Trailer project questions

sdh2903 - 29/9/10 at 06:21 PM

Hi all.

A while ago I got this cheap as chips to use as a base for lugging my gkd around:

Description

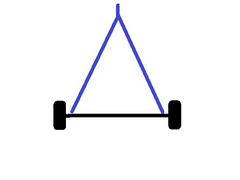

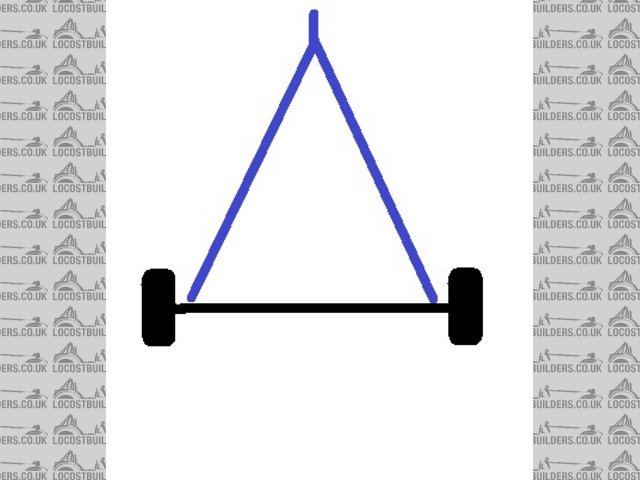

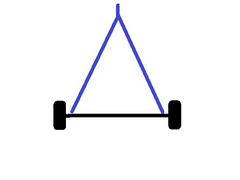

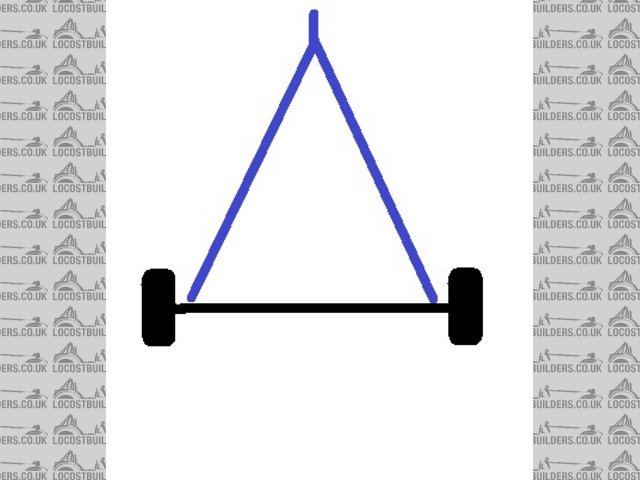

I am going to remove the whole bed as it is 3-4mm steel treadplate and the back end is sagging due to lack of support. The main construction is like

this:

Description

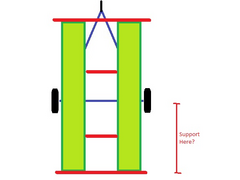

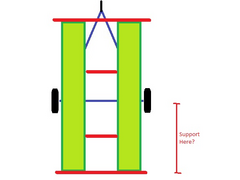

My plans are to end up with something like this:

Description

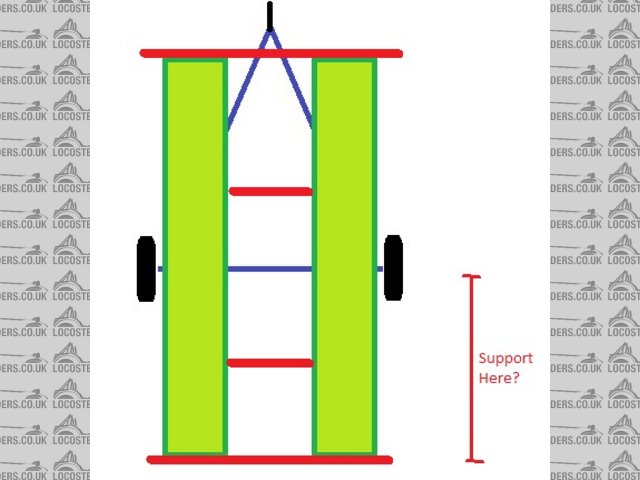

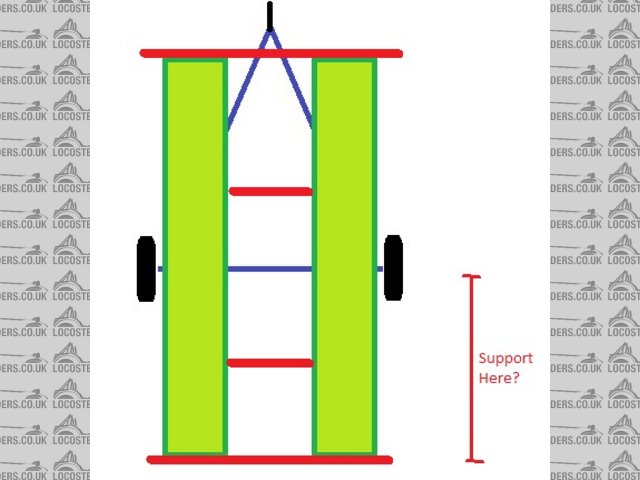

My only concern is lack of support after the back axle to stop it sagging, especially as I will be storing the car on it.

The runners/channels will be mild steel 3mm thick folded or 4mm if needed.

The support i'm worried about is as below:

Description

Any thoughts opinions welcome!

Steve

franky - 29/9/10 at 06:33 PM

has it got suspension units? what about adding a support from the rear down to where the axle is? forming a triangle? Also add some feet front and

rear to support it when using it for stowage?

sdh2903 - 29/9/10 at 06:39 PM

quote:

Originally posted by franky

has it got suspension units? what about adding a support from the rear down to where the axle is? forming a triangle? Also add some feet front and

rear to support it when using it for stowage?

Yes it has braked suspension units, I was thing of adding the rear support as suggested, however i can only weld or bolt them to the axle end on. So I

dont think there would be much strength gained.

The feet are a good call. I would prefer it to be strong enough not to bend at all tho! Saying that the car isn't exactly made of lead!

cosmick - 29/9/10 at 06:40 PM

I have built my own trailer and used 3mm flat galvanised sheet folded into a channel very similar to what you show in your second photo. The sag (or

lack of)that you are concerned about comes from the shape of the channel and will not need support rearwards of the axle if it is made like the

channel in the photo. If you look at the galvanised trailer, you will see that it has no support either. So, if you can find someone locally who can

fold the material into the shape, you will be ok.

sdh2903 - 29/9/10 at 06:48 PM

Cheers cosmick, just what i wanted to hear!

The channels are to be of similar profile to the ones on the galvanised trailer In 3mm steel, then 4mm for the ramps.

cosmick - 29/9/10 at 07:08 PM

If your not putting a traction engine on the trailer, then 3mm ramps will be fine.

The important strength comes from the profile of the channel. If you have about 50mm wall height and a fold at the top of about 20mm then folded again

down by about 20mm to lose the sharp edge this will be strong.

I found a place that could fold 3 metre lengths in one piece. the result is a very professional looking trailer and all for under £350 including new

tyres , mudguards and ramps.

rallyingden - 29/9/10 at 07:11 PM

One other key thing to remember are corner supports to use while loading. Once car is on load is spread better.

RD

sdh2903 - 29/9/10 at 07:12 PM

Have you got any pics by any chance ?

Cheers

Steve

norfolkluego - 29/9/10 at 07:42 PM

quote:

Originally posted by rallyingden

One other key thing to remember are corner supports to use while loading. Once car is on load is spread better.

RD

+1 to that, don't forget it should always be loaded heavy end nearest the tow hitch so when the cars on it most of the weight will be over the A

frame

sdh2903 - 29/9/10 at 07:43 PM

quote:

Originally posted by rallyingden

One other key thing to remember are corner supports to use while loading. Once car is on load is spread better.

RD

Are the simple drop down stands ok or is it better to have the wind down jobbies?

cosmick - 29/9/10 at 07:46 PM

I can email a photo. You have U2U

sdh2903 - 29/9/10 at 07:58 PM

Got the pics, good job with the trailer

cosmick - 29/9/10 at 08:09 PM

I am sure you can do something very similar. I only kept the axle and the tow hitch. I threw everything else away. Looks like your A frame is pretty

sturdy so if you keep that, you will really only need to make a couple of cross braces and a rear piece for the lights and number plate. I got the U

shaped pieces folded at the same time. all in 3mm and used them for the cross bracing and the A frame.

The rear part is mounted so that the lights are inside the U shape. this gives the lights all the protection and saves damage. the reflective

triangles are mounted on the rear of the mudguards.

cosmick

owelly - 29/9/10 at 10:26 PM

Here's my effort.

Made from 2mm.

And then galv dipped.

I used those clampy type supports at the rear for use during loading/unloading.