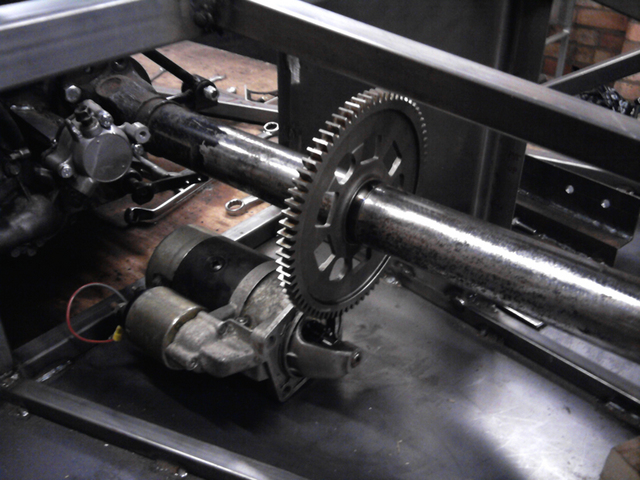

will this work sorry large picture

24vseven - 12/5/10 at 05:59 PM

firstly sorry for the big picture.

in a nut shell given the correct position of the starter motor will this work. the toothed gear is machined acuretly to be a tight fit and central on

the propshaft. when the item is finished the wheel will be shrouded in 3mm steel for protection. and balanced properly. my main concern is will this

cause vibration when running

[Edited on 12/5/10 by 24vseven]

Mark Allanson - 12/5/10 at 06:05 PM

My eyes, my monitors!

Rescued attachment Photo0215.jpg

zilspeed - 12/5/10 at 06:13 PM

Don't like that at all.

Yes, it may be encased in 3mm steel, but if it does go wrong.

It's putting loads of potential stresses onto a bit of the driveshaft which really doesn't need to have such issues putting on it.

The only suitable place for a gear like that is at the end of a shaft.

24vseven - 12/5/10 at 06:17 PM

problem is room at the back is very tight

clairetoo - 12/5/10 at 06:17 PM

/ Agreed !

If that goes walkabouts at any kind of speed , it would probably kill you

Edit - too slow , I was agreeing with Zillspeed

[Edited on 12/5/10 by clairetoo]

Davey D - 12/5/10 at 06:18 PM

Do you have a centre bearing on your prop with a rubber bush? If so gears meshing and turning may flex the rubber bush letting the prop move, and the

gears push away from each other. My electric reverse has the sprocket bolted between the prop and diff flanges. Since the diff is solid mounted the

gears will always mesh properly

24vseven - 12/5/10 at 06:27 PM

fair point never thought of that

NigeEss - 12/5/10 at 07:05 PM

Can you find a starter that rotates the other way and then have the gear cloder

to the end ?

24vseven - 12/5/10 at 07:15 PM

quote:

Originally posted by NigeEss

Can you find a starter that rotates the other way and then have the gear cloder

to the end ?

final position of the wheel is open as its not welded yet

tony-devon - 12/5/10 at 07:24 PM

sorry but thats just wrong

like driving around with a horizontal mill in the car LOL

I would certainly be rethinking that

I have only built them on trikes, but 2 successful electric reverse systems so far

1st was very simple, pivoting electric motor with rubber wheel that acted on a portion of the shaft right by the diff

the second was far better, again an electric motor, from a wheelchair or some sort of electric vehicle

toothed belt and pulley to give the desired gear reduction, but the pulley on the propshaft ran on a large 1 way bearing. even had a speed control on

that version

the common theme being little or no rotating parts during forward motion of the vehicle, and always right up against a supported section of the

propshaft to prevent undue sideloading and stress etc

flak monkey - 12/5/10 at 07:31 PM

Nooo, dont do that

Generally in engineering - if something looks wrong it usually is. And that defo doesnt look right.

I dont know how most do the reverse stuff, but its probably worth talking to mk about how they do it?

Badger_McLetcher - 12/5/10 at 07:57 PM

If you're dead set on that move the gear as close to the UJ as possible, preferably with the starter motor facing the other way (so need to

change direction of rotation).

I'd advise you to find another way if at all possible.

02GF74 - 12/5/10 at 08:13 PM

the further a mass is way from centre of rotation, the greater the vibration if it is out of balancve.

it would not surprise me if the prop would wobble in the middle - the furthest away from both fixed ends and then placing a weighted wheel like that,

not good, as they say.

24vseven - 12/5/10 at 10:49 PM

lol yea i took the if it looks wrong it usally is attitude hence the need for a second opinion so its back to the drawing board we go

MikeRJ - 13/5/10 at 11:22 AM

quote:

Originally posted by 02GF74

the further a mass is way from centre of rotation, the greater the vibration if it is out of balancve.

it would not surprise me if the prop would wobble in the middle - the furthest away from both fixed ends and then placing a weighted wheel like that,

not good, as they say.

And of course there will be a nice bead of weld around the prop with the associated embrittlement in the HAZ. I wouldn't even consider it

personally.

boggle - 13/5/10 at 11:50 AM

how would the starter stay in mesh arrangement with the prop??? the prop will move up and down..