pre_layout

Measuring the sensor layout and route I transferred this to paper, the ecu bottom middle, and the sensor plugs at each position. Each place has the cable colour, the plug pin number and then the ecu pin number. Loads of prep work made being confident with each cut easier.

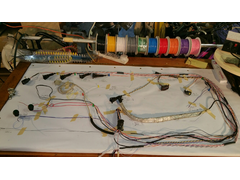

The cables were laid out, and cut, each joint soldered and covered with heat shrink.

layout

The loom was finished as below, and then tested in the car for fit before wrapping in plastic trunking,. not the neatest, but, and a massive but, it now works

Now to re-wire the whole car.

might take a little longer, especially when finding odd things like a 10v regulator that's not on any of the wiring diagrams,. and the fact that all the wiring is pink or yellow!!

Nights in the garage coming up