RichieC

|

| posted on 15/2/06 at 08:55 AM |

|

|

DIY Rivnut tool

Hi all, managed to strip the threads out of my M6 mandrel so I can no longer use my rivnut tool. Is there an easy DIY way of setting an alloy rivnut

up to M6? Surely its just a case of fitting a plate between the surface and a bolt through the middle with the rivnut screwed onto the bolt?

Does this sound right or am I talking rubbish, any photos or drawing would help as Im going to have to make a new tool today.

Thanks

Richie

|

|

|

|

|

ditchlewis

|

| posted on 15/2/06 at 09:02 AM |

|

|

i've had problems with rivnuts in the past, so i used to use that liquid metal glue and then rivnut. not sure if the glue would be enough to

hold it untill the rivnut starts to crimp up of not. its just and idea. i have had some success with this method though, usually small diameter

bolts.

ditch

ps if you have a good quality rivnut tool why dont you see if you can get a replacement mandril. i bought mine off car builder sollutions and i got a

replacement from them.

[Edited on 15/2/06 by ditchlewis]

|

|

|

David Jenkins

|

| posted on 15/2/06 at 09:03 AM |

|

|

If you have a lathe, and you're feeling flash, then look at my website under 'Special tools and parts'. Dead easy to make, required

a 50p bearing from a local supplier, takes no effort to use.

Alternatively a HT bolt, a nut and a washer works OK, as long as you use loads of grease to lubricate the nut. The bolt won't last very long,

though.

David

|

|

|

RichieC

|

| posted on 15/2/06 at 09:09 AM |

|

|

Thanks guys. I dont have a lathe so Ill see how I get on with the nut/bolts option

|

|

|

Alan_Thomas

|

| posted on 15/2/06 at 09:29 AM |

|

|

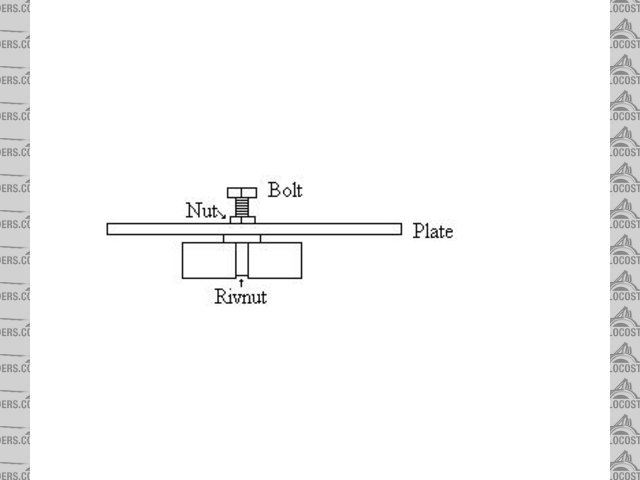

I set all my rivnuts without a tool. using the following.

A piece of strip metal approx 6inch long 1inch wide with a hole of the right size one end (ie 6mm)

Insert the rivnut in position, place the strip over the rivnut then wind a bolt (with a nut already threaded on it) thru the strip and into the

rivnut. Make sure you have fully engaged all the threads of the rivnut.

Then, holding the strip to prevent it turning and hold the bolt head with a ring spanner, tighten the nut. The rivnut is pulled up without damage. You

must stop when it becomes suddenly much more difficult to turn otherwise it is easy to strip out the rivnut thread.

This probably sounds like it needs 3 hands but in practice it is very easy and I used this method to pull up 6,8 and 10 mm rivnuts.

- Alan

|

|

|

RichieC

|

| posted on 15/2/06 at 09:48 AM |

|

|

So something like this then Alan?

Rescued attachment Rivnut.JPG

|

|

|

Peteff

|

| posted on 15/2/06 at 10:26 AM |

|

|

That looks o.k.

Clamp the piece of plate to the bar you're putting the rivnut in with a mole grip and you'll have both hands free to work the spanners.

You could use a big washer instead of plate, put a blob of grease between the nut and plate.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

NS Dev

|

| posted on 16/2/06 at 12:57 AM |

|

|

David Jenkins little tool design is brill, worth finding somebody with a lathe and paying them some beer I'd say!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|