Structure of Rover V8 crank pulley

scudderfish - 11/2/10 at 01:22 PM

I'm figuring out how I'm going to fit my trigger wheel. I noticed that the front pulley is held on by three bolts that go through what I

assume is a dampner and I can feel nuts on the back of this. Can I take the pulley off without having to undo the FO big nut in the middle? If I do

manage it, what is the likelyhood of me being able to get it back on and hit the nuts at the back with the bolts?

I can't attach the sensor on the right where it normally goes as that is where my alternator sits. If I put it on the left then it'll have

to go on the front of the oil pump and will sit further forward. In this position, my trigger wheel would sit between the pulley and the damper

thing.

blakep82 - 11/2/10 at 01:41 PM

i know its a different engine, but thats basically how i did it on my vauxhalll. there's 4 bolts on mine. i just used longer bolts and put the

trigger wheel on the front with them

NS Dev - 11/2/10 at 02:06 PM

The nuts are on a plate (assuming its not been mucked about with), you'll be fine, just done this very thing on a 4.6 rover we're working

on, different front pulley bit but same lump behind it, and same nuplate arrangement.

[Edited on 11/2/10 by NS Dev]

RAYLEE29 - 11/2/10 at 03:46 PM

I have a vague recollection that the pulley on mine was tapped.

should be quite simple to find out loosen the bolts and see if they can be moved in/out and as a whole or independently. should give a good idea what

theyre threaded into.

either independent nuts

nuts captivated on plate

threaded into pulley/damper

hth

Ray

[Edited on 11/2/10 by RAYLEE29]

boggle - 11/2/10 at 04:29 PM

the pulley will come off just fine, the big bolt holds the sprocket on to the crankshaft that drives the timing chain....

boggle - 11/2/10 at 04:30 PM

just a thought...is this a 3.9 efi you are running?

scudderfish - 11/2/10 at 05:22 PM

Thanks for the replies. It isn't 3.9 efi, it's a carbed 3.5 that I'm converting to EDIS ignition with megasquirt. Unfortunately the

crank sensor bracket I bought from triggerwheels.com is meant to go where my alternator is so I'm looking at 'non-standard' ways of

fitting it all. I was hoping to avoid taking off the whole assembly given how tight that nut it.

Paul (Notts) - 11/2/10 at 08:05 PM

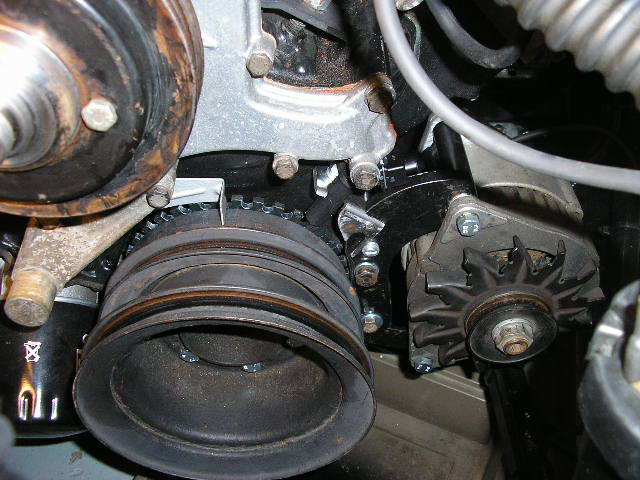

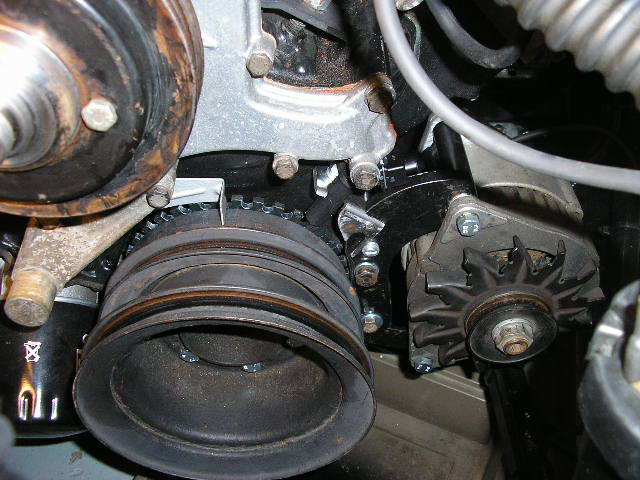

My set up....

if you want to mount the trigger wheel on the front of the pully then I have a spare 5mm spacer that may help, correct bolt pattern for pully.

Paul

Rescued attachment majorca 025.jpg

scudderfish - 11/2/10 at 08:14 PM

That's very interesting. Your alternator is in the same place as mine, but your water pump looks to be offset to the left. Do you have any

other photos of the front end of your engine?

Regards,

Dave

Simon - 11/2/10 at 08:49 PM

Have a look at my blog (link in sig) and go to Tuesday, 1 January 2008 post.

As for removing that bolt, I made a T bar with a 2 1/2 foot handle with a new socket welded to it. So little effort required with the right tool

ATB

Simon

scudderfish - 12/2/10 at 10:49 AM

More progress. It turns out the captive nuts weren't. I heard the dreaded 'plink' as the first bounced across the garage floor. Oh

well, worst case is I have to undo the FO nut to get it all back on, so I'm no worse off really. I ploughed on and got the pulley off. In the

second pic above, you can see some spacers between the pulley and the damper. These fortuitously are the same size as my TW and a spacer, so it all

fits together nicely.

What I need to do now it make up a bracket. There are a convenient pair of threaded holes on the left side.

However they are above the centre line (it was too much to hope for) so I'm going to have a funky angle in there to get the sensor at right

angles to the wheel. Getting in there to measure that funky angle is a bit of a swine. I think I'll end up mocking it up in ABS or something

similar so I can easily heat and bend as appropriate before making the real thing.