Merge collectors

Benzine - 7/12/08 at 06:17 PM

I'm looking at building my own exhaust at the moment, I've got loads of stainless steel pipe and bends and can weld stainless. I don't

know what to do for the collectors though, as it's a straight six I was thinking of using 2 x 3-to-1 collectors. How would you go about making

them? To buy them is expensive (from the quotes I got, £300 for 2)

This chap has made his own:

http://www.honda-tech.com/showthread.php?t=1761667

From that thread: "

Again this is not the best way to do it, I am sure there are easier ways, but this works out for me and I hope it helps you confused guys out!"

Are there other ways of making them?

but I don't have a bandsaw to make such accurate cuts  I'm not sure either about the diameters of the inlets out outlet of the collectors

and what they should be. I've got 2" headers and I'm guessing the outlet should be bigger but I'm not sure by how much.

I'm not sure either about the diameters of the inlets out outlet of the collectors

and what they should be. I've got 2" headers and I'm guessing the outlet should be bigger but I'm not sure by how much.

Thanks for any info ^__^

[Edited on 7/12/08 by Benzine]

Volvorsport - 7/12/08 at 06:21 PM

minimum 2.5 inch system , 38mm headers would be about right .

dont demon thieves/jetex have 3into 1 collectors ?

i can maybe help you with some more bits.....

blakep82 - 7/12/08 at 06:24 PM

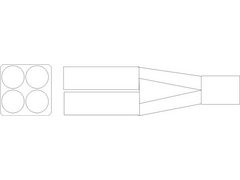

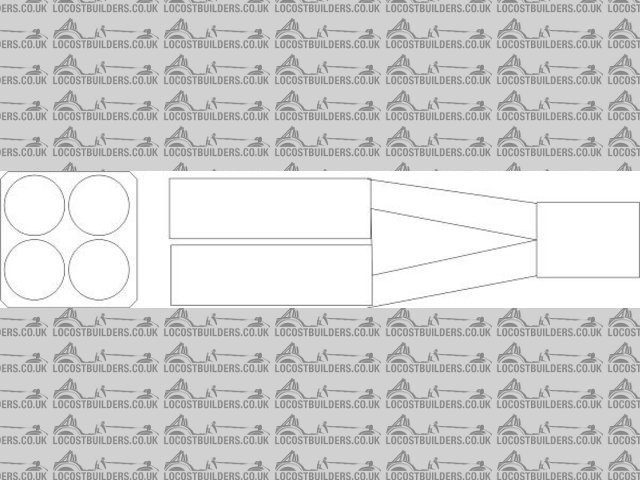

from memory, my staight 6 BMW has 2 headers like this

Description

a bit neater than that though

and then a 2-1 further down

Benzine - 7/12/08 at 06:29 PM

quote:

Originally posted by Volvorsport

minimum 2.5 inch system , 38mm headers would be about right .

dont demon thieves/jetex have 3into 1 collectors ?

2.5 after collectors? 2" at the cylinder head covers the exhaust holes very nicely.

Can't see any on demon tweaks and Jetex said they only do 2-to-1.

quote:

Originally posted by Volvorsport

i can maybe help you with some more bits.....

^____^ i'm listening...

blakep82, that does seem a simple design. I'm guessing it wouldn't flow that well if I made it though T_T

[Edited on 7/12/08 by Benzine]

blakep82 - 7/12/08 at 06:34 PM

well, if you were careful in making holes in the sides of the middle tube, with a flap wheel in a grinder for example, took your time, grinding and

checking all the time, making sure the hole is slightly larger than the tube joining it, and made the joins at 45 degrees (or 135, whatever way you

look at it) then you can't go too far wrong surely?

Volvorsport - 7/12/08 at 06:49 PM

well for a cheapo collector - you could roll a cone , then shape it .

Fred W B - 7/12/08 at 06:58 PM

Some more discussion in THIS THREAD

Cheers

Fred W B

twybrow - 7/12/08 at 07:09 PM

Try this.....

I have another couple of links around about making a 3-1 (my Triumph lump is 3 cylinder, so I have done plenty of searching!). I'll see if I can

track them down....

twybrow - 7/12/08 at 07:31 PM

And another here.....

mark chandler - 7/12/08 at 07:55 PM

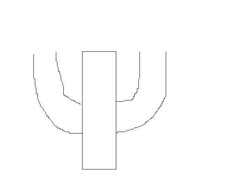

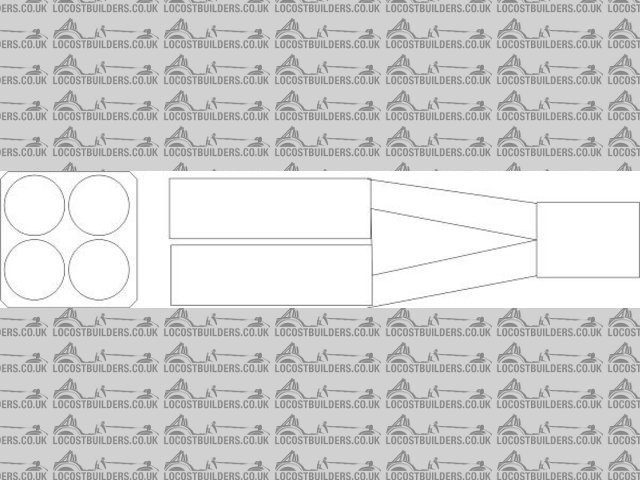

Although cutting and blending them like that looks really cool it does drop power, you really need to make a conical collector that all the tubes

enter.

Two advantages

* no bends required to chop about.

* Easier to make/align

All you do is make a back plate that all the tubes will enter in the same plane, drill holes and weld them in place.

Make a cone that will fit so using a bit of the larger exit pipe split it up to make the sides of the cone, and weld up.

Now all you need to do is cut triangles to in fill, hope the diagram makes sense.

Regards Mark

[Edited on 7/12/08 by mark chandler]

Rescued attachment tubes.jpg

Benzine - 7/12/08 at 08:03 PM

Thanks for all the info, some great ideas ^__^

flibble - 7/12/08 at 08:48 PM

Theres places like this that sell the bit thats awkward to make:

http://www.coneeng.com/collectors.html

http://www.tailpipes.co.uk/retail/retail_tube_1.php?x=Mandarel%20Bends

Might help, you never know

Not used them before though..

Kev

NS Dev - 8/12/08 at 10:20 AM

The one in your first photo is made hpw they should be made ie. best for flow, but not easiest to make.

MikeRJ - 8/12/08 at 10:29 AM

I can remember reading (I think in "Four stroke performance tuning" by A. Graham Bell) that a conical collector was best for power.

I suspect that outright flow would not be as good, but the point of the collector is to create return pulses, and the larger the step change in

diameter, the stronger the return pulse will be.

I'm not sure either about the diameters of the inlets out outlet of the collectors

and what they should be. I've got 2" headers and I'm guessing the outlet should be bigger but I'm not sure by how much.

I'm not sure either about the diameters of the inlets out outlet of the collectors

and what they should be. I've got 2" headers and I'm guessing the outlet should be bigger but I'm not sure by how much.