Tube bending help.....

number-1 - 5/10/19 at 02:32 PM

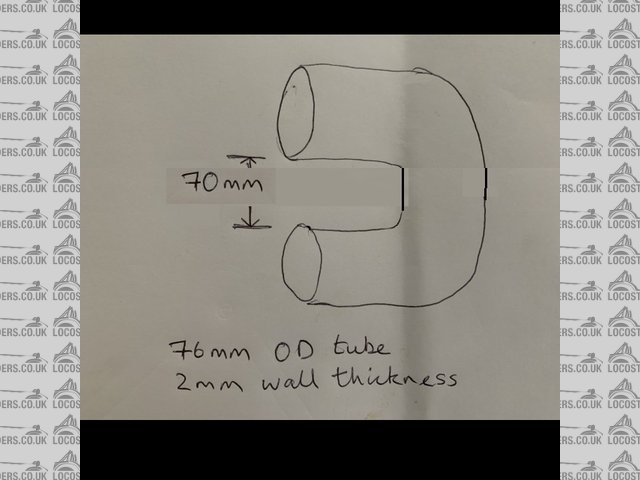

Can anyone point me in the right direction to get a bit of tube bent for between a supercharger and an intake plenum? Its not an off the shelf

dimension and needs to be in metal

76mm OD tube with 2mm thick walls (can be 3 if easier?), legs can be 15cm long but no longer, however, this is where it gets tricky as i need it to be

7cm from the top of the bottom leg, to the bottom of the top leg...if that makes any sense??? I will get a picture uploaded to make it clearer.

Anyone got any ideas? I cant weld so making something isnt an option and silicone hose isnt suitable.

Cheers

N1

[Edited on 5/10/19 by number-1]

nick205 - 5/10/19 at 02:49 PM

Don't know about tube bending, but it looks a pretty tight bend to me. Might be something you need fabricated for you from 2 or more sections.

number-1 - 5/10/19 at 02:52 PM

Hello mate,

Yeah thats what i thought too. Maybe x2 90 degree elbows cut down and left with 3.5cm on each joining leg?

Its probably a simple thing to do if i knew how to weld

nick205 - 5/10/19 at 03:33 PM

It seems like something an exhaust fabricator could make for you in stainless steel tube.

mark chandler - 5/10/19 at 03:57 PM

That,s a really tight radius, tube bender is the person to call

https://tube-bender.co.uk

He will tell you what's possible, if he cannot get it that close you will need to get a bent section off him as close as possible and then have

someone slice it and weld it to tighten up.

40inches - 5/10/19 at 03:57 PM

The tightest bends I have seen are 1.5 the tube diameter.

LINK

J666AYP - 5/10/19 at 04:23 PM

With a radius that tight I would get two 90's and weld them.

rf900rush - 5/10/19 at 06:51 PM

May be worth trying to look for donuts

may not be the correct size but may help the search

eBay Item

https://www.ebay.co.uk/itm/INTERCOOLER-PIPE-MANDREL-BEND-Mild-Steel-3-5-360-DEGREE-DONUT-SEAMED/223062979897?hash=item33ef96f539:g:arAAAOSw9-ldkEVS

gremlin1234 - 5/10/19 at 07:20 PM

I think the original pic is somewhat confusing,

it mixes cm and mm as units and seems to draw it much tighter than required

a slightly closer to scale, without mixed units might be

Description

Simon - 5/10/19 at 07:39 PM

Two of these

https://www.allstainlessltd.co.uk/nominal-bore-fittings/nominal-bore-schedule-10-90-deg-weld-elbow-to-ansi-b16.9-316

or

https://www.allstainlessltd.co.uk/nominal-bore-fittings/nominal-bore-schedule-40-90-deg-weld-elbow-to-ansi-b16.9-316

or

https://www.allstainlessltd.co.uk/mandrel-bends-and-tube-for-exhaust/hygienic-90-deg-bend-316-to-bs4825-part-2-1D-polished

welded together

[Edited on 5/10/19 by Simon]

coyoteboy - 5/10/19 at 11:53 PM

99% sure that's too tight to bend. Maybe a cast part might work, welded together.

Angel Acevedo - 6/10/19 at 05:14 PM

I´d go for Pie-Cutting from appropriate material and sending to welding shop.

As a lot of the labor goes into cutting, dressing and fitting, cost may be reduced substantially...

HTH.

WallerZero - 7/10/19 at 06:14 AM

You need an 73mm centreline radius (to hit your 7cm (70mm?? Don't mix units lol). If you find some place that can do that, and not break the bank

of a hobby project, let me know, it would probably get me a promotion at work! Haha. Basically its not a normal bend radius so would need specific

tooling to do = ££££.

Best option imo would be 2x 90 degree bends and some fabrication work to achieve your part

[Edited on 7/10/19 by WallerZero]

pewe - 7/10/19 at 05:29 PM

Try Rich's Fabrication Shop in Abingdon on faceache.

He seems an all round top welder and does lots of one-offs.

HTH.

#Cheers, Pewe10

907 - 7/10/19 at 08:09 PM

quote:

Originally posted by Simon

Two of these

https://www.allstainlessltd.co.uk/nominal-bore-fittings/nominal-bore-schedule-10-90-deg-weld-elbow-to-ansi-b16.9-316

or

https://www.allstainlessltd.co.uk/nominal-bore-fittings/nominal-bore-schedule-40-90-deg-weld-elbow-to-ansi-b16.9-316

or

https://www.allstainlessltd.co.uk/mandrel-bends-and-tube-for-exhaust/hygienic-90-deg-bend-316-to-bs4825-part-2-1D-polished

welded together

[Edited on 5/10/19 by Simon]

2 off of the 3rd one down, cut the straight bits off (+3mm) and weld together.

Paul G

motorcycle_mayhem - 7/10/19 at 08:30 PM

I fabricated mine from 'Donuts'.

Available from most outlets, e.g. Merlin where I bought mine (I have no connection).

You might be able to bodge a silicone hose onto a half-cut donut, but not something I'd even try (I weld things).

Camber Dave - 8/10/19 at 07:44 AM

For something that tight, I would make a hardwood former and form it as two sides from flat sheet.

Though at 2mm it will need to be annealed so oxy-acetylene or propane will be needed.

Even so it could be difficult to weld in the middle.