Rescued attachment airbox design.jpg

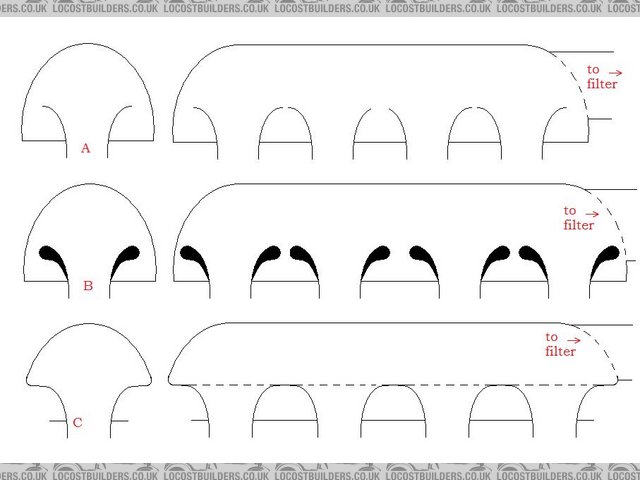

Following on from my recent thread on filters i wondered about making an airbox so i can put the filter in a better position. The Height from the

base plate will have to be the same in each design due to space so which of the following designs would be the best one to go for?

Thankyou.

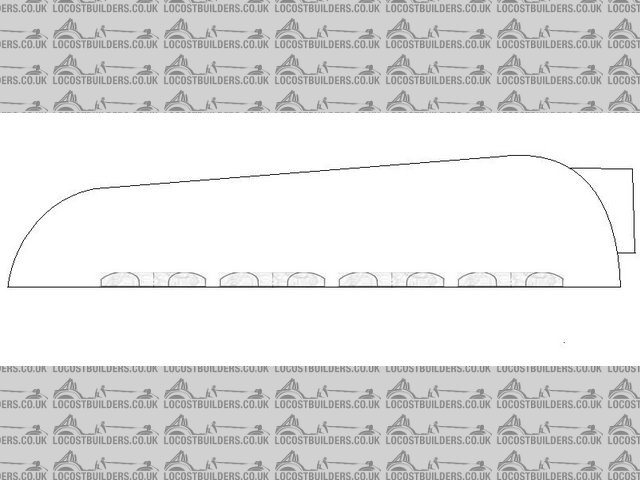

Rescued attachment airbox design.jpg

B or C. Research has shown that sharp edges on trumpets like in pic A have slightly worse airflow than if the rolled edge extends 180° from the

trumpets axis. You don't have to go as far as B. C is also good. If there is plenty of space around the trumpets then B gives you more volume,

which in turn gives less vacuum on each intake of air from the box to the engine. If the trumpets are close to each other and close to the sides then

there's not much to be gained so C may be easier.

The airbox I made was like B.

[img][/img]

You'ld also be better off having a tapered top to the plenum chamber, otherwise the air flow through the chamber will vary from trumpet to trumpet (unless you have a large amount of empty plenum at the opposite end to the inlet. Somewhere I've got a diagram showing drag co-efficient for various trumpet designs, I'll try and find it and post a link...

From rampipe to the top is about 50mm in the smallest place which is why i thought about B. Is max volume always going to be best? I also considered

having a filter on each end but wasnt sure if this would complicate things, different temps, flow etc?

Which way should it taper? should it be wider or narrower, further away from the filter end? Thanks

It should be narrow at the "far" end IE the opposite end to the filter. BUT you want to make sure that there's at least a choke's

width between the mouth of the trumpet and the top of the plenum (otherwise you can strangle the air inlet- unless you get lucky with pulse

tuning).

You really want a plenum at least 1.5* engine capacity. You don't really need a filter at each end but if you can't make a tapered plenum

you'ld be better off having some "spare" chamber at the far end of the chamber (beyond the last trumpet).

Here's the link promised

throttle trumpet design

quote:

Originally posted by andrew-theasby

Is max volume always going to be best?

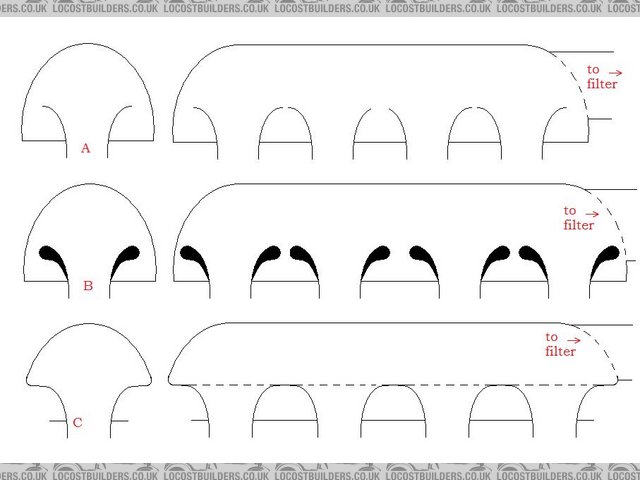

Thanks, Im suprised by 11 being best there. So C with really short rampipes like 11 would be the best of both worlds then as id get more height/volume

in the airbox too. What about the theory of longer ram pipes keeping the peak torque down, would the improved airflow outweigh this? or is 11 not

meant to be used with a backplate on?

Rescued attachment best airbox trumpet design.jpg

You can tune the length for better low down power just as you can put a plate very close to the trumpet throat and get more power. But short of

amazingly complex calculations, these are trial and error approaches which will require some way of assessing how the changes have helped power. And

of course if you're on carbs each change will require re-jetting or mixture adjustment.

The short length, 1-1.5* capacity with choke diameter max between trumpet throat and plenum gives the best outcome most of the time....

Thanks, it was just that summary of the important bits i was after, i wont be developing it, i just want to make one thats of the right style rather than one that loses power, but i think ive got the main bits now in that last drawing. Cheers

What length is the inlet system going to be, either as it is, or the shortest and longest reasonabley possible.