Fuel tank breathers - again!

DaveFJ - 18/7/07 at 10:27 AM

OJK - I know this has been discussed a LOT and I know i need a breather...

I just wanted to sound out an Idea i have for fitting one....

I have an Ally tank courtesy of Deneo. Unfortunately when i specified it I hadn't thought things through fully so only asked for supply and

return lines and a filler....

My fuel cap is sealed so breathing there.

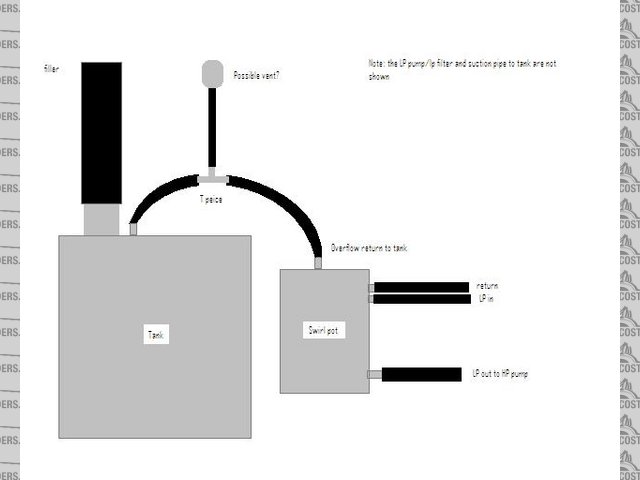

I am fitting fuel injection so have a lp pump sucking fuel through an lp filter into a swirl tank which supplies the engine bay HP filter. the return

from the engine bay goes back to the swirl pot. The swirl pot then has an overflow which returns to the tank.

My idea is this: to put in a T piece at the highest point of the loop of pipe going from overflow back to the tank and fit a breather... beacuse of

the design the breather could NOT be higher than the filler orifice as some have suggested.

SO... opinions? is this workable? or just a crap idea ??

or just a crap idea ?? or do i need to start looking at fitting a breather direct to the tank somehow?

or do i need to start looking at fitting a breather direct to the tank somehow?

here is a piccy if my idea:

breather idea

[Edited on 18/7/07 by DaveFJ]

oadamo - 18/7/07 at 11:01 AM

i dont think you need one one the swirl pot as its hi pressure from the pump.

adam

David Jenkins - 18/7/07 at 11:23 AM

Personally, I would use a vented filler cap - but I bet you've already got your filler, and that it's not vented!

I know... No help whatsoever...

David

oadamo - 18/7/07 at 11:37 AM

dont no if these are any good.

adam

DaveFJ - 18/7/07 at 11:58 AM

quote:

Originally posted by David Jenkins

Personally, I would use a vented filler cap - but I bet you've already got your filler, and that it's not vented!

I know... No help whatsoever...

David

yup... nice little aerocap all fitted....and not vented

matt_gsxr - 18/7/07 at 12:27 PM

Dave,

Your method may work. I guess the return flow from the swirl pot may elevate the pressure near the vent, which may prevent it venting perfectly, and

could result in lower pressures in the tank. Unless these are low enough to implode the tank you will be fine, but that is easily tested, and

doesn't seem very likely!

Putting an additional breather hole in the tank isn't very difficult, and might be the simplest.

If you use something like a TRV45 (I think that is what it is called, from thinkautomotive about £20) then you just drill a hole, pop it in, and

tighten up a nut on the underside.

This does assume you have a big enough hole somewhere to get at the nut (inside the tank), but a hole for a sender does give you sufficient access.

Presumably extra care is required drilling a previously filled tank.

Matt

RazMan - 18/7/07 at 12:48 PM

I don't think a vent in the return pipe is a good idea at all - I think the pressure will be enough to flood the vent as soon as the pump

starts.

As Matt says, the best solution is to fit a vent direct to the tank, failing that how about a small pipe drilled into the rubber filler neck?

DaveFJ - 18/7/07 at 01:08 PM

I don't think I have a hole big enough to get to the back of any fitting on the tank so would need some kind of blind fitting - can anyone think

of something?

The T peice isn't in the main return from the

HP side but in the overflow from the swirlpot. But I am worried in case the combination of the HP return and the LP pump output are consistently

larger than the HP pump draw in which case the overflow will be constantly flowing fuel back to the tank...

So I guess that answers my own question - the T peice was a silly idea!

I had thought of maybe using a large rivnut and then screwing in a length of tube with an outside thread (or a drilled out bolt). this would leave a

narrow hole and I could attach a tube to go to a valve. I thought maybe I could coat the rivnut with sikaflex before fitting to ensure a seal. I

reckon as it is just an air vent it doesn't need a large hole?

what do you all think?

BenB - 18/7/07 at 04:11 PM

How have you attached the fuel tank to the filler cap?

If its hose you could use something like

from CBS screwed into the joining pipe and take a breather tube off that (preferably through a tip-over valve / one-way valve)

DaveFJ - 18/7/07 at 04:15 PM

now there's a thought...

The tank is connected to the filler by one of the rubberised fabric type tubes with the wire spiral running up it.... not sure that the connector you

show would seal down onto that?

cheers

RazMan - 18/7/07 at 04:47 PM

Yep, thats the type of fitting I had in mind - it should fit quite well imo. Just make sure you run the vent pipe as high as possible ot fillup time

will be messy.

DaveFJ - 18/7/07 at 04:58 PM

any pointers to where on their site I can find that?

cheers

tks - 19/7/07 at 11:00 AM

i dunno!

if you think in fluid pressures then

it doesn't make much sense because the low pressure pump sucks and with its output it just fills up the space wich it previously sucked away

result will be 0bars if you ask me!! the pump cant put out more fuel than it can suck in.

Because of the return tube it acts as a balance tube. In my opinion its not a problem if you would add to that hose a breather on the condition that

its higher fitted than the fluid level. (with your T piece easy archievable) think about the overall pressure in the tank. it will be everywhere the

same. And your pump is becomeing a circulating pump. and some times for a split second a LP pump.

what i would do is this!

weld from stainless a Y conection.

Connect the base of the Y to the tank

and devide each leg of the Y piece to the return line and to the breather.

the difference between an Y and a T is that in the Y the resistance for the fuel is lower and MUCH MUCH less fuell will be able to go up the other

leg. In fact i think that you can disconnect the breather while actuating the hole system. because of the suckment force of the LP pump the fuel will

be sucked back in to the tank.

just my 2p.

problem i see in the filler hose is that when filling it up at the gas station.

the aire needs to escape fast!! litres per second. Sow i think that its better archieved on that point then back to the fillerneck....so i would mount

an Y piece.

Tks

DaveFJ - 19/7/07 at 11:20 AM

Cheers for the input (love the word 'suckment':cool

The problem as I see it is if the flow from the LP pump exceeds the draw (minus return) from the HP side.... then there would be a constant overflow

of the swirl pot so the return pipe would be constantly flowing allowing no venting....

I am not woried about filling as i have a Unleaded reducer in the filler neck which has a series of holes around it for venting... Unfortunately the

cap itself is sealed so no venting through the cap when closed

cheers

Doofus - 19/7/07 at 01:05 PM

Dave,

As a temporary measure I have bodged my system exactly the same way as your first diag.

So far it's worked ok for a few thousand miles.

Idealy I'll put a new vent in the tank at the top so there's no chance of fuel getting near the NRV but what you suggested does work.

The NRV only lets air in to the tank on my system where you have "Vent"

Paul.

tks - 19/7/07 at 09:30 PM

quote:

Originally posted by DaveFJ

Cheers for the input (love the word 'suckment':cool

The problem as I see it is if the flow from the LP pump exceeds the draw (minus return) from the HP side.... then there would be a constant overflow

of the swirl pot so the return pipe would be constantly flowing allowing no venting....

I am not woried about filling as i have a Unleaded reducer in the filler neck which has a series of holes around it for venting... Unfortunately the

cap itself is sealed so no venting through the cap when closed

cheers

i know what you mean but if the hose from the Y to the vent is longer then the leg of the Y then the fuel wich 'blocks' the air vent route

will be pushed upwards to the vent then there will be a small buble in that hose and your system will have just vented!

Remember! that everything will move in the direction of the air flow- over pressure or unther pressure if air needs to be sucked in then it will be

sucked in and pass together with the fuel in the Y section.

if it needs to get out it will get out, generating a small bubble in the Y

Sow rule of thumb! the vent must be higher as the highest point in return line. i would add 100mm. (room for the bubble fuel).

Tks

DaveFJ - 11/1/08 at 11:31 AM

Solved my dilemas on this by suing a large rivnut and drilled through bolt, Just thought I would mention that I have used the Sierra (2.0Inj) fuel

tank breather!

Checked it and it is the sort that breathes 'in both directions' but closes when inverted. It is screwed to the side of the sierra filler

tube. All I did was cut away the plastic mounting flanges and mount it using a tywrap and mount high up under the rear wing

I knew it was a good idea to strip so much crap off the donor

tks - 13/1/08 at 12:43 AM

i'm gonna need the same!!

and i just was to post you using a rivnut.

Cheers,

Tks

or just a crap idea ??

or just a crap idea ?? or do i need to start looking at fitting a breather direct to the tank somehow?

or do i need to start looking at fitting a breather direct to the tank somehow?