VDO Oil Pressure Gauge Sender Full or Zero Scale Fault Finding

Just a quick note for a little fault finding on oil pressure sender. I have VDO equipment but all operate with same principles.

When I first got the Westfield, the pressure gauge would read around 5-7 Bar, which is unusually high, then within a few weeks, as soon as ignition

was switched on the gauge would go full scale, i.e. right past the 10 Bar mark without even starting the engine, so obviously not true reading.

I initially thought wiring fault / earth fault. After point to point testing with the wiring proved wiring OK, I had to assume it was either the gauge

or the sender.

Bearing in mind I knew nothing about oil pressure systems on vehicles, I had to do a little research on the manufactures websites and also other

forums to get a bit of knowledge.

So…

Description

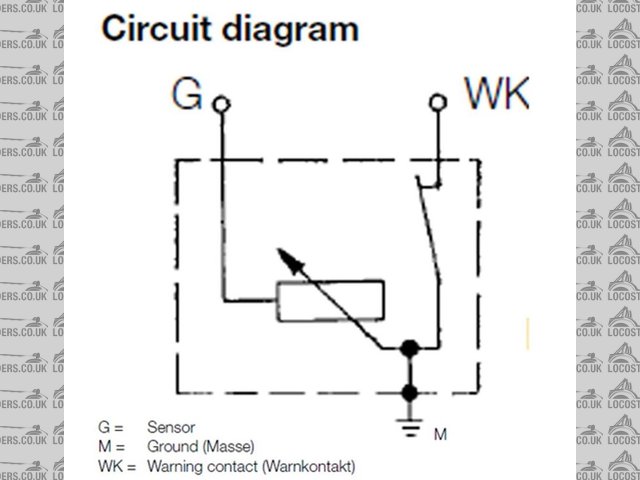

The circuit diagram shows that the sensor requires a good earth to operate correctly.

The Gauge goes to ‘zero’ when ignition is off because the sender gets a short to earth, so zero resistance, good continuity, ‘0’ Bar reading in the

scale.

The higher the resistance, so poor continuity to earth, the higher the reading on your gauge.

A simple check to do is remove the wire, in my case, from the ‘G’ terminal on the sender and the gauge should read full scale, (which it already does

anyway.)

Touch this wire the engine, (i.e. a proven good earth point), the gauge should read back down to ‘0’. This proves wiring and gauge OK.

Touch the wire to the external metal casing of the sender unit. You should get a ‘0’ reading on the gauge once again.

If you don’t, it’s one of two faults.

a. Poor earth continuity.

b. Sender is faulty.

If it is a. check the installation of the sender, there should be NO thread paste or PTFE tape between engine and sender, (and any adaptor that

you may have installed.) The threads are tapered so this will nip up and no sealant will be required. You can also use a multi-meter to test

continuity from engine to adaptor to sender to prove ok or locate the high resistance.

If this checks out ok, then it will be b. (No thread tape on mine and I checked continuity with a multi-meter and had an excellent continuity. 0.0

Ohm.)

I have a dry sump system on my car which the majority of oil returns to so I didn’t have to drain any oil out to remove the sender. I just jacked the

front end up so any remaining oil would pool at the back of the engine.

I removed the sender from the engine and it rattled like a baby rattle. Issue found.

I also noticed straight away that it was a 0-5 Bar sender and my gauge is 0-10 Bar.

Description

Description

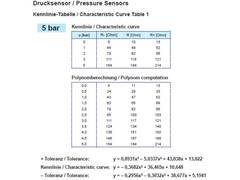

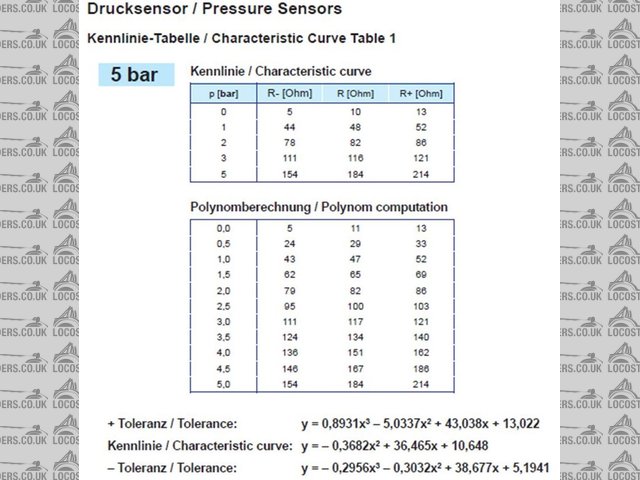

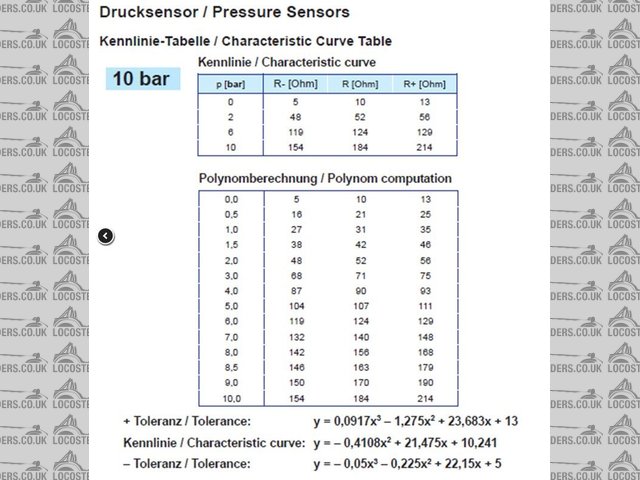

Looking at the OEM data sheet the resistance values are approximately the same whatever range sender you have.

For example, 0-5 Bar = 0 – 184 Ohm resistance. 0 Ohm = 0 Bar. 184 Ohm = 5 Bar.

For example, 0-10 Bar = 0 – 184 Ohm resistance. 0 Ohm = 0 Bar. 184 Ohm = 10 Bar.

So with mine being mismatched, that meant, if I had actual oil pressure of 2.5 Bar with a 0-5 sender and 0-10 Bar gauge, it would show 5 Bar.

This means I had solved the initial higher pressure reading at the beginning and needed to buy a correct range sender anyway regardless of the actual

full range fault.

New 0-10 Bar sender bought and fitted, perfect.

The WK terminal is for an oil pressure light by the way, switch will be closed illuminating a light until engine started and once the pressure rises

past the minimum, (which varies between senders so make sure this is correct for your application), the switch will open and light will go out.

Hope that all makes sense and easy enough to follow.

|