tegwin

|

| posted on 9/10/22 at 02:03 PM |

|

|

Loft insulation ideas

In an effort to save money on heating this winter I want to try and improve the insulation of the loft.

Currently its 75mm of compressed ancient glass wool with random doors and things on top to walk on.

Its a conventional cold roof, cement tiles with bitumin type membrane under the tiles.

I see the current trend is for 200-300mm of insulation. Id like to see if I can add 200mm with good space for the insulation to breathe with some

flooring on top to store junk on/get to the boiler that is up there.

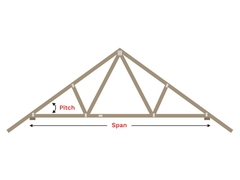

Most plastic loft legs are a bit short and just look proper wobbly. Was contemplating making some light-weight trusses using CLS and OSB

like this and then putting insulation between them with a chipboard floor to cap it off.

Anyone recently tackled this job and have any tips?

Want to spend as little as possible but if I am doing it I might as well try and get the best insulation result I can with some extra storage space

thrown in.

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

|

|

Sanzomat

|

| posted on 9/10/22 at 02:35 PM |

|

|

I did this around 4 yrs back in my daughter's place. The ceiling ties were already 125mm high but with only about 50mm of loose lay rockwool when

they moved in. For the middle section of the roof where its tall enough to walk I fixed some 89x36mm cls studwork timber on its edge screwed through

into the top of the ceiling ties so 214mm tall total. I put two layers of 100mm rockwool in between the ties and it pretty much settled to the 214mm

even with the original 50mm under the 2x100. I boarded over this with 18mm t&g chipboard as the proper flooring grade was cheaper than the crappy

loft panel diy stores sell. Check you can 8'x2' boards through your hatch though. The chipboard running across the extended timbers steadies

it all nicely. Everywhere else where there isn't really enough height to walk I went for 3 layers of 100mm rockwool with the bottom two layers

running with the ceiling ties and the top layer laid at 90 degrees and running over them. The difference going from 50mm to either 300+ or 214 and

chipboard is really noticeable, summer and winter. I also fixed some foil faced PIR onto the loft hatch so there isn't a cold patch.

One other thing to mention, after the first winter we noticed there was condensation forming on the bit of wall above the windows where the lintels

are. I pulled back the bottom two layers of roof tiles and found the lintels are the catnic type steel ones but with no insulation. The rest of the

cavity has previously been filled with expanded poly balls so the lintels were now a big cold bridge. I surrounded the lintels with a couple of layers

of 50mm foil faced PIR wedged in place and that solved that - no condensation since and warm as toast.

Worth checking how much ventilation there is to the roof void. When a fair bit of heat makes it up there a bit of moisture can evaporate. When you

insulate you make the roof space colder and any moisture that penetrates can condense and just hang around so having a bit of air flow keeps it from

going mouldy.

|

|

|

cliftyhanger

|

| posted on 10/10/22 at 06:39 AM |

|

|

we got free loft topup when we moved to our house 10 years ago. There was 4" beftween the joists already.

I took all teh existing loft flooring up first, and use 6x2 timbers to cross the joists. They put the 7" insulation between. I thn popped the old

flooring back.

6x2 not the cheapest option, but very simple. I understand timber prices are falling as the merchants are stuffed full and demand is dropping....

|

|

|

MikeR

|

| posted on 10/10/22 at 07:20 AM |

|

|

I've been wondering about our house and if a half arsed job will cause problems. We've got the standard 100mm insulation, occasionally with

small bits missing where they used to have spot lights. The middle has loft boards with loads of stuff on it. Lifting everything with the plastic

stilts will be a massive job. I wondered if I increased the rest to 300mm would I create a problem having a large boarded area with 100. I'm sure

I've read I will.

|

|

|

Mr Whippy

|

| posted on 10/10/22 at 07:25 AM |

|

|

I think your plan to use the lightweight trusses is a good one, I go for 300mm. I went for a total of 400mm with two 200mm rolls at 90 degs

orientation. Maybe have a look at any grants for improvements, the government seems to run these now and again. That's how I payed for mine but

that was many years ago.

Also hunt out drafts, seal wall hatches, sort drafty windows etc. It all adds up. I you have older windows, an inner additional plastic pane a few

inches away from the glass does wonders. On my sisters ancient farm house we simply got plastic film and taped it to the window frame, difference was

incredible. Mind to burry pipes in the insulation or better still have them under the lot of it. Leave the bottom of the water tank uncovered but

cover the top and the sides.

I work from home and a few months ago moved my desk down to the sunlounge rather than the upstairs back spare bedroom. Don't know why I

didn't think of it before but now I never need the heating on during the day, silly things like that can make a huge difference.

|

|

|

nick205

|

| posted on 10/10/22 at 07:59 AM |

|

|

If your boiler is up in the loft then ensure (if not done already) that all pipes are properley insulated.

Prevent pipes from freezing.

Prevent hot pipes from losing (wasting) any heat.

Seems basic, but so many homeowners don't do these basic things and are losing heat (money) into the atmosphere.

|

|

|

tegwin

|

| posted on 10/10/22 at 09:23 AM |

|

|

Thanks for the replies. I will cost out some options and see what makes sense.

Any thoughts on how thin I could go on OSB for the I beam webbing? Thinking of screwing/gluing roofing baton both sides top and bottom to form the

beams. Some mid span cross bracing screwed in between the I beams to stop them twisting. Plus screw them to existing ceiling rafters.

It’s a loft so I don’t expect heavy traffic or massive amounts of weight!

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

coyoteboy

|

| posted on 10/10/22 at 12:07 PM |

|

|

Personally I think that's defeating 50% of your insulation benefit - you're causing huge cold bridges. Do everything you can to isolate the

boarding from the ceiling or you just bypass the insulation.

|

|

|

tegwin

|

| posted on 10/10/22 at 12:35 PM |

|

|

quote:

Originally posted by coyoteboy

Personally I think that's defeating 50% of your insulation benefit - you're causing huge cold bridges. Do everything you can to isolate the

boarding from the ceiling or you just bypass the insulation.

A fair point for sure. It’s a balance as I’d Like to use some of the space for storage so I do need to be able to support a floor over the insulation.

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

nick205

|

| posted on 10/10/22 at 12:42 PM |

|

|

quote:

Originally posted by coyoteboy

Personally I think that's defeating 50% of your insulation benefit - you're causing huge cold bridges. Do everything you can to isolate the

boarding from the ceiling or you just bypass the insulation.

Good point.

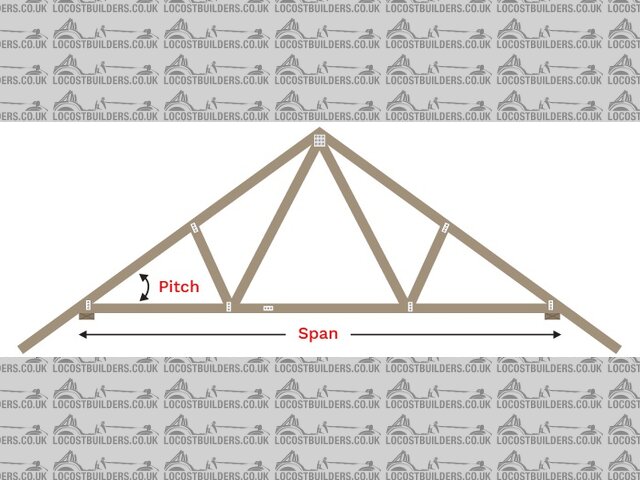

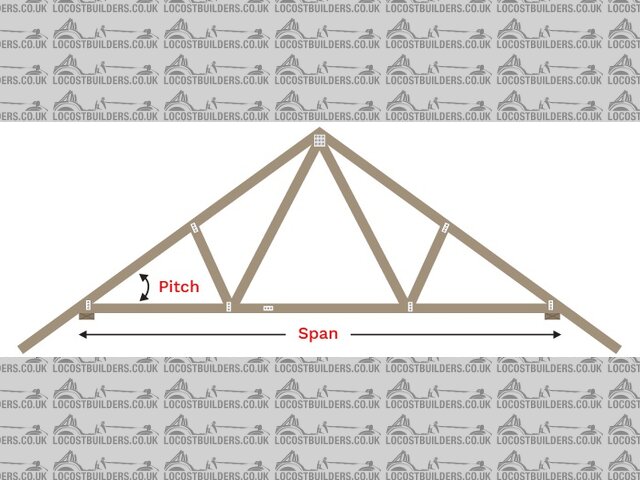

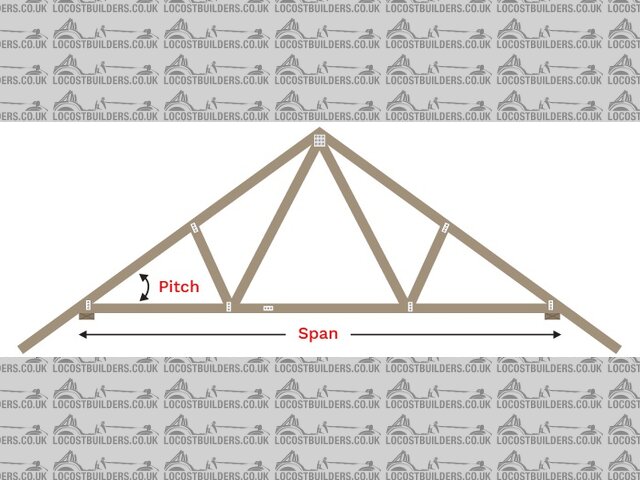

@ tegwin - if you've got roof trusses can you not use the angled sections of the trusses to fix battens to above the insulation and then have

boarding that way?

As you point out it's a loft so not likely to have heavy traffif or high loads for storage.

truss-nick205

|

|

|

tegwin

|

| posted on 10/10/22 at 12:49 PM |

|

|

Hmm it’s quite a span. The joists would end up being quite substantial. I’d also be cautious about loading the roof trusses in that way.

I guess it’s a trade off…. Yes there will be some bridging but the situation will be a lot better than it is at the moment so a net increase in

thermal performance all the same.

Perhaps I need to only board half the loft for storage and leave the rest with extra insulation depth. Less wood so cheaper as well!

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

nick205

|

| posted on 10/10/22 at 12:59 PM |

|

|

quote:

Originally posted by tegwin

Hmm it’s quite a span. The joists would end up being quite substantial. I’d also be cautious about loading the roof trusses in that way.

I guess it’s a trade off…. Yes there will be some bridging but the situation will be a lot better than it is at the moment so a net increase in

thermal performance all the same.

Perhaps I need to only board half the loft for storage and leave the rest with extra insulation depth. Less wood so cheaper as well!

Logical thinking.

Also store less stuff up there - is it really stuff you need.

Adding my loft insulation encouraged me to just get rid of stuff that was in the loft and had been for quite some time (untouched). It's now not

used as a storage space and helps reduce the level of stuff we have that we really don't need.

Some might even be saleable to raise some funds for the insulation too!

|

|

|

nick205

|

| posted on 10/10/22 at 01:30 PM |

|

|

I can also say that I'm glad I did ours (must be 12 years ago now). Definitely makes a noticeable difference in how well the house retains it

warmth. Means we don't need the heating on as often or that high.

When you're fitting it wear long sleaves, gloves and ideally a mask. The itching potetntial is massive so it can't be doing your skin much

good.

Other tip is fit a layer of insulation to the loft side of your loft hatch (I used Celotex stuff). That's another spot where heat can disappear.

|

|

|

tegwin

|

| posted on 10/10/22 at 01:35 PM |

|

|

Ooh yes.. bring on the itch.

I currently have a metal loft ladder that slides up into the space where the insulation will need to be.

My plan is to get a new larger hatch with a folding wooden ladder that fits within its footprint.

I can then make a vertical "tunnel" above the loft hatch to hold the insulation back. Was then going to make a secondary insulated hatch

that swings open into the loft. That way it should be easier to seal it off

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

nick205

|

| posted on 10/10/22 at 01:42 PM |

|

|

quote:

Originally posted by tegwin

Ooh yes.. bring on the itch.

I currently have a metal loft ladder that slides up into the space where the insulation will need to be.

My plan is to get a new larger hatch with a folding wooden ladder that fits within its footprint.

I can then make a vertical "tunnel" above the loft hatch to hold the insulation back. Was then going to make a secondary insulated hatch

that swings open into the loft. That way it should be easier to seal it off

...you're on it

I removed my old (existing) telescopic metal loft ladder altogether and use my step ladder to get up there.

|

|

|

Sanzomat

|

| posted on 10/10/22 at 05:10 PM |

|

|

quote:

Originally posted by coyoteboy

Personally I think that's defeating 50% of your insulation benefit - you're causing huge cold bridges. Do everything you can to isolate the

boarding from the ceiling or you just bypass the insulation.

Timber and timber products actually have a pretty reasonable U value so using timber spacers won't cause significant cold bridges and as the

cross sectional area of the timber versus the area of the insulation is tiny it'll make negligible difference. If it were metal spacers then

maybe you'd get cold spots and condensation risk but not with timber.

|

|

|

Sanzomat

|

| posted on 10/10/22 at 05:13 PM |

|

|

quote:

Originally posted by nick205

quote:

Originally posted by coyoteboy

Personally I think that's defeating 50% of your insulation benefit - you're causing huge cold bridges. Do everything you can to isolate the

boarding from the ceiling or you just bypass the insulation.

Good point.

@ tegwin - if you've got roof trusses can you not use the angled sections of the trusses to fix battens to above the insulation and then have

boarding that way?

As you point out it's a loft so not likely to have heavy traffif or high loads for storage.

truss-nick205

Absolutely don't fix anything to the truss uprights - these are designed to only ever work in compression or tension so are pretty spindly and

even small sideways forces can cause them to buckle. The bottom chord of the truss will have some capacity for load though.

|

|

|

Charlie_Zetec

|

| posted on 10/10/22 at 06:50 PM |

|

|

Having recently completed a house extension, I can tell you all about the joys of rock/mineral wool and Celotex!

Extension to the side of the ouse had to have 225mm of Celotex (or similar) insulation to meet current building regs - according to the inspector.

Whilst not the cheapest, I do recall reading that the thermal efficiency of compressed foam with silver backing equates to double it's thickness

of mineral wool. However, I found that rockwell is a better noise insulator. Both are equally as horrible to cut/handle/lay!

On the existing house in the loft, I had 150mm of rockwell, and just rolled out another 100mm thickness over the non-boarded areas (strip down the

middle) to give extra insulation. Although this wasn't a requirement of the extension work, it does make sense!

Also the new loft hatch has to have a specific minimum U-value, so the one I fitted has a slab of polystyrene on the back of it as purchased. Loft

ladder catches one side as you pull it down, but no doubt it'll wear its' own pattern in due course.

If i were in your position, I would consider squeezing in a touch more rockwool in between the joists if possible, then battening perpendicular to

existing joists (2" square baton), and adding a layer of 50mm Celotex material. Once down, board over the top with the proper 15mm green board

T&G. Get that in, and you'll be hunky dory. Celotex is more expensive, but you're paying for the convenience of thinner material to

give more space (and less wood required as you don't need larger timbers and noggins).

Just remember if you've got downlighters or similar that you should have bowls over the back of them to keep rockwell off, and Celotex should

have about a 75mm radius around the outside. You'd be surprised how many people don't do this, and although probably overkill for modern

lights, is stipulated for a (safety) reason....

[Edited on 11/10/22 by Charlie_Zetec]

Artificial intelligence is no match for natural stupidity!

|

|

|

tegwin

|

| posted on 10/10/22 at 07:04 PM |

|

|

Charlie. An interesting thought re celotex. Will have a look and see what works out cheaper. As you say the wood is expensive.

Rockwool in my mind conforms easier around stuff than celotex so may be easier to fit.

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

Sanzomat

|

| posted on 10/10/22 at 07:43 PM |

|

|

Just one warning regarding using something like celotex above rockwool. If you have no vapour barrier at ceiling level (polythene sheet above the

plasterboard) and even if you do, some moisture vapour is likely to make it up from the warm area below. As warm air cools down any moisture within it

will condense into water. The dew point is likely to be somewhere within the insulation as that is where the temperature gradient is greatest. If you

have, say, 100mm of rockwool and then 50mm of celotex (PIR - other brands are available!) it is almost certain the dew point will be within the

rockwool. The PIR, particularly as its foil faced, will be impermeable so any moisture within the rockwool will be trapped forever and will reduce its

insulation value and may well rot the roof timbers. If its all rockwool any condensed moisture will eventually dry out, either by having good

ventilation or in the summer when its hot in the roofspace. I would not advise PIR above rockwool for that reason. It could be argued that the

boarding above rockwool would do the same but chipboard is actually vapour permeable.

|

|

|

nick205

|

| posted on 11/10/22 at 07:22 AM |

|

|

quote:

Originally posted by Sanzomat

quote:

Originally posted by nick205

quote:

Originally posted by coyoteboy

Personally I think that's defeating 50% of your insulation benefit - you're causing huge cold bridges. Do everything you can to isolate the

boarding from the ceiling or you just bypass the insulation.

Good point.

@ tegwin - if you've got roof trusses can you not use the angled sections of the trusses to fix battens to above the insulation and then have

boarding that way?

As you point out it's a loft so not likely to have heavy traffif or high loads for storage.

truss-nick205

Absolutely don't fix anything to the truss uprights - these are designed to only ever work in compression or tension so are pretty spindly and

even small sideways forces can cause them to buckle. The bottom chord of the truss will have some capacity for load though.

Point taken here and I should have been clear above that I'm certainly not a builder or structural engineer!

I'd got the idea from the previous occupiers of my house. They'd boarded the bottom chords in the centre and done as I describe to run a

Hornby model railway round the truss uprights. A micro-load in comparison to humans and their stuff.

[Edited on 11/10/22 by nick205]

|

|

|

Charlie_Zetec

|

| posted on 11/10/22 at 10:39 AM |

|

|

quote:

Originally posted by Sanzomat

Just one warning regarding using something like celotex above rockwool. If you have no vapour barrier at ceiling level (polythene sheet above the

plasterboard) and even if you do, some moisture vapour is likely to make it up from the warm area below. As warm air cools down any moisture within it

will condense into water. The dew point is likely to be somewhere within the insulation as that is where the temperature gradient is greatest. If you

have, say, 100mm of rockwool and then 50mm of celotex (PIR - other brands are available!) it is almost certain the dew point will be within the

rockwool. The PIR, particularly as its foil faced, will be impermeable so any moisture within the rockwool will be trapped forever and will reduce its

insulation value and may well rot the roof timbers. If its all rockwool any condensed moisture will eventually dry out, either by having good

ventilation or in the summer when its hot in the roofspace. I would not advise PIR above rockwool for that reason. It could be argued that the

boarding above rockwool would do the same but chipboard is actually vapour permeable.

You're right - but if you look at most Celotex installs, there's usually a slight gap or "breathable" area in the install. I

helped a friend do exactly what I said above; rockwool base (already installed), batten above, and Celotex in between. I was advised that there

should be a gap between layers - beams were 6" and we had about 100-120mm of wool in there - and that not everything should be

"squished" in. He chose additional 2.5" timbers and 50mm Celotex, giving an air movement gap of 25mm above and below. Plus the

insulation didn't go right to the outer edges of the eves, and then you've got (well, should have) the vented soffits to allow for flow. We

then boarded with 15mm green board T&G (the moisture proof stuff recommended for bathroom floors). His is always toasty, and whilst not up to

current building regs standard (not necessary for existing buildings), is very good.

Artificial intelligence is no match for natural stupidity!

|

|

|

pigeondave

|

| posted on 11/10/22 at 12:57 PM |

|

|

quote:

Originally posted by tegwin

Ooh yes.. bring on the itch.

I currently have a metal loft ladder that slides up into the space where the insulation will need to be.

My plan is to get a new larger hatch with a folding wooden ladder that fits within its footprint.

I can then make a vertical "tunnel" above the loft hatch to hold the insulation back. Was then going to make a secondary insulated hatch

that swings open into the loft. That way it should be easier to seal it off

Does larger hatch mean cutting a bottom chord?

If so could you record it as I'd like to see how much it pings when you release the tension.

Many thanks

|

|

|

tegwin

|

| posted on 11/10/22 at 01:04 PM |

|

|

Haha no,

Just a ceiling rafter. Will be screwing in temporary trimmers whilst I fit a proper one anyway to reduce any movement to the plasterboard as possible.

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

coyoteboy

|

| posted on 11/10/22 at 03:01 PM |

|

|

quote:

Originally posted by Sanzomat

quote:

Originally posted by coyoteboy

Personally I think that's defeating 50% of your insulation benefit - you're causing huge cold bridges. Do everything you can to isolate the

boarding from the ceiling or you just bypass the insulation.

Timber and timber products actually have a pretty reasonable U value so using timber spacers won't cause significant cold bridges and as the

cross sectional area of the timber versus the area of the insulation is tiny it'll make negligible difference. If it were metal spacers then

maybe you'd get cold spots and condensation risk but not with timber.

Ya think? I have condensation spots on my ceilings from the roof timbers that come through 400mm of wool.

|

|

|