matt_gsxr

|

| posted on 19/6/10 at 02:49 PM |

|

|

MAT temperature over compensating in MegaSquirt

Right then.

I have an MS1 on my GSXR1100 with GSXR1000 throttle bodies.

I have a cold air feed, and a large airbox and the air temperature is fairly stable (i.e. maybe up to 10deg above ambient).

When I log in the evenings I get different VE maps than when I map in the day time (VE table is richened up when I run during the day). When my

engine got really hot (before cold air feed at a track day) the inlet got properly hot (52deg C) and the fueling leaned out.

Therefore I am deducing that the MAT (Manifold temperature correction, gammaE) is compensating too much. I think this is probably due to it

correcting for density (which is lower), but not correcting for viscosity (which is also lower).

So, it seems that I need to "turn down" the MAT correction. Can I do this? The "coolant related air-density" page has some

settings (in tunerstudio) that have some credible settings, but I can't find a manual that says what I should be doing.

Any thoughts appreciated. I could modify the sensor (or associated code) so that it lies about its temperature but I'd like to try to do this

properly if I can.

Matt

|

|

|

|

|

GeoffT

|

| posted on 19/6/10 at 03:28 PM |

|

|

Not sure if you've already seen this page in the manual but it does give an albeit brief description of the coolant related air density

function:-

http://www.msextra.com/doc/ms1extra/MS_Extra_Software_Manual.htm#cooldens

[Edited on 19/6/10 by GeoffT]

|

|

|

turbodisplay

|

| posted on 19/6/10 at 09:24 PM |

|

|

The problem is heat soak, being a NA engine could you put the sensor futher away?

Darren

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

flak monkey

|

| posted on 20/6/10 at 06:40 AM |

|

|

Either turn it off and see how it goes, or reduce it to 50% which I have usually found works. The theory behind it is right, but the unavoidable heat

soak messes it all up.

Sera

http://www.motosera.com

|

|

|

matt_gsxr

|

| posted on 20/6/10 at 07:17 AM |

|

|

So, heat soak.

Does that mean that. As the new air rushes in it is nice and cool, but the ECU doesn't realise because the sensor doesn't react quick

enough. Or is it to do with heat being picked up by the air after it has left the airbox?

So, long-term I will need to. Insulate the airbox (which was always in the plan), and change the sensor to one that doesn't have as much

thermal capacity and is as near to the inlet as possible (without being silly!).

Short term. Change the MAT factors. Sorry to be slow, but how would I turn down the MAT to 50%. I have read the manual, and it is all a bit vague

in this area (I am on MS1, running 29y4 extra code, and using tunerstudio, but can use the older megatune code it that helps).

Matt

|

|

|

turbodisplay

|

| posted on 20/6/10 at 08:36 AM |

|

|

As the air increases by 10c the density of the air reduces by 3%. If the megasquirt copensates by only 1.5% then the heat soack is less of an

issue.

I find the ats04 sensors with an open element less prone to heat soak.

It is the heat of the outside part of the sensor traveling up to the tip.

Darren

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

matt_gsxr

|

| posted on 20/6/10 at 04:49 PM |

|

|

Darren,

Thanks for that sensor advice.

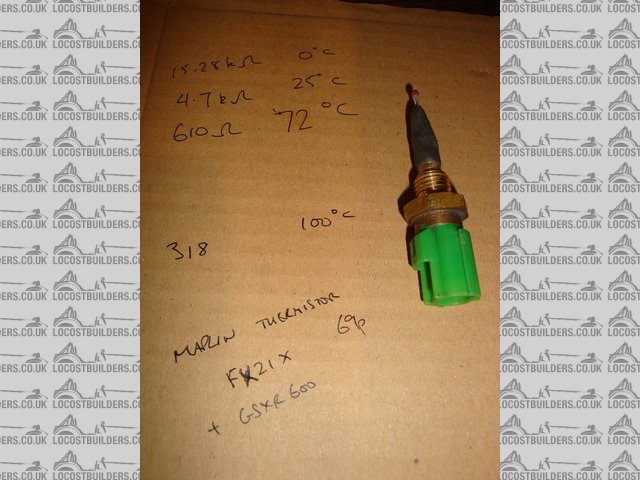

I have the standard suzuki gsxr600/750/1000 green sensor, which is basically a big solid conductive lump of brass. This is hard mounted to my alloy

airbox, so it isn't a big surprise that it is affected by the under bonnet temperature.

I have cut the brass off the end of the sensor and soldered on a thermistor from Maplin. This sensor has a time constant of 12seconds, and is no

longer coupled to the brass fitting. To manage vibration I have used some of that "epoxy metal filler" stuff. Its response in my "cup

of tea" test is much much faster than the big brass one. Not bad for 69p. Now I just need to do the easytherm thing (I am on MS1, so can't

do it with MegaTuneStudio).

maplin_thermistor_plus_gsxr600

I still need to lag the air-box, but now I have proper air temps things should work better.

Hopefully go for a potter tonight to see if it helps. Interestingly the higher AFR hasn't hurt the power, previously I had been aiming for 12.7

at WOT and high RPM, so once this is controlled better I may aim a bit higher (maybe 13.2 for a start). Too risky until I have good control of this

though.

Matt

|

|

|