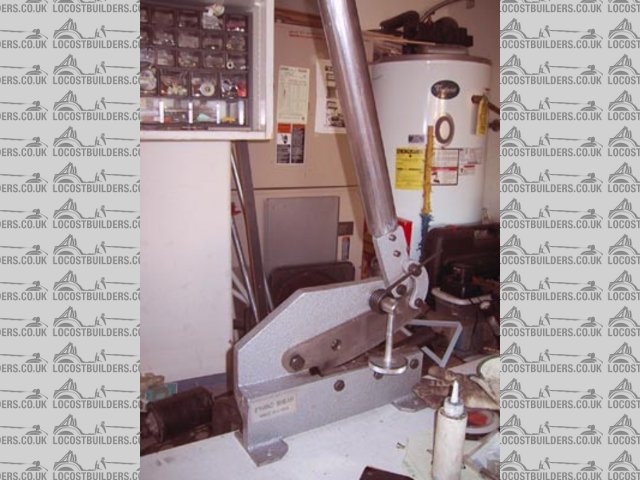

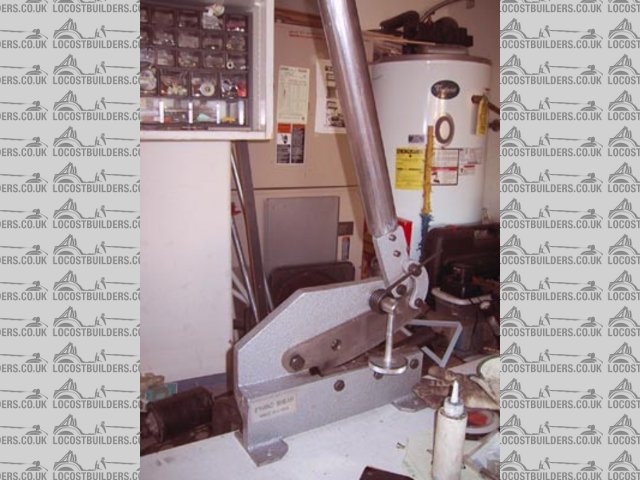

My favorite building tool

Later,

Steve

[Edited on 1/17/04 by sgraber]

I've been using this bench mounted steel shear for a while now. I wonder if any of you guys have discovered how handy this tool is!

My favorite building tool

Later,

Steve

[Edited on 1/17/04 by sgraber]

I used one of those at school a few years back...

Bloody good devices they are..

Steve,

What's the maximum cut thickness? 5mm?

I've seen a few about the 50-80 quid mark.

e.g. http://www.screwfix.com/app/sfd/cat/pro.jsp?id=18642&ts=31218

and machine Mart (http://www.machinemart.co.uk/ranges.asp?g=106&r=2044)

My mate owns a steel stockholders and he's got one that he assures me is "nasty"

Cheers,

Neil.

I've got the screwfix one of those and it happily chew's through ali right up to 8mm (largest size I've put through it so far). great

bit of kit. Only reccomendation is you don't stand under the bar when you pull it down. There's nothing like smacking yourself on the head

infront of the neighbours, does wonder's for your street cred.

Chris

I used to borrow a similar thing from a neighbour years ago. It had a round cutter which advanced when you pulled the handle and you could cut curves

with it. It was brilliant but he flitted and took it with him. It would cut 16g steel, no problem.

yours, Pete.

i was looking at one in machine mart, didnt realise they were that good. Plus my bench is a little flimsy for one, seeing as its the missus' old

dressing table...

[Edited on 17/1/04 by JoelP]

I bought mine from ebay. I think I paid $75.00 for it. Now it appears to be a little over $100. However, I think that if one needs to cut any type of

steel, and you don't have a plasma torch, this baby is indispensable. I added an extension to the handle and now I can cut even thicker material!

Ebay Link 1

Ebay Link 2

What are $ ?

I've never heard of those before... I'm English

I'm currently without one...Did have unlimited access to one but my old employer would insist on me using it for their jobs.So I left.Ha! that'll teach them.Now lelts see how they go on without me having full fabrication facilities..............................Oh bugger.................Dear Santa..Must.Get.Metal.Shear.

we have one of those at work.... 2 limitations

1. its a bit hard to cut anything much over 2mm cos it needs to flex away from the cutting area as you feed th sheet thro, and its not always easy to

keep on line and

2. The rating dont count for stainless - as I found out when I near shagged ours by trying to cut rod with it.

atb

steve

used a propper big metal guilotine when i did my C&G welding course - used it for cutting sheet steel upto 3mm - was fantastic, press button with

foot and boosh, chop clunk clink done - amazing bit of kit, but quite scarry when you think of the power involved in cutting metal like that

Know what you mean - I used to visit a metal supplier in Cambridge for odds and ends, and they had an enormous sheet metal shear. Put the metal in,

stamp on the pedal - crash - metal cut without bending.

The scary bit related to the people employed to use it - have you ever seen that Kellogs cornflakes advert, where they had a gormless bloke who woke

up when he'd had his plateful? Well, the Cambridge blokes were 'pre-cornflakes'.

rgds,

David

I use both types at work. The bench mounted ones are great for cutting short lengths of thin metal, ideal for 16g steel/stainless or 4 mm ali plate. Large industrial hydraulic shear guillotines are good for most metals up to 13mm thick and 3 metres long. Only problem is most people do not have access to industrial equipment and it does have the tendancy to bend the thick metal because of the weight overhanging.

I worked in a boiler factory for a few months years ago and some of the machinery there was antique stuff like fly presses and things with massive

flywheels (Bliss press) but one of the machines (Promecam I think) which was more modern, would cut, punch or bend anything you threw at it with the

right tooling.

yours, Pete

Got one of the screwfix ones for work the other week, nae probs with it..handle is now spring loaded so that when released it goes back up and

doesn't fell you when walking by....well worth the money....

And to go with it is the air pop rivet gun from machine mart...will save you getting forearms like popeye...!!!!!

Think i may have bumped into the guy Dave Jenkins was refering to , but I would like to point out not everyone in Cambridge is gormless , some of the locals, if you can find one, are o.k. Rusty

I wasn't generalising about Cambridge - this bloke was unique (except for his similarity to the cornflakes guy). How can I describe him...

vacant expression, dragged his knuckles as he walked, one eyebrow (across both eyes).

I'd better not mention the name of the metal merchants - I might need to buy more stuff there!

rgds,

David