James

|

| posted on 24/8/04 at 09:51 AM |

|

|

Making own bellhousing- Discuss

Purely theoretical question as I'm going Pinto to Type9 but I was just wondering on the theoretical possibility of making a bellhousing

oneself.

We often have people asking how to connect engine X to gearbox Y and there's then a list of obscure parts from vans etc. listed. So what about a

DIY job?

Two ways I can think of:

1) Casting it yourself from ali. I've done ali casting at school- wasn't too hard. The worst bit for a home user being sorting out the

melting furnace I guess. The skill then coming in the making of the mould to pour the ali into.

2) A cut and shut made from steel plate: Get the front face from the bellhousing of your donor engine by cutting the 'ring' part of the

bellhousing that bolts to the engine. Then take the back face of the bell from your gearbox donor.

Then, with appropriate use of a jig, join the two together using 5mm steel plates in such a way you get the bell shape you want.

Obviously the clutch lever will be an issue but maybe a hydraulic is the answer.

Anyway, just a thought during a long drive home the other night!

Cheers,

James

|

|

|

|

|

mackie

|

| posted on 24/8/04 at 10:24 AM |

|

|

I would have thought that method 2 was the most common. You'd need access to a milling machine too to do it the first way.

Problems ofcourse arise if one bellhousing is ali and the other iron or steel. Then I guess you can just get a flange lasered up based on careful

measurements.

It'd be interesting to undertake certainly

I'd agree with using a concentric hydraulic clutch release mechanism, adding a great big bulge in the side of the housing would be a pain.

|

|

|

David Jenkins

|

| posted on 24/8/04 at 10:28 AM |

|

|

I'd be concerned about strength - the bellhousing has to resist a hell of a lot of torque (roughly the same as the power being transmitted, but

in the other direction, particularly during initial acceleration - I think).

Any flaws, internal cracks or design weaknesses would result in a VERY interesting experience for the occupants!

David

|

|

|

theconrodkid

|

| posted on 24/8/04 at 10:49 AM |

|

|

i put a york (transit deisel)engine into my landrover,made a bellhousing from 6mm(?) plate and it worked well,just a matter of lining it all up and

having a welder capable of doin the job

who cares who wins

pass the pork pies

|

|

|

locoboy

|

| posted on 24/8/04 at 11:28 AM |

|

|

Im with Dave J here, its subject to a lot of stresses and of course the vibration transmitted to all the components through normal road use is far

greater than in any 'normal' tin top. On top of that you will need very accuarate jigging or machining to ensure it all lines up and

doesnt run slightly out of alignment and put extra stresses on components that are already pretty well loaded.

Good idea in theory though Chris, i though about doing someting like that a couple of years ago. I think if its made out of thick steel plate isnt it

going to have a weight penalty too?

ATB

Locoboy

|

|

|

Jasper

|

| posted on 24/8/04 at 12:11 PM |

|

|

James - you need to get out more

|

|

|

bob

|

| posted on 24/8/04 at 12:16 PM |

|

|

I agrre with jasper,it must be like being on benefit at your place of work or is it called place of shirk

|

|

|

Peteff

|

| posted on 24/8/04 at 12:32 PM |

|

|

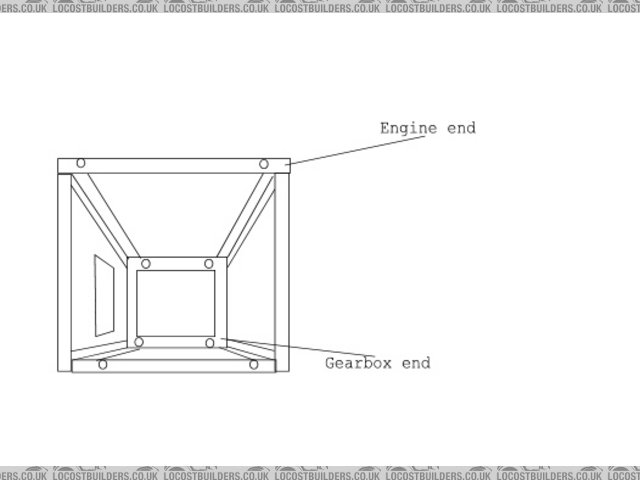

No heavier than cast steel.

I reckon you could make a frame up of 5x25mm strip and angle with the bolt holes in it then seam weld some 3mm plate round the frame to fill it in.

Clutch actuation should be doable using original parts or hybrid hydraulics.

Rescued attachment bellhousing.jpg

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

James

|

| posted on 24/8/04 at 02:15 PM |

|

|

Jasper,

Go play with a Teddy!

quote:

Originally posted by bob

I agrre with jasper,it must be like being on benefit at your place of work or is it called place of shirk

Well put it this way- my three hour lunch break just consisted of an hours Megasquirt reading (and I don't mean anything to do with porn!  )

followed by a 2 hour round trip to the scrappy! )

followed by a 2 hour round trip to the scrappy!

Make of that what you will!

Anyway, must go- time for a cup of tea and a cake!

James

[Edited on 24/8/04 by James]

|

|

|

James

|

| posted on 24/8/04 at 02:19 PM |

|

|

quote:

Originally posted by Syd Bridge

I make 'em out of kevlar for a customer involved in drag racing in usa. Also done them out of carbon. Utmost care needed with fibre position

though.

Syd.

Hmm, interesting.

How does one 'do' kevlar? Lay it up like CF then autoclave to cure it?

Cheers,

James

|

|

|

Surrey Dave

|

| posted on 24/8/04 at 03:51 PM |

|

|

Cushy?

I thought my job was good

WHY do you want to make one when youre using a pinto and type 9?

Do you never want to finish the car?

Conrods idea sounds good ,make a plate to suit the engine and weld it on the front of the different gearbox ,I think some of these adaptors would

even bolt on depending on bellhousing size, and where the bolt centres are exactly.

Just finish the car the quickest easiest way possible then you can drive round in it thinking up lots of great schemes Not to

do.................cheers

|

|

|

James

|

| posted on 24/8/04 at 04:29 PM |

|

|

Dave,

There's a couple of important parts to my post you seem to have overlooked:

quote:

Originally posted by James

Purely theoretical question as I'm going Pinto to Type9

must be all that time spent beating yourself blind over pinkbits.com that's done it!

James

|

|

|

Surrey Dave

|

| posted on 24/8/04 at 05:29 PM |

|

|

Eh?

|

|

|

bob

|

| posted on 24/8/04 at 06:04 PM |

|

|

James

Theoreticaly you are just wasting time

Get in the garage and get on with it,oh and dont come back till you are finished

|

|

|

JoelP

|

| posted on 24/8/04 at 07:01 PM |

|

|

im with the 'can dos' on this, i think it is definately possible. I would take the two bells involved, pick the shortest and make up an

adapter plate (the right thickness) to link the two bolt patterns. overlapping bolts would be skipped or bodged as approprioate. the alignment is the

only problem. i would do something like cut a splined hole in the plate before marking up the bolt holes, then resting it on the input shaft. ideally

the replacement gearbox would have the shorter bellhousing. assuming both gearboxes have the same input shaft dimensions!

|

|

|

David Jenkins

|

| posted on 24/8/04 at 07:53 PM |

|

|

Joel,

Now you're talking about something different - anyone with a reasonable bit of mechanical sense could probably work out an adaptor plate with a

bit of mucking about.

That's not the same as making a whole bellhousing!

rgds,

David

|

|

|

JoelP

|

| posted on 24/8/04 at 08:14 PM |

|

|

well why make a whole bellhousing if the adapter plate would do?! dont tell me, i bet there are some times you cant use an adapter plate...

|

|

|

type 907

|

| posted on 24/8/04 at 08:28 PM |

|

|

Sorry Pete but I'v just got to ask.

Is that a bellhousing from a VOLVO ?

Paul G

Too much is just enough

|

|

|