Manifold Air Pressure on Megasquirt

chasmon - 15/10/07 at 06:07 PM

Thought I'd post under a new subject title as the other thread title isn't really relevant any more.

Engine starts and will idle if I crack open the throttle a bit.

Looking at real time data the MAP signal is sat at 90kPa. Should this not reduce significantly with throttle almost closed. I have removed the vac

take off and I can get it to go down by sucking on it...

Its plumbed into the manifold through the channel in the gasket to get a reading from all TBs. When the engines running I can't feel any suction

on this though.

Does this imply a leak? I've sealed everywhere obvious including the original vac take off points.

Any opinions apreciated

Charlie

chriscook - 15/10/07 at 06:43 PM

How much throttle opening when you get 90kPa? It sounds like you have ITBs which change MAP very quickly with small throttle openings.

I get about 50kPa with GSXR throttle bodies on my XE (or did until the rod came out the side in bits...

chasmon - 15/10/07 at 06:56 PM

It's 90kPa and doesn't change open or closed...

They're GSXR750 TBs

Was wondering how much I should be able to feel the vacuum on the line if I disconnect it and put my finger over it...?

Thanks for the reply, sorry about the XE!

piddy - 15/10/07 at 07:01 PM

What throttle bodies are you using?

90kpa is the highest my mega squirts reads at full throttle. I'm using GSXR's

40kpa being the lowest. My MS is connected to the four pipes that go direct to the throttle bods.

I would have thought with the throttle slightly open you should be seeing a reading of 50-60 Kpa.

MkIndy7 - 15/10/07 at 07:22 PM

I would have thought the 750's will be less restrictive than the 600's and as a result you will get less vaccume.

We had even less than that with out R1 ITB's plumbed into every TB, it was in the 90's most of the time and went as low as 35 on severe

engine breaking.

Gave up in the end and started using TPS to tune it with, as it was explained that by using ITB's we'd tried to make everything as free

flowing and easy for the air to get in that there is resistance and therefore no vaccume! even with the slightest throttle opening it was sucking in

easily available air with no restriction.

paulf - 15/10/07 at 07:39 PM

My zetec idles at 43kpa and at cruise it is 80 - 90 kpa.You should see a good vacuum at idle no matter what TBs are fitted , i would suggest blanking

off the ford gasket type take off and connect to the TBs at the original take off points , join all 4 together and then use an inline fuel filter as

an acumalator .

Paul.

chasmon - 15/10/07 at 08:43 PM

Thanks all!

I still have the T pieces for the vac take off that came with the TBs so I'll unblock them and blank off the ford take off and see what I get.

I presume with the engine stopped the MAP sensor should read around 101kPa - atmospheric...?

Good advice as always.

C

paulf - 15/10/07 at 09:35 PM

You may need to put a restrictor in the commoned line between the TBs and ecu to dampen the fluctuation a bit, i used a .6mm mig nozzle.

Paul.

quote:

Originally posted by chasmon

Thanks all!

I still have the T pieces for the vac take off that came with the TBs so I'll unblock them and blank off the ford take off and see what I get.

I presume with the engine stopped the MAP sensor should read around 101kPa - atmospheric...?

Good advice as always.

C

chasmon - 16/10/07 at 04:28 PM

Cool cool I should be able to drill something down to that size if its just an aperture required. If its a longer length at 0.6mm ish I may have to

get something in.

zetec mike - 16/10/07 at 05:46 PM

I used an old idle jet from an old carb which was much smaller, it did damp the pulses nicely and pushed nicely into the vacuum line. However, I could

never tune it properly so ended up going to alpha-n.

chasmon - 16/10/07 at 07:32 PM

Getting there... Connected the old system from the bike up and now I have a lovely MAP signal. It doesn't seem too unstable but I'll add a

aperture in the line anyway to smooth thte signal.

Next problem I have pops coming from cyl 3 when the throttle is closed/almost closed. Looking down the TB I can see flames behind the butterfly.

This is where I show my ignorance but I'm guessing this would indicate the timing is out badly...?

Running the latest firmware of MSnSE and EDIS on LED17.

Spark settings as per MSnSE website for later firmware and EDIS (AFAIK):

piddy - 17/10/07 at 06:37 PM

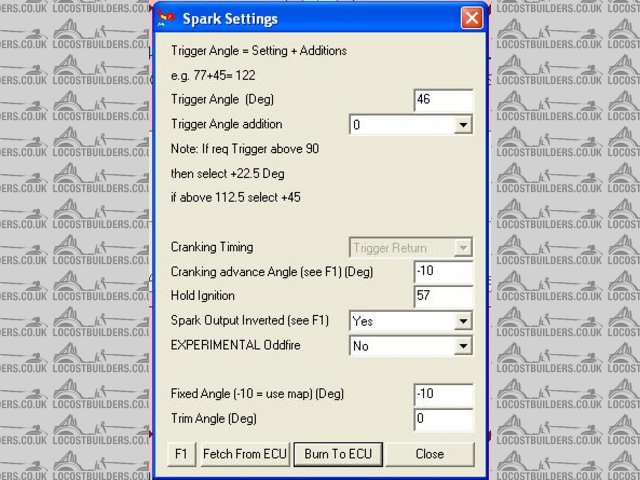

Mine is set as this.

Rescued attachment spark.JPG

chasmon - 17/10/07 at 07:16 PM

Thats interesting. http://megasquirt.sourceforge.net/extra/setup-edis.html on here it has the setup as per mine. Are you using EDIS?

Have been thinking that the flames may be due to this throttle being closed and little air getting into the engine hence very rich and the burn is

slow still burning once the valve opens and then the flames meet fresh oxygen. It doesn't pop or bang like this under throttle...

zetec mike - 17/10/07 at 07:55 PM

Have you balanced the throttle bodies ? If its only affecting one cylinder its unlikely to be timing. I made the mistake of balancing the throttles

by eye before fitting and wasted loads of time trying to tune the idle because I forgot to balance them once the engine was running.

Easiest way is with a length of tubing and listen in each port at the buterflies.

chasmon - 17/10/07 at 08:19 PM

Nope throttle bodies not balanced so I'm guessing that could be the issue. Just unsettled me a bit having flames out the wrong end...  I'm

guessing its the fact that there's not enough oxygen in that one cylinder to burn properly.

I'm

guessing its the fact that there's not enough oxygen in that one cylinder to burn properly.

chriscook - 18/10/07 at 08:09 AM

First thing to do then is balance them. Using a bit of hose is surprisingly effective. I used this method at first on my carbs but then bought a

proper synchrometer and my efforts with the hose were very nearly spot on.

piddy - 18/10/07 at 07:12 PM

Hi.

Yes I'm running EDIS.

Mine is set this way because I borrowed a map from someone else.And thats what it was set on. I've changed lots of the settings but not this one.

(not yet anyway)

Could you send me a link or put it on here where you read how to set the trigger angle setting?

I agree my engine ran a lot better after I balanced the throttle bodies.

chasmon - 18/10/07 at 07:17 PM

quote:

Originally posted by chasmon

Thats interesting. http://megasquirt.sourceforge.net/extra/setup-edis.html on here it has the setup as per mine. Are you using EDIS?

Have been thinking that the flames may be due to this throttle being closed and little air getting into the engine hence very rich and the burn is

slow still burning once the valve opens and then the flames meet fresh oxygen. It doesn't pop or bang like this under throttle...

I posted it up there ^^^^

zetec mike - 19/10/07 at 08:11 AM

The other reason for flames could be due to valve overlap between exhaust to inlet and the fact there is also the wasted spark at this point. My

feeling is the balancing is out giving too little or too much air so incorrect combustion.

piddy - 19/10/07 at 02:48 PM

hi. I must start to read all of the text not just parts of it

After reading the instructions it looks like if you have the Fixed angle set at -10 as we both have it de-activates the trigger angle setting.

chasmon - 21/10/07 at 07:38 PM

Had some thoughts on this and decided the spark timing must be correct as if I disconnect the SAW signal from the Megasquirt the problem is still

there... The EDIS puts the advance to a safe value in the event of CPS failure.

More thoughts - I've checked the CAM alignment and its spot on. So.... Only thing I have left is the fuelling. I'd like to set the

butterflies correctly but with the explosions coming out of the throttle bodies I'm a bit concerned. Plugs are quite blackened too...

Its not restricted to one cylinder any more but mainly 3 and 4... I'm guessing it could be majorly over fuelling but I guess a Wideband may be

the answer...

Any advice appreciated as always!

chasmon - 24/10/07 at 10:44 PM

To finalise this thread. I have richened up the mixture and it has stopped the problem. The problem is apparently caused by lean mixture burning

slower and hence it is still burning when the valve opens allowing it to ignite the air fuel mixture in the TB...

Thanks for your help all.

I'm

guessing its the fact that there's not enough oxygen in that one cylinder to burn properly.

I'm

guessing its the fact that there's not enough oxygen in that one cylinder to burn properly.