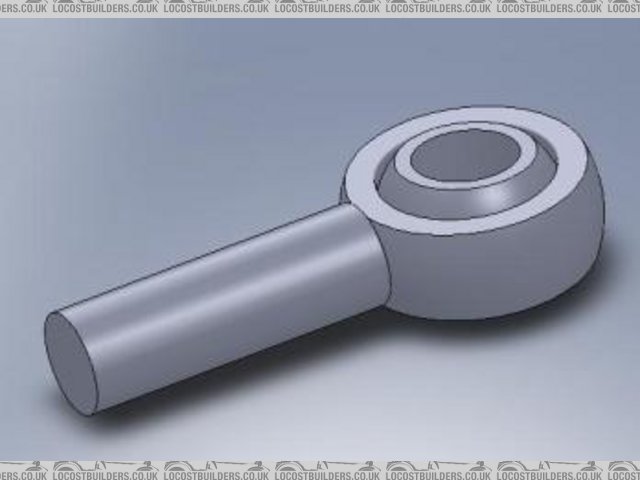

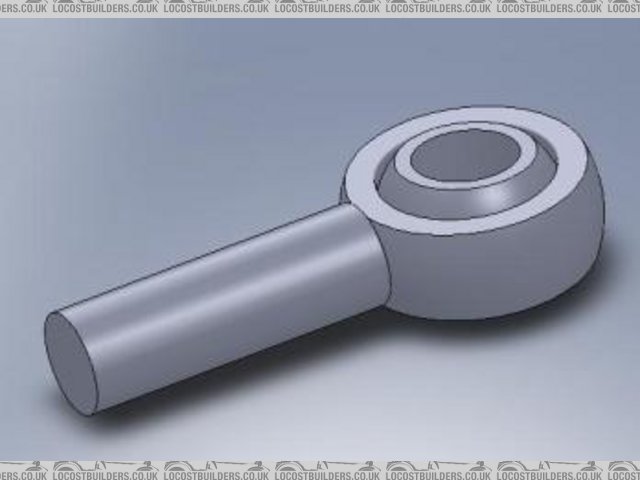

Rose Joint

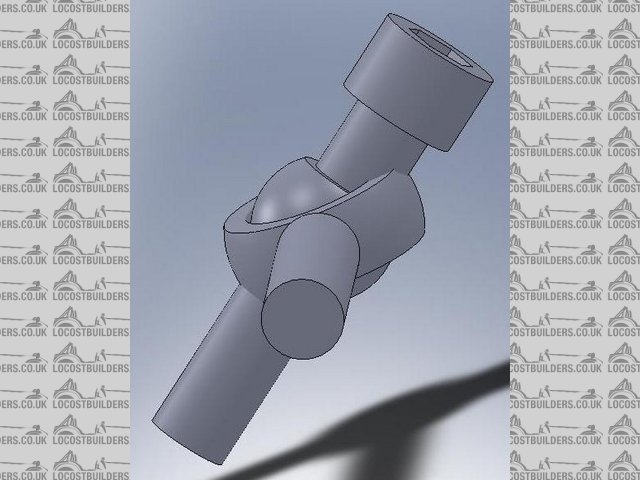

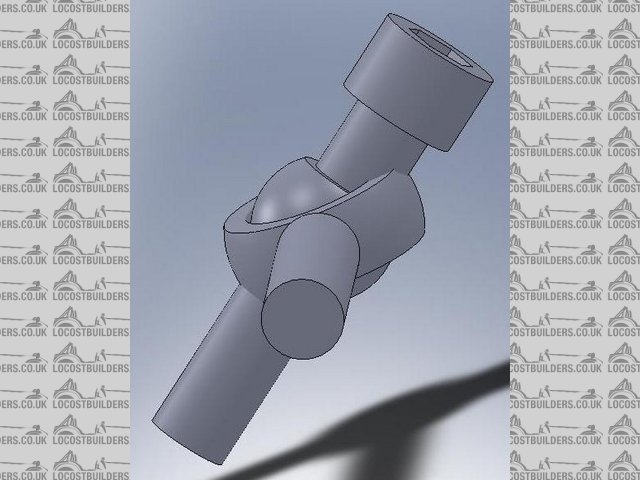

But when i put a bolt through it, and mate it etc, i can get this result.

Rose Joint with Bolt through

Does anyone know how i can limit the movement, so metal does not go through metal.

Many thanks

I have created a rose joint as below

Rose Joint

But when i put a bolt through it, and mate it etc, i can get this result.

Rose Joint with Bolt through

Does anyone know how i can limit the movement, so metal does not go through metal.

Many thanks

You can choose to stop on interference when moving a part, this is a fairly heavy process though, thats why its not enabled by default.

A Limit mate might be a solution as well, but I don't think it'll work on a rose joint.

What version of Solidworks do you have?

Depending on the version, you may be able to use a "Limit" mate. For a rose joint like this, which is basically a ball and socket, you can

define an "Angle" mates between the axis of the hole in the ball of the joint, and the axis of the socket side of the rose joint (i.e. the

main body.

When in the mate dialog box, just click on the "advanced mate" box to get to the details you need.

Hold on a moment, it is easier to describe with an example.... I'll upload one in a min (In SW 2007)

Cheers

ANdy

Right,

Download this zip file, and extract it to a folder somewhere. Open the assembly, and have a go at dragging the ball around. Notice how it stops at a

certain angle.

I think this is what you are after? To se ehow this has been set up, look at the mates, in particular the LimitAngle mate at the bottom.

Let me know if it is of any use, and where I should send the bill

He heh!

He heh!

Cheers

Andy

Oh, the link might help!

www.andy-sayle.co.uk/temp/ball socket.zip

Oh, and you can use limit mates on angles, and dimensions. Pretty useful for assemblies that have moving parts limited by end stops (eg sliding

parts, rotating parts etc). It saves you from having to turn the Physical dynamics on when moving parts around too.

The Physical Dynamics enabled causes a hell of a load on a PC, especially if the assembly is complex. It is also pretty flakey unless you have taken

into account its "needs", which is why Solidworks have started to introduce more mates to control the same sort of things.

Interestingly, on SW2009 (not sure about 2008) there is a friction mate too..... Not really relevant here, but interesting for a geek like me!

Cheers

Andy

Andy - many thanks for all the assistance.

I am using SW2009.

I see what you have done, and will translate it to my parts and give it a go.

It is nice to know that hopefully (one day) that i can see exactly what my front suspension will be like, and how it acts

No worries. If you need any further help, give me a shout, I'm always happy to help where I can

Cheers

ANdy