Making aluminium pressings

tegwin - 18/3/12 at 05:37 PM

Usually you can find something on google about almost anything, but this seems to come up with very little..

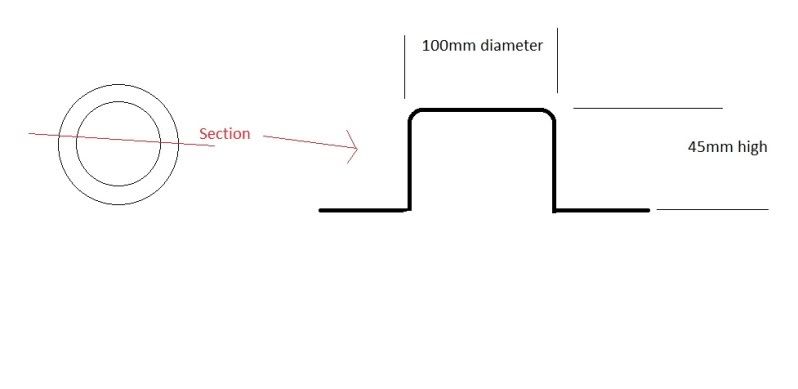

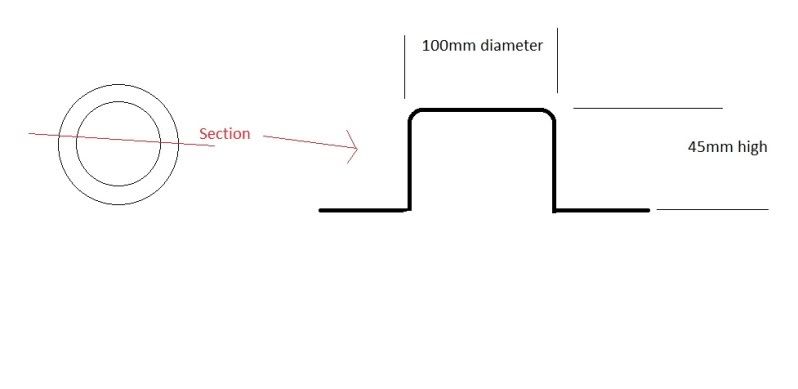

If I wanted to take a piece of 1 or 1.5mm aluminium sheet and turn it into a top hat shape like this (a bit like a mug with a big rim): [the vertical

walls could be tapered to aid release)

Could this be done with a car bottle jack, suitable steel frame and some oak formers machined into a suitable shape?

How would one determine the shape of the former to achieve the correct end result and the force required?

[Edited on 18/3/12 by tegwin]

snakebelly - 18/3/12 at 05:57 PM

Probably far better getting this spun, I have a number for a chap in redditch who does one offs for reasonable money

Talon Motorsport - 18/3/12 at 06:00 PM

You would have to aneal (sorry speelzing not my strong point) heat the material to get the alloy pliable enough to be formed even a 1/4 of that

depth. I think you are being over optimistic with the depth that you are going for from one piece of material. It well might tear or just be so

puckered on the flat out side of the 'pot' you might have to increase the thickness of the material so it stretches. Is there any reason

that this could'nt be a tube welded to a plate, capped and dressed to finish besides maybe not having access to a TIG?

[Edited on 18/3/12 by Talon Motorsport]

tegwin - 18/3/12 at 06:02 PM

Mostly cost really... I could knock up a press for very little money...

hmmmm......

plentywahalla - 18/3/12 at 06:32 PM

You need a high energy rate forming to get that sort of draw depth out of a sheet of Aluminium. The material reacts very differently depending on the

speed of pressing.

In a power press, where the whole operation takes a split second the heat generated is unable to dissipate through the material and so allows the

metal to flow into the required shape. If you do the same thing very slowly with a hydraulic jack the material will just shear.

perksy - 18/3/12 at 07:02 PM

Served my time as a jig & toolmaker and spent 12 years on die try-out

Sorry but you won't be able to do that with an hydraulic jack

45mm is also a fair old depth (depth of draw)

How critical are the dimensions ?

Could you not get them spun or fabricated ?

907 - 18/3/12 at 07:04 PM

I wanted to press these

Description

but my first attempt just made me smile

Description

Back to the drawing board.

Paul G

NigeEss - 18/3/12 at 07:59 PM

So it needs to be done very quickly.

Make your suitable dies, then, how accurate are you with a sledge hammer ?

gazza285 - 18/3/12 at 08:01 PM

I can't help with the problem, but I love Paul's smiley faces.

paulf - 18/3/12 at 08:57 PM

Spinning them over a former is the only viable way of doing this at home, it would still probably need to be annealed a couple of times to get the

shape.

When cans a produced they are stamped out from a slug of alloy in a few milliseconds, if you find some video of a can factory they appear to just

instantly grow when the press hits them.

Paul