John P

|

| posted on 19/12/09 at 01:21 PM |

|

|

On going Central Heating Problems. Please help!

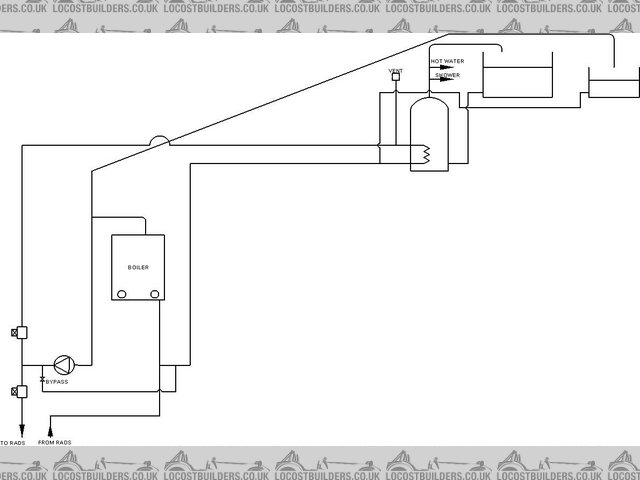

As some of you will know I've been having real problems with air in my heating system and despite checking the various suggestions already

received I am now having to bleed some of the rads virtually every day.

Because this is really pi***** me off I spent a couple of hours exposing the pipes and drawing up a circuit drawing as is.

I have compared this with the circuit given in the Worcester boiler installation instructions (the boiler and controls were new this year but the

basic system is probably 25 years old).

The main difference seems to be that the cold feed should be between the boiler and pump (in fact within 150mm of the expansion pipe) whilst mine is

actually 7 or 8 metres away on the return side of the hot water cylinder coil.

Would this create all the problems I'm getting?

Unfortunately it's not easy to change the cold feed as the boiler is in a flat roofed kitchen and all the pipes go up into the void between the

ceiling and roof.

There is a mains cold water supply nearby if I could somehow utilise that but with such old pipework I'm a bit nervous of a pressurised

system.

Any comments / suggestions.

John.

|

|

|

|

|

John P

|

| posted on 19/12/09 at 01:23 PM |

|

|

Not sure why the picture doesn't seem to work, is this better?

[img]

Central Heating Circuit

[/img]

|

|

|

turbodisplay

|

| posted on 19/12/09 at 01:53 PM |

|

|

Is the heating circuit expansion tank, actually got water in?

My parents system had air when the ball cock got stuck.

Darren

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

t16turbotone

|

| posted on 19/12/09 at 02:07 PM |

|

|

is the vent an 'auto' type or thumb screw type?

|

|

|

rachaeljf

|

| posted on 19/12/09 at 02:08 PM |

|

|

Looks like the head loss in that 7 or 8 m of pipe is enough for the water level in the overflow pipe to be drawn down so that air is being sucked in

where the overflow pipe joins the circuit.

You can try throttling your pump down a bit, or raising the header tank level, or re-routing the cold feed so it comes in nearer to where the overflow

pipe joins.

Cheers R

|

|

|

Bigheppy

|

| posted on 19/12/09 at 05:08 PM |

|

|

The short answer is yes it could cause your problems. Previously you were advised that the hot water coil could be cracked, if this was true the

header tank which is higest would fill the other tank, If both tanks are at the same level it is often difficult to diagnose. If they are at different

levels the lowest would overflow. The cold feed should be connected to the flow pipe ,the one taking hot water away from the boiler, nearest to the

pump with the return connected as close as possible to this pipe. This arrangement puts almost equal pressures on both pipes so helps to stop the pump

pumping water into the header tank and aerating the water, and/or sucking air into the system. Raising the header tank may help but it probably wont

stop any pumping over which aerates the water, this aeration then enters the system and the disolved air contributes to further corrosion of the

radiators as well as causing air locks. A temporary fix would be to connect the cold feed into the expansion pipe below the header tank and fitting a

vent to the original cold feed point on the system, this does not always work. Another fix would be to increase the volume of the expansion pipe,

using en elephant tube! these used to be made fron 11/2" copper tube and dependant on how much vertical space is available up to 1m long. This

would be fitted in the expansion pipe just below the tank. In the absence of a tube this size a series of tubes coule be used, drain the header tank

and cut the expansion pipe then add several tee's with pipes running parallel to the original then join all these together and vent into the

tank as was original. The system should be balanced, first with the system off if you have a gate valve fitted to the flow or return pipe to the

cylinder turn all the way off counting how many turns, then open it to half way. Close the bypass and open it up half a turn. Check which radiator

heats up the fastest then using the rad valve turn it almost off, then turn the next hottest rad on a little more increasing the amount its turned on

until all rads are heating up at the same rate. There types of fixes may work but not having seen your installation I can give no guarantees.

[Edited on 19/12/09 by Bigheppy]

|

|

|

Ferg

|

| posted on 19/12/09 at 07:14 PM |

|

|

I'd agree with the reply above. The vent and cold feed MUST be close together or pumping over is VERY likely. Also as mentioned above, is that

vent an auto vent? If so shut it manually, they are rubbish things.

The only other possible solution is to do away with the cold feed on the return and plumb the existing vent into a 22mm tank connector to form a

combined cold feed & vent. This was pioneered by Baxi for low head systems in the early 80s. BE WARNED though, that it isn't acceptable

unless the boiler has a MANUAL reset hi-limit overheat thermostat.

|

|

|

MkIndy7

|

| posted on 19/12/09 at 07:46 PM |

|

|

If your going to the trouble of altering pipework it might be as well to change it to a pressurised system.

You could then cap off the cold fill and vent and remove the heating header tank.

But you would need to install on the pipework an approx:

20L expansion vessel

A filling loop kit with pressure guage

A 3bar safety valve (vented to outside or a visable drain)

Then once the air is out you should never have the problem again.

|

|

|