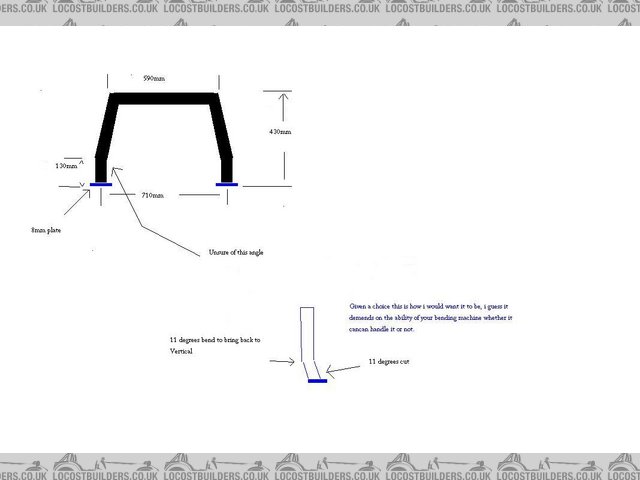

The angle that forms the kink in the vertical leg and the angle that takes it to horizontal.

Can anyone help given the dimensions already on the drawing?

bar

Cheers

Colin

Guys i need to work out the 2 unidentified angles in the drawing below.

The angle that forms the kink in the vertical leg and the angle that takes it to horizontal.

Can anyone help given the dimensions already on the drawing?

bar

Cheers

Colin

What size pipe?

168.7 degrees, if my trig serves me right

HTH's

[Edited on 14/1/10 by omega0684]

57.15mm

Cheers

quote:

168.46 degrees, if my trig serves me right

I worked it out in AutoCAD to 166.1 degrees. I guessed the object as being 25mm box section. So I'm probably miles out

171.82 degrees is my answer

There are 2 angles though...............

quote:

Originally posted by omega 24 v6

quote:

168.46 degrees, if my trig serves me right

Not quite as you need the pipe diameter first.

OK so overall bottom width is 710 plus 57.15

equals

767.15

Minus the top size of 590

equals 177.15

divide by 2 to give base of triangle

equals 88.575

Tan of angle = opp/adj

so 300 ( 430 -130) divided by 88.575

equals 3.387

so inv tan equals 81.72 and then add the 90 degrees

equals 171.723

quote:

no you dont, all you need to do is work out tan^-1of 0.2 and then minus that from 180. from his drawing it takes the pipe diameter into account from the bottom measurement. (as he has put his marker in the centre of the tubes)

quote:

There are 2 angles though...............

I made it 163.55 degrees. I make arctan 3.3869 to be 73.55

quote:

Originally posted by mattf

I made it 163.55 degrees. I make arctan 3.3869 to be 73.55

quote:

I made it 163.55 degrees. I make arctan 3.3869 to be 73.55

Your way above me guys!

so the 2 angles will be???????

163.55 for the vertical angle ( the one you marked as unknown). And 106.45 for the other one

OOOPS didnt see your post giving the Dia so see below:

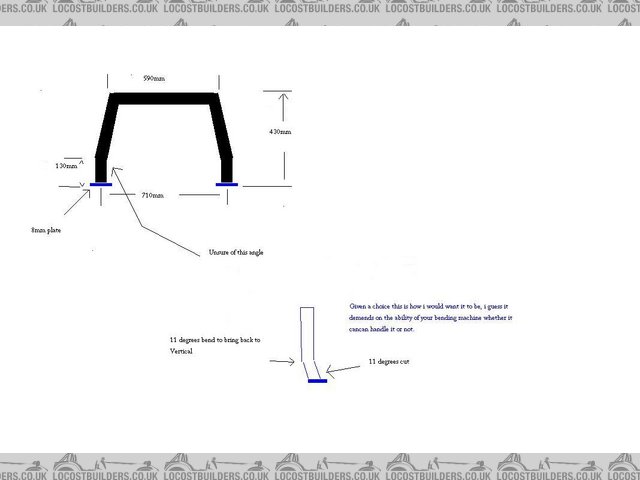

Rescued attachment AngleQuery.gif

quote:

Originally posted by mattf

I made it 163.55 degrees. I make arctan 3.3869 to be 73.55

beaten to it ..... should be tan c = ... in the above ... oops!!!

.... and then 300/88.75

[Edited on 15/1/10 by 02GF74]

Awsome,

Thanks a lot guys, It has helped me out of a bit of a sticky situation.

The power of LCB comes to the rescue again

Don't forget that if this is being done on a "programmable" bender, you will have to include an element of over bending to allow for spring back.