beagley

|

| posted on 19/4/11 at 06:50 PM |

|

|

More Alibre Parts Finished

I've been continuing to work in Alibre Design trying to copy the "Book" dimensioned chassis just to help myself learn. Progress is

SLOW, but thats probably because I can only devote about an hour a day to it over my lunch breaks. Over the past month I've gotten several

parts done. I first worked on a manifold to teach myself some things. I posted pictures of it when done, but to protect your eyes I won't do

it again.

I've finally learned how to draw a tube rail and extrude the bosses to make actual parts and then bring those parts together into an assembly.

I'm only on page 37 of Chris Gibbs's book. Plus I wanted an exuse to try out the new tag that was put into the web site today.

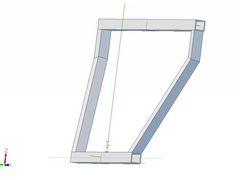

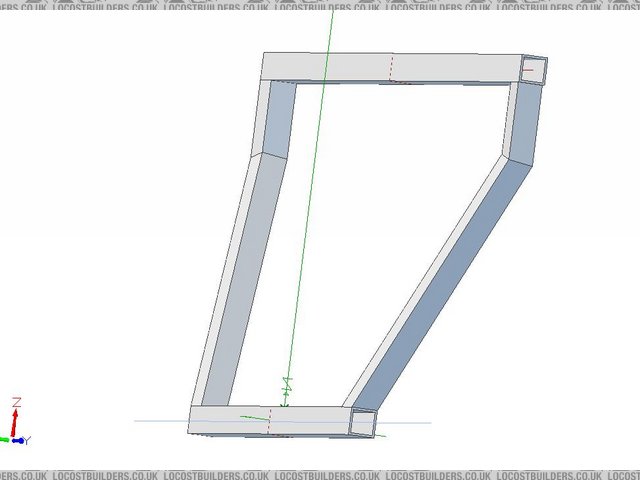

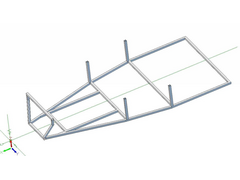

Front Frame for the radiator:

Locost Front Frame

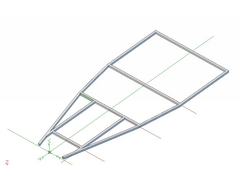

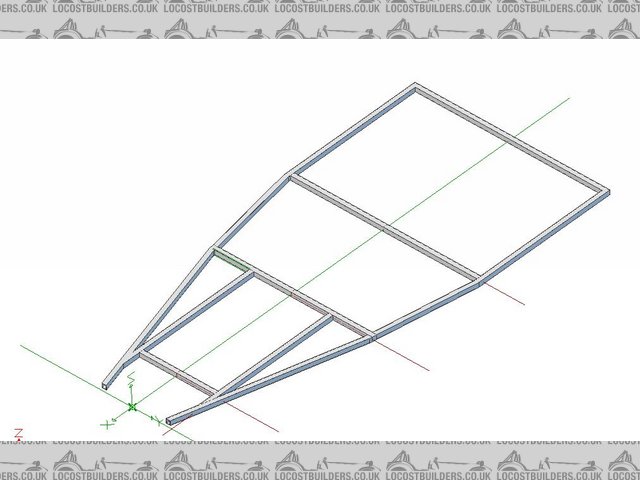

Chassis Bottom Rail:

Chassis Bottom Rail

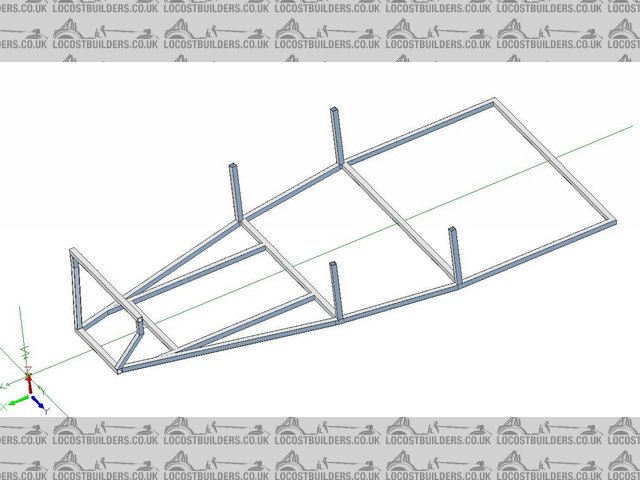

Chassis Assembly Object (this is what I have built and assembled thus far)

Chassis Assembly - 20110419

Please remember that I'm not an engineer, just a computer geek. I know these are basic and simple parts, but nothing beats teaching yourself

and I'm happy to see a sliver of progress.

Beags

[Edited on 4/19/2011 by beagley]

[Edited on 4/20/2011 by beagley]

I'm not scared!!! I'm just marking my territory.

|

|

|

|

|

Kwik

|

| posted on 19/4/11 at 07:41 PM |

|

|

thats looking good.

how is it done on alibre, as i only use solidworks im not familiar with other packages.

on solidworks, you just need to draw the lines of where you want the pipe or tubing, click on a button then click all the lines....

|

|

|

beagley

|

| posted on 19/4/11 at 07:51 PM |

|

|

quote:

Originally posted by Kwik

thats looking good.

how is it done on alibre, as i only use solidworks im not familiar with other packages.

on solidworks, you just need to draw the lines of where you want the pipe or tubing, click on a button then click all the lines....

Thanks for that. It was difficult to grasp at first, but having to think and work in multiple planes is starting to make more sense to me.

It sounds like its similar to SolidWorks but not quite as easy (at least for me). Take the bottom rail for instance I had to draw the outside path

that I wanted the tubing to follow. Then on the 2d plane where the end point of that path is I had to draw the shape that I wanted. It could be

round tubing, square, diamond shape, pretty much whatever to extrude sweep a boss in that shape along the path you defined. Then I had to change my

starting plane to draw a cross member and extrude it to the face of the outside rail. Its hard to explain, but I'm sure like most things that

it just kinda comes with use.

Its frustrating that I only have such a short time to work on it. Seems that once I find a groove its time to get back to my day job. I'm

looking at this as a way to help me understand the chassis and possibly design/fab my own parts if needed.

I'm not scared!!! I'm just marking my territory.

|

|

|

Kwik

|

| posted on 19/4/11 at 07:59 PM |

|

|

it helps with putting things in perspective.

you can do the same thing on solidworks and you can use it to make springs etc.

the weldments (which is the clicking tool) has made life a lot easier, and i could draw 3/4 chassis in an afternoon...

if i used the boss sweep method like you i could be there all day. is there a way of you copying the profile you want to boss sweep instead of you

having to draw it each time?

also once you have drawn the chassis you might be able to download more common parts like wheels and stuff... will speed up your model a lot

quicker.

good luck

|

|

|

beagley

|

| posted on 19/4/11 at 08:06 PM |

|

|

Yeah, I'm sure there has to be a much quicker way to do tubing but as of yet I'm still just dipping my proverbial toes in the water. I do

know that I can download specific parts and use them without having to re-draw them which will save me a lot of time once I get to that point.

There is a forum that the company put up for the users to share information which has helped alot a couple of times, but mostly its just been trial

and error.

I am able to do helical geometry fairly easily (according to the forum) as its basically a wizard that you go through to set up your basic shape. The

thing that I really like about Alibre is that its all parametric. I was working on my assembly earlier today and noticed that I had a funny notch in

the back rail of my chassis cross member. It was due to a constraint that I forgot to add when I was making it. I made the change to the part file

and it cascaded down and automatically pushed the change into any assemblies that were using it.

I'm not scared!!! I'm just marking my territory.

|

|

|