Solenoids / Actuators - Electronic Shift

Howlor - 11/10/05 at 10:52 AM

Hi,

Looking at building an Electronic Shifter but wondered if anyone else had done this and what solenoid they had used. I have spoken to The Solenoid

Company who can make me one for the job.

Thanks

smart51 - 11/10/05 at 11:05 AM

Is this in addition to the mechanical shift or instead of it? I might be interested in a paddle shift upgrade in the future.

mak - 11/10/05 at 11:14 AM

I've heard of a pair of starter moror solonoids being used, no idea how it worked!

Howlor - 11/10/05 at 11:30 AM

I was planning to run it in addition to the standard lever shift. I have also heard about people using starter solenoids although I would regard the

installs that I have seen as been somewhat agricultural! I want to build something more like the Kliktronic device so it looks the part as well as

doing the job.

evo3500 - 11/10/05 at 11:31 AM

check out www.kliktronic.co.uk they do a solenoid electronic shifter i have one fitted to my car it works very well,the tech spec may be on the

website hope this helps.

Regards Simon

jambojeef - 11/10/05 at 12:37 PM

I was thinking about this a while back and read a website somewhere that reccomended using a SAAB starter solenoid since it has a particularly long

throw. This was coupled with a programmable chip and then momentary push to make switched on the steering wheel.

The guy who wrote the website reckoned his wasnt very reliable and it was especially hard to fnd neutral owing to it being a "half click" on

the gear lever.

Been searching for the link but cant find it sorry!

Let us know how you get on,

Geoff

tks - 11/10/05 at 01:06 PM

i wanted the same thing...

but i used an servo from an RC car.

from the querter Scale these have allot of torque...

And i have had it working....

i used the newest servo i could find (digital ones) for more torque.

the last time i checked my system on the car it didn't work and the problem was that the servo broke down.. i think i have burned it some

where..because now it looks it hasn't got enough force any more.

and with my hands the lever is still easy to move...

i made the system in conjuction with my Electric to hydro Clutch also done with an servo!

that one works out standing.

together i had the setup including my accelerator electronic (works great)

because i wanted to make an electronic shift system..

sow it was acelerate full throttle...push an button keep your foot down..

the rest does the computer and it worked very well exept that the servo now is burned i guess and it doesn't has force enough.

the problem with the lever is that it moves from his rest position in every gear..

but i could programm differente coordinates in my system to become that..

if we have an go at an good and cheap solenoid then i'm sure the hole can complete work.. because the solenoid can me actuated with PWM...(an

servo 2, but it forces his position continously)

And in that way the rest position isn't an problem any more..

sow call an price and maybe you can order 2 of them by that company!

i'm interested..

Tks

mangogrooveworkshop - 11/10/05 at 01:35 PM

The user CEEMOB did a system for some builders a while ago Blake had it all sorted but for the accuation problem

Rorty - 12/10/05 at 04:23 AM

You could spend months sorting out the solenoids and then you'd still have to surmount the electronics for it to work. If they're not 100%

they're a right royal PITA!

The solenoids would also have to be powerful enough to move the mechanical shifter too, unless you disconnected it.

A mechanical paddle shifter is a far easier and more reliable option, plus it allows you to "feel" the box when changing.

tks - 12/10/05 at 09:17 PM

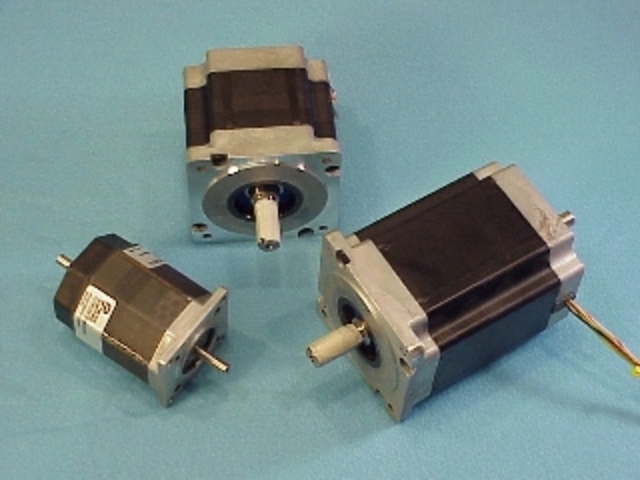

Why we don't use an

Electricmotor and we make an part so that it fits straight on the splines of the box? Whe only will need then an stepper motor or just an electric one

wich we then activate by PWM during xx seconds..

at least its bloody fast then...

Rorty that kind of computers are fun to make,

if any one knows an page where i can upload an movi, i have made on of my clutch and accelarator..

i could make / insert an cruise control for example.... or when i build my electric reverse insert it to the system an just go backwards with the same

acc pedal

untherstand?

regards,

Tks

[Edited on 12/10/05 by tks]

Rorty - 12/10/05 at 09:35 PM

IIRC, Honda use a stepper motor to change gear in some of their non CVT quads. There is also at least one manufacturer of aftermarket stepper motor

gear changers for quads.

ceebmoj - 13/10/05 at 07:57 AM

Hi,

Have build a number in my time and now build a slightly more complex system professionally. From what I have herd talking to people they work fine.

However if I was to do it again I would do some thing differently (I guess that is the same with every thing though).

Using a model servo is a good idea however I would recommend using an industrial one so that is has a good level of sealing preventing stuff getting

in to the gear chain and bearings.

Solenoids work fine. I used the SARB starter motor solenoids that also have a limet switch built in to them. Most starter motor solenoids would

work.

As to wither it is worth it for the driver it is all down to personal taste. I can quote the gear change times and they are faster but some think that

it removes driver input.

I stopped building the system as at the price I charged I made a practically nothing on them and that took up a lot of time. If people are interested

I would make more but would want to build a minimum of 5 preferably 10 to make it a wroth while venture for me.

in my time.

Howlor - 13/10/05 at 08:07 AM

I will see what stepper motors I can find as I have a friend who works in this industry.

G.Man - 13/10/05 at 08:27 AM

All the secuity doors at our bank branches use a 12 solenoid to lock them...

Big sliding pin activated by a keypad, they are 12v and may have enough grunt to run a gearshift...

Rorty - 13/10/05 at 08:34 AM

See if you can borrow them and give us a report how it works out.

Howlor - 13/10/05 at 08:47 AM

Even better just let us have the code and we'll have a look ourselves!

Howlor - 13/10/05 at 08:50 AM

ceebmoj, I would be interested, what kind of price would you be looking for? I may buy 5 from you as I know of a few guys that would be interested as

well.

tks - 13/10/05 at 12:14 PM

i surely would prefer

Stepper motor! wy? they are enormous torquii... and it would create an tremendous fast gearbox...

because how much turns does the lever?

i think its 15/360 that means 15degrees..

not much, and an stepper motor can do the job because it is torqui to di it without lever! also it enables us to disable the motor or program

coordinates in them.

We can use any voltage because we will use pwm to de the job. i have seen running 5volts Steppers on 50volt!

sow if we can find an 5volt stepper and just use the 12volts from the battery with pwm then we are there.

maybe its not the right comparation but in F1 they also hookup an motor directly to the shaft. in our case, if want it faster than fast we will need

to take of the spring..or at least make it weaker....??

Will need to look how i can make an easy stepper motor driver with an small pic and some fets... then we can make the system realy fast.

The only thing what we need to know is some info from an gearbox expert..:

1) what happens if the lever is fully pressed and is held there when you are driveing? does some parts then wear?

2) how much tolerance is there in the rest position of the gearbox shaft?

maybe its just easyer to try it with an wiper motor or an water spray motor ..etc..

because in fact we only need 0,5 sec power in it in either direccion and neutral will be 0,3sec or something..

regards,

Tks

[Edited on 13/10/05 by tks]

tks - 13/10/05 at 12:45 PM

Well neutral

will be seen by the computer,

sow if you are in gear 1 and whants one higer it just keeps moving up until neutral singal comes and then falls away...

if you are in 1 and whant one down (to Neutral) it gives upward until it notices neutral....

sow we can either make the box layout like this!

6

5

4

3

2

1

N

instead of

6

5

4

3

2

N

1

Tks

this solution would be very compact and also fast...any one noticed disadvantages?

the only one i can think of is you cant connect an lever any more. but my goal is that the system is 99% reliable sow don't need a manual

override

have you got pics ceebmoj from that solenoids..

[Edited on 13/10/05 by tks]

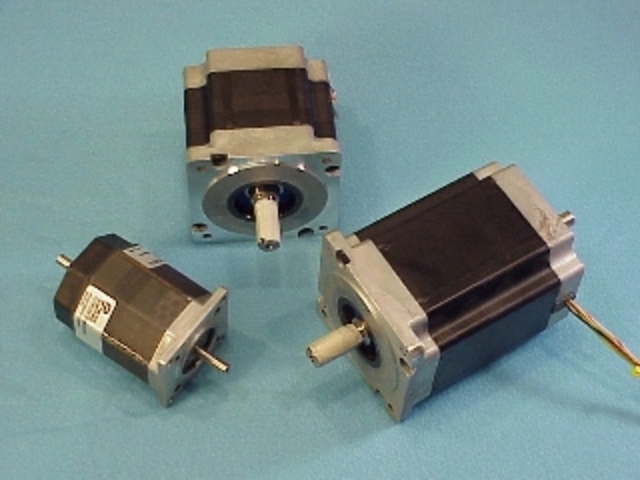

Rescued attachment GearboxMotorShiftsetup.JPG

tks - 13/10/05 at 12:56 PM

See and judge your self..

If you take an good look you see:

- Clutch servo, for precise take off

- Throtle servo, for full throttle shifting

- Acc pedal pot (precise type)

- Box with all the components

mainly the complete fly by wire system is on 1 computer. sow clutch is digital, accelator, shift.

If i press the clutch an relais does for me the task of connecting the 2 wires from the original bike loom. (sow i can start in gear only if i press

clutch)

The neutral switch is also connected to it, sow in Neutral it resets the gear count to 0.

One day i maybe change te clutch servo for an stepper motor as well, it will be more fast.

The servo takes appr. 1sec. to declutch (full movement). 0,6 for clutch(full movement) .... i guess never messured it any way.

anyway i have spare room because when i take off ( ) the servo is at the half of is way...(sow there is room for upgrades)

) the servo is at the half of is way...(sow there is room for upgrades)

Tks

[Edited on 13/10/05 by tks]

Rescued attachment Foto 008 small.JPG

ceebmoj - 13/10/05 at 03:44 PM

hi,

in the pased I have sold the devices - solinoids for around £50 however that was with citcutry to drive a solinoid not a steper motor. I can speck a

stepper motor or if you have a good supply I can design the drive circutry to work with that stepper motor.

and recalcut the cost based on thoues components. and new code.

tks - 13/10/05 at 07:48 PM

Think i will give an normal motor an go first.

Before i go stepper.

before i go at all i will take an look at how complicate / easy an stepper driver is.

because thats at least for me the thougest part.

the reason that an stepper motor has allot of torque is because it puts allot of energie to displace something for an small distance! think about it

the standard step is 1,4degrees. and then we can go half step and micro step!

the disadvantage is price and weight.

i think if i make it with an normal motor it will be an bit like slamming on the axle sinds you cant position it..or at least give it an easy turn

limit...

on the stepper one, you send 5 pulses and it wil make 5 steps..(if it has the torque...) sow without encoder you send 6 and you are done..

if use encoder (an device that tells you how much steps it did make in reality)

then we have an closed and 100% closed system but also the most expensive..

also an encoder can be mounted on the motor at any time (thats the reason the shaft sticks out at 2 sides of the motor)

gonna google!

Tks

davidwag - 13/10/05 at 09:05 PM

Hi,

The LUK designed paddle gear change, on things like mercedes A class, use a motor identical to a rear wiper motor. Complete with worm gear and

operating arm, with feedback from a potentiometer. So operating like a servo.

David

tks - 13/10/05 at 09:29 PM

With an stepper motor we can make the setup more compact.

Because of the little movement we need, i'm also thinking of using an Pot meter as an Position device (for feedback).

(It will be connected to the shaft of the stepper motor)

the only problem is how much torque is needed to turn an gearbox lever.

my servo in its best time could select first gear even with the engine not running.

altough i will disable this option in further software updates(i guess)

Have read 5volts 1amp gives 320N/mm of torque.

Thats 32Kg/mm thats 3,2Kg/cm

sow an shaft with an thickness of 1cm will

towup 3,2Kgs - the weight of the cable used(rope)

My Digital servo has 186N/cm,

that means it has 18,6Kg/cm.... but..

i used an action radi on it of lets say 25mm ==> 7,44Kg left...

The gearbox shaft was lengted with let say 85mm.

Sow pulling with 7,44Kg on an shaft of 85mm will do the trick! lets reduce the 85mm to the 15 of the shaft. its an factor of 5,6.

Sow on the shaft we need an force of 5.6*7.44Kg of torque is this right?

41Kgs

Tks

[Edited on 13/10/05 by tks]

Howlor - 14/10/05 at 09:31 AM

http://cgi.ebay.co.uk/4-pcs-Size-23-Hybrid-Stepper-Motor-Astrosyn-EE163-5_W0QQitemZ7553818813QQcategoryZ26209QQrdZ1QQcmdZViewItem

Do we think these are too weak?

Thanks

tks - 14/10/05 at 01:26 PM

its sow hard to say!

don't we have some one over here who owns an..

torq wrench?

what if we make an bit to fit the shaft

and with our torque wrench we search for the value that you cant switch??

another one would be simply with an spring unster (an device with an linear spring) sow you can measure how much Newton is neccecary to operate an

gearbox.

i have to omit that my calcs maybe out of question due to the fact that i'm certanly not pulling with 90degrees at the lever..

sow then there is much more force needed to operate the thing.

what the minimum value of an torque wrench?

Tks

tks - 14/10/05 at 01:31 PM

ok, i think that we can buy them.

Then we will instead of hook it up directly make use of an transmission...

(we search for 2 teethed wheels and an belt, in that way we can also hide the motor perhaps better from debris etc.)

Do you but them or will i?

Tks

p.s. if they aren't of any use, i will find another project where i can use them...

Bob C - 14/10/05 at 03:51 PM

It's easy & cheap to make a positional feedback servo using a quad op-amp for control & an audio stereo amp chip to do the power - if

anyone's interested I'll dig the old circuit out (did it for controlling a waveguide attenuator on a sat. comms project - worked a treat)

Cheers

Bob

tks - 14/10/05 at 07:49 PM

We will first need to know that including transmission the force will be enough..

Than we know wich electronics we need (watts) then we can make an choice how to do it.....

think we need the middle one..

Rescued attachment Stepper.jpg

tks - 17/10/05 at 12:26 PM

is there any new news?

Solenoids?

Stepper motors?

Think i will do the test and buy one..

Cheers.

Tks

MikeRJ - 18/10/05 at 04:33 PM

I can't think of a less suitable actuator than a stepper motor for this application. Affordable steppers are for low/medium torque applications

that requires very precise positioning. They are difficult to drive above a certain speed, have low holding torque and no positional feedback as

standard (so if it skips a few steps we won't know).

For gear changes we need fast, meduim-high torque movement. Precision of movement is of secondary importance. A powerfull servo motor would be good,

but expensive. A cheap, servicable DIY solution is simply a geared motor (e.g. a windscreen wiper motor is very suitable) and limit switches.

A friend of mine built a twin engined Metro turbo, and gearchange on the rear engine was achived only through the above method, controlled by

microswitches on the gearlever mechanism. It did require a lot of setting up, but when it worked it changed gears very quickly and smoothly.

ceebmoj - 18/10/05 at 09:56 PM

hi,

it is also worth remembering that DC single winding motors will have a difrent torque avaloble at start up depending on the position of the coil

having said that a windscrean wiper motor as sigested would be good and rather than limit switches you could very easely add a rotary encoder to the

motors shaft witch would give you a good degree of controle.

it might be easer for a hobby builder however to build a system that uses a ac motor and and a H brige to get the same control you could sence the

speed and recolotions from the coils that way as well rather rhan using a rotary encoder.

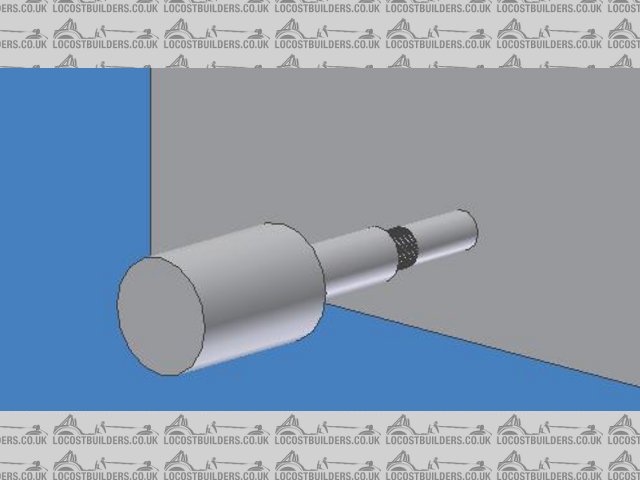

davidwag - 20/10/05 at 07:20 PM

Hi,

Found a picture of LUK ASG gearchange actuator.

Look familiar??

Rescued attachment asg.jpg

tks - 20/10/05 at 07:24 PM

for what kind of gearbox is that one??

looks for me like an truck example?

pff...

think we need to build an servo with a wiper motor/window motor scooter starter motor.

And add an rpm counter on it..

TKs

Rorty - 20/10/05 at 09:28 PM

What do mhhh, mhh, pwww mean? Are these some electronic acronyms I should be aware of?

ceebmoj - 25/10/05 at 07:57 AM

Hi a quick Google and look in other web forums admittedly games ones where there are a lot of 1337 (see http://en.wikipedia.org/wiki/Leet) 0wning

hacks seams to show that they are in reasonable use with here history being traceable to the Simsons or another animated series. So look out Oxford

dictionary hear we come.

There have be discussions in hear before about spelling, grammar and English in general. Witch have left me reasonably offended in the past. So how

about if you can read a post and understand the general idea or concept the author is trying to express post your reply to that question / idea and

steer away from what could be seen as offensive to others.

[Edited on 25/10/05 by ceebmoj]

tks - 25/10/05 at 12:07 PM

what does rorty mean? funny guy??

Tks

tks - 27/10/05 at 07:43 PM

Well this is the old working situ.

What has happend is that the voltage regs wich gave the power to the servo where dead!

And the other one is almost dead.

i putted 2 in parrallell for more amps.

Think i will make an powersupply

In that way i can deliver to every board.

an nice non spikey 5volt or 12volt.

Or 6volts in case of the servo's.

Regards,

Tks

[Edited on 27/10/05 by tks]

Rescued attachment ServoSitu.JPG

stu da rude - 29/10/05 at 12:01 AM

This thought had crossed my mind before too, a guy built one with two starter solenoids which didnt work; couldnt get them to engage/disengage with

any precision.

its here:

http://biketransplant.tripod.com

under electronic gizmos tab.

Bob C - 29/10/05 at 06:17 PM

The problem, I think, is that a solenoid can be programmed by an ecu & power amp. to give a specified 'impulse' to the gear lever, but

this is never going to overcome the fact that the impulse required varies with temperature, wear, speed, which gear it is (1st or 6th) and whether the

dogs are nicely lined up or not! I'd be interested to see how folk get on with servos - that could be the answer!

When you change gear with your foot you 'feel' it engaging, you don't just give the lever a kick!

cheers

Bob

tks - 1/11/05 at 08:15 PM

should foot be hand?

or what do you feel??

Clutch?

Tks

Bob C - 2/11/05 at 12:05 AM

On the bike it's your left foot - in a BEC it would be hand yes! I'm just saying, change gear manually & you have feedback (tactile), a

solenoid, even micro controlled, is just giving the lever an impulse - the gear may slip in or it may baulk, it must be very difficult to make it

reliable. At least a servo will do its damnedest to reach the detent position & this may be a crucial advantage. Or it may not!!!!

I'm vaugely hoping someone will do all the donkey work for us all & find out the hard way!

cheers

Bob

tks - 2/11/05 at 01:00 PM

the only thing i noticed is that when selecting first gear...

it makes an hard noise like Bangg!!

but i think its just the propshaft movement wich turns an quarter and then gives an bang in the box.

When it works i will make an video...with the noise..

This saying, my engine is now very quiet and when i tested the system it was louder... sow dunno how the system is now....

i'm sure that when the prop is fixed..(i mean the teeth in the diff are touching each other) the bang should be gone...

We will see, the failure of the system is due a power suply problem.

when i have time i will fix it.

Tks

maybe its the clutch touching when the oil is cold??

any way it sound like when you hit an bell

[Edited on 2/11/05 by tks]

madman280 - 24/11/05 at 02:54 AM

http://www.mcmaster.com/ page 909 Sealed Linear Solenoids

tks - 24/11/05 at 01:14 PM

They do like indeed very much on the Kliktronic system....

But we have to say that it only likes 1inch travel.

And i think we need 1 inch up and 1 inch down.

it will depend also on the lenght of the gear lever offcourse...

also we need an certain amount of power!

Servo:

Don't know if i mentioed earlyer but my servo wasn't burnt! what whas gone where the 2 voltage regulators...

I have now hooked up 3 of them...

(3x1,5amp) with big cooling surface..

Now my system is again full operational....

Tks

will make a movi of it when i can sow we can judge the bling when it enters first gear....

tks - 24/11/05 at 01:35 PM

Bob,

the tactile is very difficult to get,

The hardest point is getting the arm lengts just right saying you use every movement of the servo going from First gear to second... its the hardest

part of the making of the system.

Also my micro knows in wich gear it is.

For the safety and automatic calibration,

i builded an reset in, i connected the Neutral switch to the board.

Sow the micro knows when its in Neutral.

and resets his counter to 0.

Then when it fails to engage first gear.. he knows he is in 0 again. (it resets the counter it self).

When you move from first to second and it fails you are in Neutral then again he knows he failed....

Once in 2 nothing can go wrong.

2 and up never have failed during testing etc.! (i haven't driven in all the gears) but tested only up to 2nd.

the rest of the gears i tested with the wheels from the ground/ only with diff connected (no wheels)

the most difficult is to select first, because it needs the most force of all..and then you have the problem to go to 2nd because it requires the most

of travel of all... (you feel the chit? most power/most travel...)

i have had situations that i needed more force for First but could engage 2nd.

you can see on the pic that i'm pulling on an angle..its deff against me.

Sow for the rest of the community wich have an better situation they shouldn't care..

The board also has an Relais sow when you push clutch sow you can start while in gear etc.

(i didn't wanted to mess with the loom)

Regards,

Tks

I am uploading an Quicktime movi to an free server sow you all can see how i made the system. Please turn the sound of (its me who speaks) its in

dutch (i don't like to hear it).

Will post the link as soon as the 57MB file is there...

LINK TO FILE

[Edited on 28/11/05 by tks]