Chris_G

|

| posted on 4/4/06 at 03:28 PM |

|

|

Making up Battery Cables

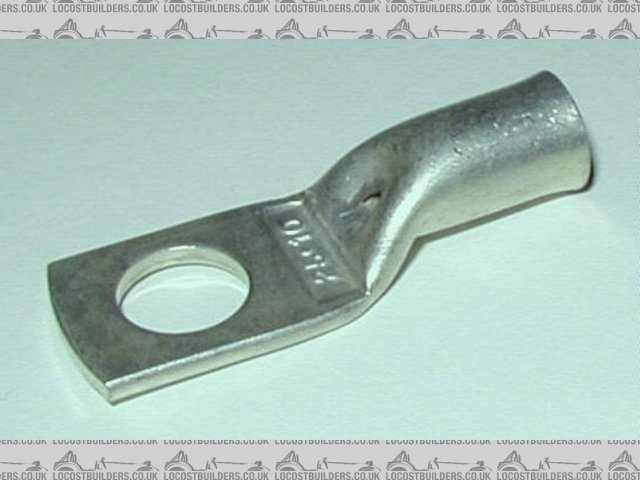

Has anyone got any tips regarding soldering on copper tube terminals (as shown below) to battery leads. My concern is that the insulation is going to

fry in the process. I was planning on giving the lead and the terminal a coat of flux then wrap some cold wet rag around the insulation while I hit

the terminal with a blowlamp and solder. Does this sound ok or am I headed for disaster? I have bought heatshrink to cover everything up nicely when

done.

Cheer

Chris

Rescued attachment ctt25.jpg

Now finished! Xflow-Zetec swap with GSXR TB's and Megasquirt.

|

|

|

|

|

givemethebighammer

|

| posted on 4/4/06 at 03:33 PM |

|

|

I did mine with a small gas torch (type chefs use to brown top of puddings). The insulation melted a little but the heat shrink covered it up. I think

a full sized blow torch might make a bit of a mess - I might be wrong).

Rescued attachment cooks_blow_torch.jpg

|

|

|

skydivepaul

|

| posted on 4/4/06 at 03:35 PM |

|

|

you can always cut a slot in the terminal and crimp the cable on. Most aftermarket leads are crimped and not soldered. Makes a neat job if your

soldering isnt up to scratch and the big terminals are difficult to get right and look good.

http://www.smartideasuk.com

http://www.smartmapping.co.uk

HD CCTV

3D design solutions and integration

IP security systems

access control systems

|

|

|

David Jenkins

|

| posted on 4/4/06 at 03:36 PM |

|

|

I did the same - the sleeving went back a few mm, but I covered that with glued heat-shrink.

The only alternative is to crimp it - but who's got one of them when you need one?

David

|

|

|

dave r

|

| posted on 4/4/06 at 03:39 PM |

|

|

i have

|

|

|

rayward

|

| posted on 4/4/06 at 03:40 PM |

|

|

I'v got the crimpers to do them, if your really stuck and want to post them to me, i could do them and post em back.

Ray

|

|

|

Chris_G

|

| posted on 4/4/06 at 03:48 PM |

|

|

Thanks for the replies guys.

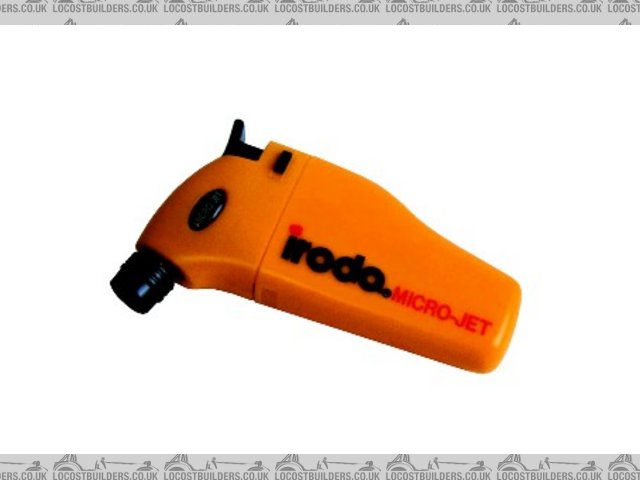

I've got a mini blow lamp as shown below and my soldering is usually pretty good so I think I'll give it a go with one end and see how it

comes out. If it looks a mess then I'll give you a shout Ray!

Cheers

Chris

Rescued attachment 27919i0.jpg

Now finished! Xflow-Zetec swap with GSXR TB's and Megasquirt.

|

|

|

ReMan

|

| posted on 4/4/06 at 03:52 PM |

|

|

I crimped mine by layin a steel pin on the front and squashing it in the vice a bit like the crap pic...

Rescued attachment ctt25c.jpg

www.plusnine.co.uk

|

|

|

Peteff

|

| posted on 4/4/06 at 04:18 PM |

|

|

If you bare the end of the wire then stand the terminal up in the vice, heat it up with the blowlamp and fill it with molten solder, flux the cable

them just plunge it in and let it set it will hold.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

Hellfire

|

| posted on 4/4/06 at 04:21 PM |

|

|

quote:

Originally posted by Peteff

If you bare the end of the wire then stand the terminal up in the vice, heat it up with the blowlamp and fill it with molten solder, flux the cable

them just plunge it in and let it set it will hold.

Yep - it does

|

|

|

Kissy

|

| posted on 4/4/06 at 04:49 PM |

|

|

Plumbers soldering iron will do it (circa 85w IIRC) Blow lamp is a bit on the hot side. You don't want the solder to capillary up the wire too

far otherwise it'll be prone to cracking later in life. Best is to crimp and then use adhesive lined heat-shrink to seal the job (if you use

clear you can stick +ve or -ve label inside). The heatshrink also acts as a good strain-reliever.

|

|

|

Anglia66

|

| posted on 4/4/06 at 09:19 PM |

|

|

I took my battery cables to a local auto electricians and they crimped the terminals on for a drink.I had previously cut them all to the correct

lengths.

|

|

|

02GF74

|

| posted on 5/4/06 at 07:17 AM |

|

|

quote:

Originally posted by ReMan

I crimped mine by layin a steel pin on the front and squashing it in the vice a bit like the crap pic...

Don't solder it. You want a solid cable to terminal contact.

ReMan is right; that is how I did it. A short lenth of rod e.g. a cut down bolt then put in vice and give it a good squeeze. I put the rod on the

underside.

The connection will be physically stronger and better elecrtically.

|

|

|