PCB design and manufacture..... problems

tegwin - 16/2/11 at 04:53 PM

Is anyone knowledgeable on the design and manufacture of PCBs?

I am trying to design a very simple board in Eagle, the board has 2 SMD components... However, they need thermal vias drawing on...

My plan was to have them manufactured by Olimex.

First, anyone know how they make Vias? Obviously the idea is that there is a plated hole that joins 2 tracks/copper areas.. but do the vias get filled

during board manufacture of as part of the "reflow" process when the components are fitted?

The issue is that, I was planning to solder the componenets on by hand... obviously I would struggle to manually fill the vias if needs be...

If anyone has experience of Olimex and or Eagle and wants to earn some pocket money... Speak up!! I could do with some 'elp!

Tinks1 - 16/2/11 at 05:17 PM

When the boards are manufactured professionaly they edge plate the vias thus forming a circuit

top to bottom.

If you are making the board your self could you put a small piece of copper wire in the hole you make

for the via and solder both sides of the wire, hence forming a circuit top to bottom.

ChrisW - 16/2/11 at 05:18 PM

I'd love to help, but it sounds like you're way ahead of me with this. I've had a go with Eagle, but never actually had a board made

from a design I've made with it. Last time I produced a PCB we had to draw it by hand in a CAD package on an Acorn A3000 and make it by hand in

an etch tank!

However, I'm at the risk of hijacking your thread... are that Olimex lot any good? I do have a design that I want to produce, just not found

anyone cost effective to do it for me!

Cheers, Chris

Confused but excited. - 16/2/11 at 05:23 PM

Oo it's all gone technical.

When I did them back in the day it was all Letraset or Mecanorma rub down transfers onto polyester film.

Double sided boards had little pins that got soldered on both sides to make a through connection, for prototyping.

Ah well, i suppose I'd better get this last pyramid finished.

rf900rush - 16/2/11 at 06:03 PM

Hi

Vias are not normally fill at manufacture of the PCB

If the components are soldered by solder wave then they will be filled with solder.

If solder paste is used then they won't.

Soldering by hand they can be fill at will.

Or by mistake if near enought to a soldered joint.

Hand soldering can somtimes be easier if used with a liquid/gel flux.

Some SMD IC's are a real PITA

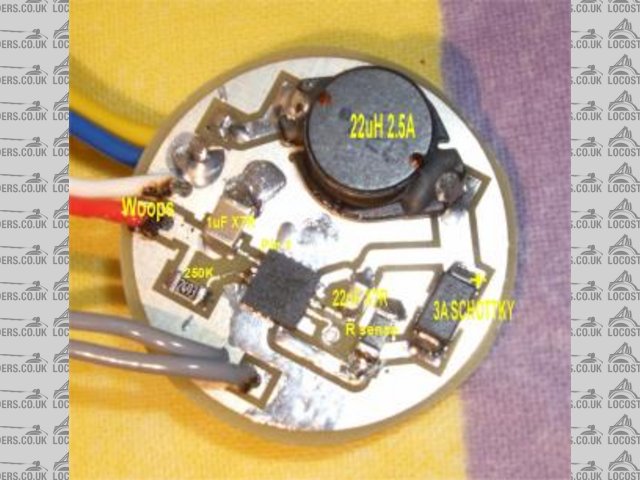

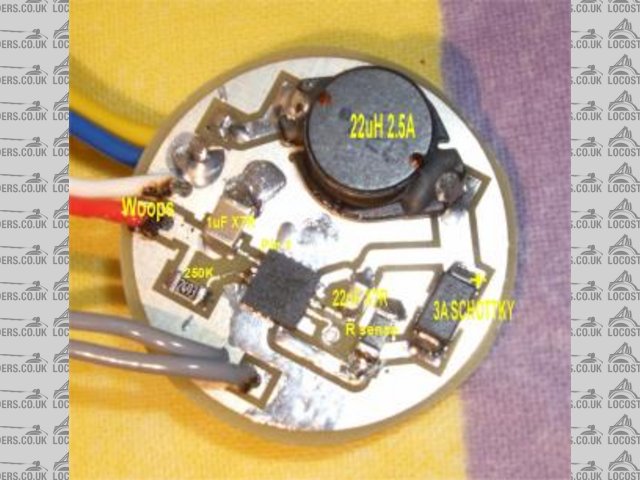

For example the Square divice here is about 5mm square with 16 pins a centre heak sink pad.

Needs a good clean fine tip for the pins and alot more heat for the centre pad.

LEDLAMP1

Martin

tegwin - 16/2/11 at 06:14 PM

Fortunately the components are fairly large (3x6mm)... with 2 pins and a large heatsink under..

I was planning to use solder paste to attach the LEDs.... but was not sure how to deal with the Vias...

I guess I will just have to figure out eagle and draw some vias and see what happens..... :s Its a damn complicated process producing all the files

etc..

Not used olimex before, but their prices are reasonable and they have enough info on their website to help you understand most of the process... Not

that its simple...

trextr7monkey - 16/2/11 at 10:03 PM

We have a simple set up for producing pcbs: light sensitive board then through a mega etch tank, have done a few one offs for people but it can't

be an overnight or often a same week service ( and it gets worse in all the holidays  ) as we have quite a lot on, but happy to help out people on

here when we can.

) as we have quite a lot on, but happy to help out people on

here when we can.

atb

Mike

tegwin - 16/2/11 at 10:12 PM

Hi Mike.

I have made boards in the past using photo resist... but it gets a bit of a nightmare when you want to put on Vias... although not impossible I

guess...

Where do you get your photo-resist PCB from? The only place I have found it is Rapid... but they only sell really thick stuff...

trextr7monkey - 16/2/11 at 10:18 PM

Most of the stuff is from Rapid we also buy some stuff from Mega,

rf900rush - 16/2/11 at 10:58 PM

Just a thought

You Mentioned LED's.

Not high power LED's by any chance.

The round PCB above is an Microchip controled LED driver for Bike lamps. (2Amps+)

Made for these DIY lamps.

Lamp2

tegwin - 17/2/11 at 11:54 AM

They are indeed very high power LEDs... But the package I need to fit them in to is MUCH smaller than that light unit... and because its a bespoke

shape... I need a bespoke board...

Edit to say.. Found that Mega sell a Flexii photo resist PCB with a 5um thick polyester base...

If I could use that.. I wont need thermal vias... simply bond it straight onto some alloy to make some metal core PCB... Me liky...

Just wonder if it will handle "hand soldering" of the SMD components.

[Edited on 17/2/11 by tegwin]

rf900rush - 18/2/11 at 08:20 AM

Is this product like the Flex connections you find in CDrom/hard drives/Mobile phones etc

like this

If so I have just had to solder to a Flex connector. Rearly not easy and does melt.

Simple answer would be to ask the supplier for some data.

The round pcb (last page) I had made by these people. LINKY

I used thier PCB train Express (1 day turn around) for prototypes and low volumes. You can also get online prices.

There are some guide lines for the Artwork files they need.

I use a "veiwmate" Gerber veiwer to check the files.

Do expect £45-£60 fir one PCB. The cheapest is £30 + post + VAT

For rearly good heat transfer I have seen some Alumium back PCBS's

iank - 18/2/11 at 06:52 PM

PCB pool take the brd files from Eagle and make the boards from that - no messing with gerber and excellon files.

They also do aluminium cored boards for maximum heat dissipation, though they are very expensive for small quantities.

http://www.pcb-pool.com/ppuk/info_pcbpool_alupanel.html

Similar prices for 1's and two's compared to PCB train, though PCB train are much cheaper if you want more than prototype quantities.

Download their design rules file for eagle and check the board before you send (won't be a problem unless you want really fine tracks).

[Edited on 18/2/11 by iank]

Werner Van Loock - 18/2/11 at 07:34 PM

We use http://www.eurocircuits.com/ at work. 1st class work.

We made some 4 layer pcb's with a whole bunch of via's and solder masks.

They also do prototype batches.