Phoenix chassis advice

ArAKern - 18/8/17 at 08:28 PM

Hello All

I have a very early STM Phoenix with a box section chassis rear irs and running sierra uprights.

The car was IVA earlier this month failed but nothing chassis related but i have some concerns / questions.

Chassis strength:-

The box section wall thickness seams a little thin (I managed to dent it when trying to stamp in the chassis number and also crush a section when

jacking it up in a hurry without a wooden spreader) As i am running a v6 and not a bike engine should i be adding any strengthening ?

Suspension pickups:-

how accurately should the mounts match each other N/S to O/F some of mine are 2-3mm different is this normal?

A-arm mounting:-

most of the chassis mounts are just bent flat bar sections that need 2-3 shimms/washers to take up the slack around the A arm bush

but how tight should this be? (my thinking is you do not want to pinch the outer tube of the suspension bush or the inner crush tube)

I have just been tightening the bolts then backing them off till the arm moves freely.

Front upright mushrooms:-

Now this gives me the most concern the mushrooms are a small section of tube with a thread to take a lower ball-joint the tube is only about 1/3 the

length of the upright section with just the std pinch bolt holding it. (does the raw phoenix use the same item) I cannot use the MK indy mushrooms

without serious modification to the top rocker suspension arm what have others done?

As the STM came with no build manual does anyone have the geometry setup figures for it (caster camber trail etc)

Many thanks

watsonpj - 19/8/17 at 10:19 AM

I thought the phoenix was the same chassis pretty much as the fury so it should be fine from a strength point of view. There's been some v8 cars

built atheist one on here maybe they can say if they strengthen their chassis.

On chassis mounts do you.mean out of position (up/down left/right) or across the gap?

On the suspension assuming they are a poly bush the outer should be free to move but with minimum clearance you can engineer in. The crush tube

should be tightened held firmly and act as a Pivot.

Don't know about the last two questions sorry.

Cheers Pete

HowardB - 19/8/17 at 11:37 AM

the Fury manual is available as a down load, that might help, otherwise worth asking on the JPSC forum too,..

ArAKern - 19/8/17 at 12:11 PM

"On chassis mounts do you.mean out of position (up/down left/right) or across the gap? "

yes and yes. for example the top forward mount of the A-arm on the N/S rear is 0.5mm smaller accross the gap but is it 2mm further reward and 1mm

lower that is counter part on the O/S.

I realise that these are not mass produced chassis and the gig was probably made from ply and wood, but is this amount of tolerance normal?

Thanks will try and find a download for the Fury

procomp - 19/8/17 at 01:15 PM

Hi.

Is it actually an STM Chassis or a JPS chassis. STM chassis where round tube and built purposely for racing and had raised pickup chassis mountings

to lower car to a 75mm ride height at front.

I've done a lot of work and development on the STM chassis over the years and not seen a square tube version. However if it is a genuine STM it

will more than likely be in 18 Guage material so the chassis will dent more easily if abused.

If needs be i can contact Ian as we are still in regular contact.

Cheers Matt

peter030371 - 19/8/17 at 01:47 PM

The Phoenix is a full bodied Striker and thus slightly smaller in a few areas to a Fury.

This is very old but may help a little http://www.striker-cars.co.uk/wp-content/uploads/StrikerManual.pdf

As to some sides being 2mm out from one side to another.....you may have a good chassis then  These cars really need fully adjustable suspension so

you can square it all up once built

These cars really need fully adjustable suspension so

you can square it all up once built

ArAKern - 19/8/17 at 02:02 PM

Hello Matt

The kit was purchased by me from Ian back in 2003 at the time he was very excited about the round tube race chassis he had in development.

but as far as I know this was/is a STM chassis. (but could have been old stock from JPS? sorry do not know the history of the phoenix chassis)

The ride height is around the 120mm mark but needs to drop a little in the front i believe.

Do you have any geometry setup figures for it (caster camber trail etc) road going

obfripper - 19/8/17 at 05:10 PM

quote:

Originally posted by ArAKern

A-arm mounting:-

most of the chassis mounts are just bent flat bar sections that need 2-3 shimms/washers to take up the slack around the A arm bush

but how tight should this be? (my thinking is you do not want to pinch the outer tube of the suspension bush or the inner crush tube)

I have just been tightening the bolts then backing them off till the arm moves freely.

The crush tube needs to protrude 0.2-0.5mm past the nylon bush at one end, try to aim for the smallest gap without impeding free movement of the arm

when tightened. A couple trial fits may be required to get this right.

Any gap between the chassis and the crush tube when trial fitted should be shimmed with washers(with the same od as the bush) to take up the gap,

otherwise tightening the bolt will cause an unwanted load on the chassis.

The crush tube and flat faces of the bush want greasing, moly cv grease works well but is messy, lm grease tends to dry out and cause some stiffness

in the pivoting action. The nylatron bush used is self lubricating but without grease the crush tube will corrode and go stiff.

The bolt then needs tightening 80-90nm to clamp the crush tube. If it is loosened, the upper suspension arm will just pivot on the bolt instead and

wear away the chassis fixing points.

The geo settings are going to be the same as a sierra based irs striker as the square tube chassis is shared with the irs striker.

There are some more useful bits on the old sylva website using archive.org to browse, the later captures lose the striker/phoenix content.

Eg. https://web.archive.org/web/20010519152444/http://www.sylva.co.uk:80/

Dave

procomp - 19/8/17 at 05:13 PM

That will be an as per JP chassis then possibly with a few little mods here and there.

As mentioned above ignore Fisher Fury dims as it was not the same chassis in all areas.

The basics for what you want are Camber -2Deg, Caster 4 - 4.5 Deg, Toe For road usage 0.5 - 1mm in Max.

The biggest issue you may have is selecting spring poundage for front due to inboard dampers. Most get lost as the damper will be wrong for

application and not allowing spring to operate freely. But start with 200 - 225Lb Max on front. If not feeling predictable or smooth at front then see

about sorting dampers as thats where the issues are found. Above setting should give good results.

Tolerance on brackets Etc 2mm is considered good in the kitcar industry most manufacturers struggle to get withing 10mm. !!!

SPYDER - 19/8/17 at 07:10 PM

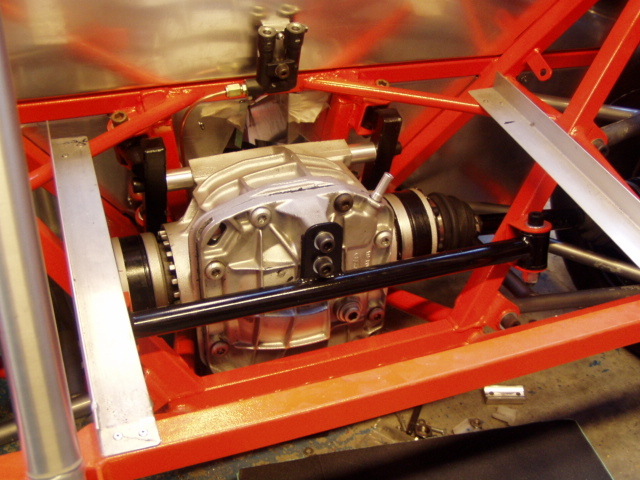

I have a 2005 round tube chassis Phoenix Fireblade. The chassis was purchased from Ian when he was winding up STM. We were lucky enough to get setup

advice from our friend Tim Gray, a man who knows a bit about the Phoenix. He suggested 250lb springs all round. The front suspension settings he gave

us won't be much use to you as we have STM fabricated uprights which were based on Capri geometry IIRC. He did tell us to leave the front alone

once set and make any handling adjustments to the rear only.

Tim had broken the rear suspension pickups on his car more than once and advised us to beef up those areas. We added cross bracing to a number of

places, in particular around the diff. Plenty of pics in my archive. Nothing has broken, so far.

procomp - 19/8/17 at 08:23 PM

250Lb springs all round was for pure race useage when using the anti roll bars i developed for Ian and the works car Tim raced.

Would not be suitable for the JP chassis or road use.

Cheers Matt

ArAKern - 19/8/17 at 10:36 PM

Will take a look at spring rates in the morning defiantly feel they are not correct

As the rear seams to have some travel and the front is rock solid even with my 16 stone bouncing on the front rail.

Matt thanks for the setup info can i assume toe in is the same for front and rear?

Dave thanks for the description on mounting the A-arms. But how stiff should the feel when bolts are tightened correctly?

will take some photos in the morning but my rear lower and upper arms feel very stiff the bushings are not like a power flex item with 2 bushes pushed

into the tubes and a free floating crush tube, I believe they are all one piece item but will check (it was 14 years ago when i installed them  )

)

Thanks to all for the help so far

Giles

obfripper - 19/8/17 at 11:46 PM

Do you know if the nylatron bushes inner bore was reamed to match the od of the crush tube?

As supplied they were more of an interference fit and need reaming to give a clearance fit, before any grease etc is applied.

The crush tube should turn freely by hand in the bush when the clearance is sufficient.

I did think the irs rear wishbones used the same pressed in metalastic bushes as the live axle trailing arms,leading arms, panhard rod and front lower

wishbones. These require tightening once the vehicle is in running position with correct ride height, they have limited angular movement and are

fairly stiff in that movement.

The nylatron bush material is grey in colour and far harder than a powerflex bush.

Hopefully your pics can shed some light on your setup.

Here are the original sylva instructions for the front upper arms, with some more tips on setting up the arms.

https://web.archive.org/web/20020609152542/http://www.sylva.co.uk:80/bolts.html

Dave

ArAKern - 20/8/17 at 02:43 PM

Dave

yes you are correct here is photo of a bush all are the same front and rear except the rocker arms

and as to the nylatron bushes being reamed I had/have no idea they were fitted as supplied. (In my ignorance and no build manual to state

otherwise)

suspension bush

I have re-torqued the suspension bolts for this week and will strip and rebuild after the IVA retest Friday.

But as i have your attention  on the rear lower arm i have a rose joint I assume for setting toe-in but the top and rear mount are fixed bushes so

on the rear lower arm i have a rose joint I assume for setting toe-in but the top and rear mount are fixed bushes so

how does this work? are you just distorting the bushes?

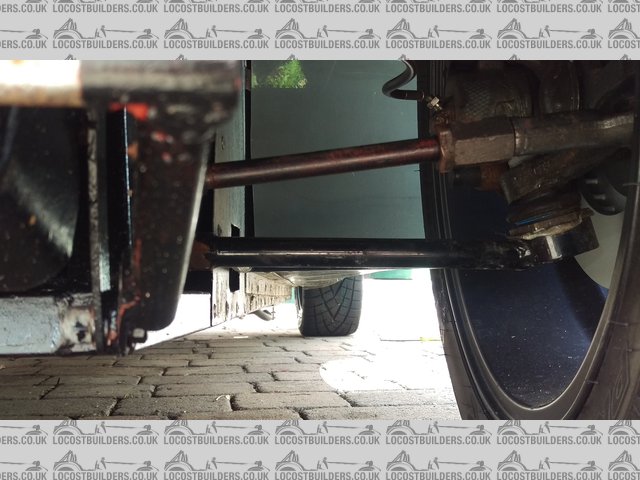

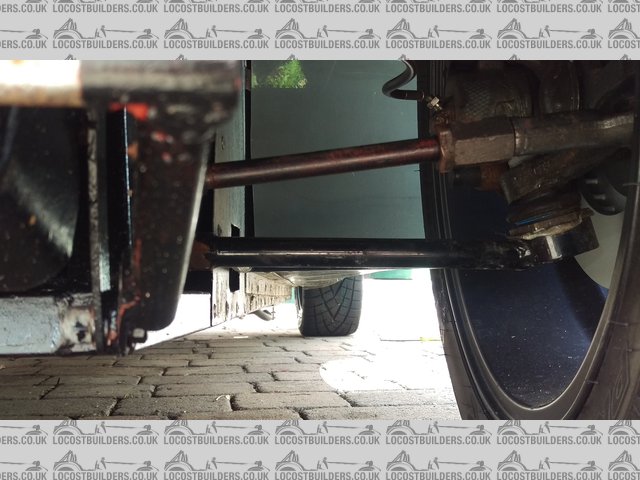

rear suspension rose joint

rear suspension lower mount

rear suspension top mount

NOW my biggest concern is the front uprights mushrooms.

sierra upright

mushroom sierra upright

The second photo shows the mushroom is only 1/3 the length of the upright clamp and is only being held by the STD pinch bolt.

This cannot be right! does anybody supply a better item?

Still need to check on spring rates on the front the rears are marked 200.

when i get round to setting up the car should i raise the steering rack also? (assume car will suffer from bump steer?)

steering rack

[Edited on 20/8/17 by ArAKern]

obfripper - 20/8/17 at 04:12 PM

If the front nylatron bushes were supplied fitted there is a good chance they have been reamed to operate correctly already. Sylva supplied them loose

to fit and adjust yourself.

I thought you had issue with them due to the lack of suspension movement at the front of the car. An easy check is to jack the front end, unbolt the

shock and lift the wheel up and down, checking for smooth movement.

The bushes on the rear suspension will deflect slightly when you adjust the toe-in, this is fine.

The mushroom insert does look short, but should be clamped adequately by the upright pinch bolt, someone with a sierra based

striker/phoenix/fury/stylus should be able to confirm if this is correct.

I have a feeling that your rack mounts are in the position for mk2 escort uprights, some early irs strikers were like this.

Have a look at this thread for some more detail in what you need to do, unfortunatly photobucket has messed up all the useful photos.

https://jpsc.org.uk/forum/viewtopic.php?t=307

Dave

procomp - 20/8/17 at 07:47 PM

Rear toe can vary from 1mm - 2.5mm toe in. Whats important at the rear especially with it being a short wheelbase car car is the thrust alignment.

Its more important to have that as close to zero as possible rather than worry about 1.5 or 2 mm toe. Rear camber set at 0.5deg and then see what

tyres look like after some decent running time. Different driving styles Hard or gentle will dictate more or less from there.

Front too stiff, as mentioned above remove top damper bolt to check if the suspension if free to move those top rocker arm pivots are a nightmare. If

all is free it will possibly be dampers not able to drop soft enough on adjustments or obviously springs but should still move even with 300lb

fitted.

To give you an idea of moment you should be getting Heres the video of the latest development of front suspension i do for the JP ST Phoenix strikers

and AB Arions.

https://youtu.be/oTbVYaUZVno

These cars really need fully adjustable suspension so

you can square it all up once built

These cars really need fully adjustable suspension so

you can square it all up once built

)

)

on the rear lower arm i have a rose joint I assume for setting toe-in but the top and rear mount are fixed bushes so

on the rear lower arm i have a rose joint I assume for setting toe-in but the top and rear mount are fixed bushes so