JoelP

|

| posted on 2/1/06 at 08:21 PM |

|

|

strength of a steel tube

hi all. Im building a trailer, and want to work out how strong it will be along its length. The side piece is a mild steel piece of erw, 50x50x3mm

wall thickness. Does anyone know, if it was supported at both ends, how much weight it could have loaded onto the middle before it failed? The piece

is 3.5m long.

With one length down each side, the locost would be the equvilent of 300kgs static, and id estimate that a bump will double that, assuming we arent

going to hit the bump stops on a pair of 750kg suspension units.

The strength will be increase when finished because its will be a box trailer, im just wondering how near disaster i am

Any help appreciated

|

|

|

|

|

Wadders

|

| posted on 2/1/06 at 08:55 PM |

|

|

Hi Joel

a length of 2" box 12' long in isolation is fairly weak if you supported both ends and jumped on the middle it would probably deform, but

in the context of a fabbed trailer, especially a box

configuration i'm sure it will be fine. try to add some triangulation into the design of the sides.

My two wheeled flatbed is only made of 2"x 2" box and angle iron, has no suspension at all and tows the locost with ease.

|

|

|

gazza285

|

| posted on 2/1/06 at 09:01 PM |

|

|

The idea of a trailer is to have the weight supported in the middle, and if the suspension bottomed out you would still have most of the locosts

weight on it's own suspension, so the shock loading would still not be too great. Have you looked a other trailers? The one I used most was made

out of 40x40 angle and looked weak as hell, towed nice though, without any problems, with a complete Escort rally car on it, even towed my old T4

Transporter on it when the engine went bang.

DO NOT PUT ON KNOB OR BOLLOCKS!

|

|

|

flak monkey

|

| posted on 2/1/06 at 09:39 PM |

|

|

Yeah, hang on a sec and I will work it out for you...

David

Sera

http://www.motosera.com

|

|

|

JoelP

|

| posted on 2/1/06 at 09:41 PM |

|

|

i had noticed that most trailers seem to be made of angle iron, but the ones i remember, or saw on ebay, seem to be more like 75mm on the vertical

section.

I guessed it was hard to put a figure to the strength, cos failure would be a sudden affair with the tube folding flat, but it nice to know im not far

off

the box part of the trailer will be designed basically to strengthen the base, and hold ally sheets in place.

cheers for the help chaps

cheers flak, looking forward to some figures! also, what counts as failure in stress analysis, or would FEA just tell you a pound feet per degree?

[Edited on 2/1/06 by JoelP]

|

|

|

Mix

|

| posted on 2/1/06 at 09:47 PM |

|

|

I'm intrigued

How would you design a trailer that would contain a member 3.5m long and supported at both ends??

Mick

|

|

|

flak monkey

|

| posted on 2/1/06 at 09:59 PM |

|

|

Its a while since i have done this, so someone should check it...

For the figures you have given:

The maximum bending moment will be:

M=0.25xLxW (where W=load in newtons and L= length of beam)

So M = 0.25*3.5*6867 = 6008.625Nm

Beam bending equation is:

stress/y(n) = M/I

Where y(n)=distance from neutral axis, M=bending moment and I=second moment of area of the cross section.

In your case the critical stress level will be that of the yeild strength of mild steel, which is around 215MPa.

The second moment of area of a bit of 50mm box section is:

I = (0.05^4)/12 - (0.044^4)/12 = 2.0849x10^-7m^4.

So the bending equation will be most useful as:

stress = My(n)/I

stress = 6008.625*0.025/2.0849*10^-7

=7.2x10^8Pa

Which is 720MPa, just a little over the yeild stress for mild steel!

If you want to know the max weight that the beam can support I will work that out as well.

As for FEA that will give you a saftey factory, if its below one, prepare for failure!

[Edited on 2/1/06 by flak monkey]

Sera

http://www.motosera.com

|

|

|

flak monkey

|

| posted on 2/1/06 at 10:07 PM |

|

|

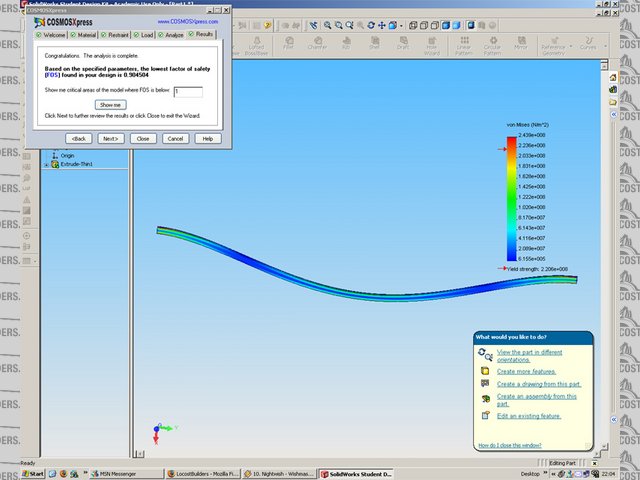

I did it the old fashioned way as I dont have a very sophisticated FEA system. I can only model it as restrained at both end faces with a UDL along

it. But I did it anyway.

Heres the pictoral result...and yes it failed!

Rescued attachment too much.jpg

Sera

http://www.motosera.com

|

|

|

JoelP

|

| posted on 2/1/06 at 10:10 PM |

|

|

quote:

Originally posted by Mix

I'm intrigued

How would you design a trailer that would contain a member 3.5m long and supported at both ends??

Mick

i turned it upside down to simplify the problem into one mass rather than two half masses.  The single mass/force could be regarded as the wheels

reaction to the fixed weight of the locosts wheels. The single mass/force could be regarded as the wheels

reaction to the fixed weight of the locosts wheels.

Cheers for that flak monkey, didnt follow it to be fair but it all looked interesting

|

|

|

Mix

|

| posted on 2/1/06 at 11:12 PM |

|

|

Ah!! now I see

That's some Locost though with a 3.5m wheelbase

Mick

|

|

|

JoelP

|

| posted on 2/1/06 at 11:33 PM |

|

|

thats full nose to tail, to allow it to be a box trailer! in fact, it might be tight  is suppose that adds a bit of leeway in the sums, as the mass

is probably only acting over 2.5m is suppose that adds a bit of leeway in the sums, as the mass

is probably only acting over 2.5m

|

|

|

Peteff

|

| posted on 3/1/06 at 12:11 AM |

|

|

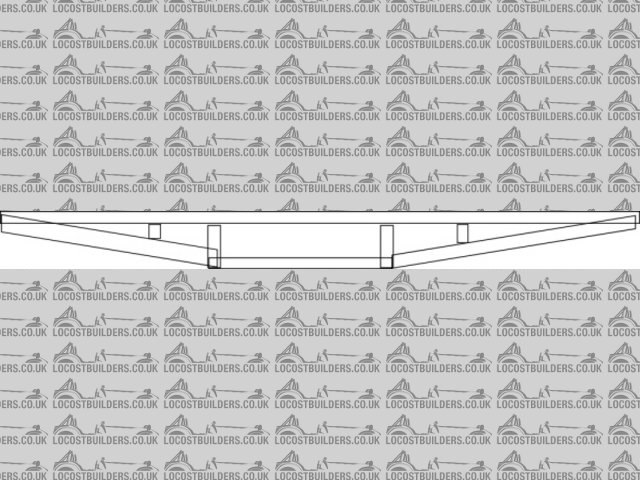

Rough sketch side view

I did one like this ages ago from 50x50 box and it lasted carrying various loads, cars included. Reinforce it where it looks empty and you can't

go far wrong. Plenty of crossmembers and you don't need too heavy a floor or just put wheel runners in.

Rescued attachment base.jpg

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|