coyoteboy

|

| posted on 12/3/14 at 12:51 AM |

|

|

It is isn't it, I'm still not decided as to whether it's a good thing or not!

|

|

|

|

|

ed1801

|

| posted on 12/3/14 at 07:26 AM |

|

|

Did you consider two turbos in series? You could make one small enough for instant spool and full boost at low revs with the larger taking over higher

up the revs. It might be less technically challenging.

|

|

|

coyoteboy

|

| posted on 12/3/14 at 09:30 AM |

|

|

I did, but it's more technically challenging IMO for less interest for me. I don't want to start hacking the exhaust system which works

just fine and all the twin sequential turbos I've seen have exhaust bypasses in there too (because the small one becomes restrictive to both

intake and exhaust) which seems even more complex! Leaks and problems with intake pipework are somewhat easier to deal with than welding up and

finding leaks and problems with hot gasses.

[Edited on 12/3/14 by coyoteboy]

|

|

|

froggy

|

| posted on 12/3/14 at 05:01 PM |

|

|

Sounds like an m45 to me which is too small for your engine . If the rotors are around 4" long its an m45 . I started with an m45 but changed to

an m62 after wrecking the 45 . Does the Merc unit have a large pwm bypass solenoid around 40mm on it ?

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 12/3/14 at 07:22 PM |

|

|

It is an m45 but it is well within its flow specs and Max rpm in "base" configuration (Its used to push higher boost on a 1.8 normally,

but also used on several larger engines), it's pushing towards the less efficient end but still within design limits to achieve half a bar gauge

min according to their compressor maps and their technical help providers, once I introduce boosted inlet pressure I'm off the known radar but

providing I keep temps low there's no reason for problems. I will see how the 45 goes initially because I will almost definitely struggle to fit

the extra length of a 62 (it was my first target but not convinced its necessary). Don't forget I'm not needing the s/c to push full

pressure alone, I'm compounding.

As I say, looks to have a bypass in the region of 50-60mm, maybe a bit less depending on the housing size, I've not fully stripped it yet.

You've sure broken a lot of stuff by the sound of it!

[Edited on 12/3/14 by coyoteboy]

|

|

|

froggy

|

posted on 12/3/14 at 09:03 PM posted on 12/3/14 at 09:03 PM |

|

|

Talk is cheap , il wait for some pictures .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 12/3/14 at 10:30 PM |

|

|

No problemmo, will be a little wait while I finish my mill conversion to cnc so I can knock up some suitably stiff bracketry and get the rest of the

engine rebuilt but I will post back to this thread when it's a bit further along! And again after I need another rebuild

[Edited on 12/3/14 by coyoteboy]

|

|

|

coyoteboy

|

| posted on 17/3/14 at 10:46 PM |

|

|

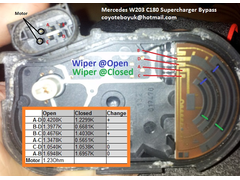

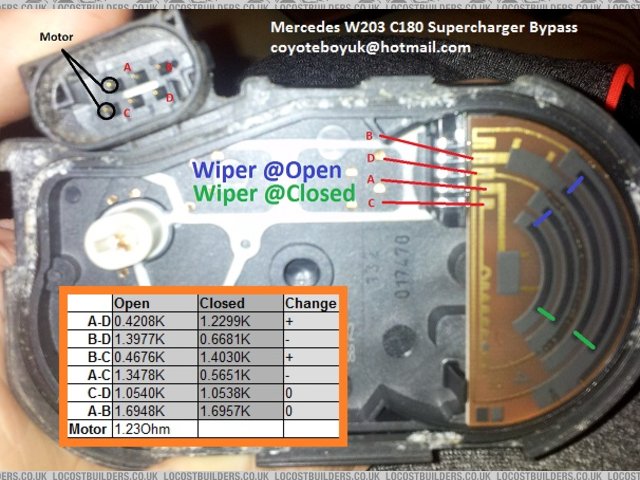

Slight update - the C180 electronic bypass is 56mm diam at it's narrowest point, seems to be "normally open" with one hell of a

spring.

|

|

|

coyoteboy

|

| posted on 18/3/14 at 11:56 PM |

|

|

FYI

Eaton Supercharger Bypass

|

|

|