Frivolous use of a CNC machine...

bimbleuk - 7/2/07 at 07:29 PM

OK so my crank sensor disc was delayed so I went over to the machine shop to apply a little pressure!

When I got there the crank pulley had been finished but the timing sensor support bracket needed machining.

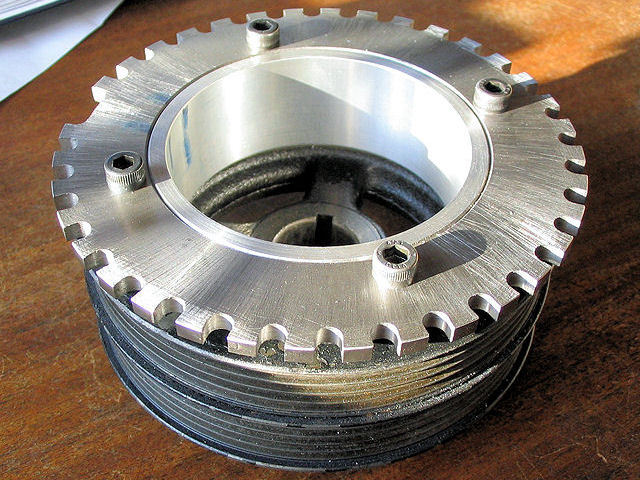

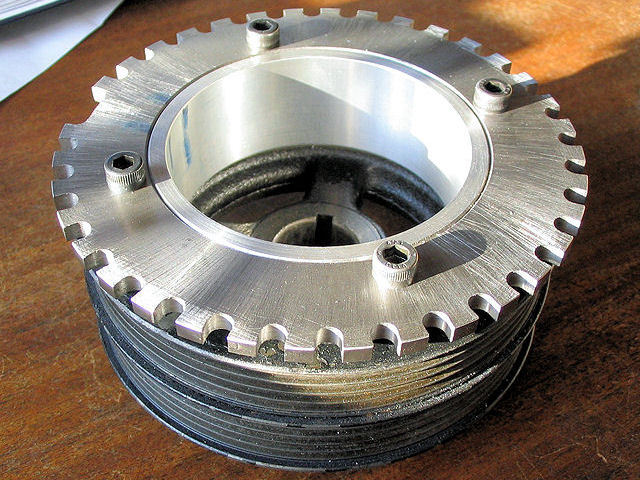

Anyway first picture is of the crank pulley with the timing disc attached. Perfectly good use for some tastey machinery .....

Timing disc fitted

I got talking to the operator and being inquisitive I wanted to know about the CNC milling machine. So I got to play a bit with the bracket and came

up with the following .....

CNC'd crank sensor bracket

You won't even see it cus its under the engine but I know its there. Oh and it says RAW cus my car is a RAW Engineering Striker

bigandy - 7/2/07 at 07:31 PM

I thought it said "PAW" for a moment there

Cheers

Andy

RichardK - 7/2/07 at 07:33 PM

You do need to keep that "operator Sweet", people who can do stuff like that need to be your friends!!!

Nice job with the bracket btw

Rich

Guinness - 7/2/07 at 07:57 PM

Nice work!

I'm about to order a 6' x 4' sheet of stainless that I'm getting laser cut for work. Trouble is I'll end up with about

2' x 4' off cut.

Unless I can think of something else to get laser cut?

Mike

wilkingj - 7/2/07 at 09:09 PM

quote:

Originally posted by Guinness

Nice work!

I'm about to order a 6' x 4' sheet of stainless that I'm getting laser cut for work. Trouble is I'll end up with about

2' x 4' off cut.

Unless I can think of something else to get laser cut?

Mike

A Grill or Emblem to go in the Grill area.

Badges for the front / back / sides of the car, plus a few "Locost" and "V8 Viento" type things as well to sell on here

You can earn several brownie points on here doing that sort of thing.

indykid - 7/2/07 at 10:00 PM

i made this gearknoab at technical college as part of our uni course. all CNC'd

shame i'm never gonna use it. i prefer my carbon ball though

tom

Rescued attachment knob.jpg

TangoMan - 7/2/07 at 10:32 PM

quote:

Originally posted by Guinness

Unless I can think of something else to get laser cut?

Mike

You could always use it to cut me a surround for my exhaust exit hole.

I would supply a template in paper of course and some beer tokens to lubricate the machinery

bimbleuk - 8/2/07 at 08:25 AM

Definitely gonna keep the operator stocked on goodies cus we spent a couple of hours on it. It was using the engraving option which he doesn't

get to play with much. Made a change to the usual routine I suppose and it only cost me some beer money!