway with the analog ground disconnected it seems to maintain whatever mixture you set (actually on the leaner side rather than the richer) and the

dash temps now read correctly too.

I had the car ticking over for a good 15mins with no noticeable changes in the mixture (other than the normal fluctuations I would associate with the

huge injectors).

There is some noise on the TPS signal with the engine running, I would expect this is normal due to small voltage fluctuations etc? Not talking much,

maybe 0.3%?

So I will monitor the situation now and see how it goes from here on in.

I just have my fingers crossed that it still drives OK now the problems been fixed....

I do wonder why the 60 and 70sec swings though. Maybe this is the timing of the heater in the lamda probe or something?

Thanks for your patience!

atspeed racing - 25/5/10 at 08:32 AM

fingers crossed on that one.

99 times out of 100 its the car, not the ecu.

poor earths cause endless problems when we are working down in 0-5v, or 0 - 0.5v scales, a poor earth or slight change in voltage can cause all sorts

of dramas.

keep us informed

- colin.

MikeR - 25/5/10 at 11:35 AM

ironically i was reading this and wondering if there was a problem with your TPS - i didn't think it would be voltage but a dodgy switch sending

strange signals once in a while.

Guess i was almost (in a very oblique way) on the right track.

Good luck & do you think this could have been affecting your megasquirt?

flak monkey - 25/5/10 at 11:44 AM

There was a different issue with the megasquirt, which Phil at ExtraEfi has recreated on the bench so I am confident the issues I was having with that

are unrelated.