As you said the return is to bleed off any air, brake line is big enough, I have a 0.8 mig nozzle in the rubber tube from the swirl pot return.

Description

In the process of plumbing in my swirl pot. I am running a returnless system, so all i have coming into the swirl pot is the low pressure pump feed. I

am struggling to find a position to put the overflow from the swirl pot back into the tank. However, i am running a Facet cube style pump for the low

pressure feed. These pumps are designed for running with carbs, which have a float chamber and shut off the fuel flow when this is full.

So, question is, do i actually need a overflow from the swirl pot back to the tank? I see no issues with just blanking this off and letting the low

pressure pump fill the pot up. Only issue could be a air pocket at the top of the swirl pot i guess?

If not, any easy ideas on getting a return connection into the tank? I was going to put it into the fuel sender, however it is too small to do so, so

that option is out!

I ran the return back to the tank breather outlet and made another breather.

As you said the return is to bleed off any air, brake line is big enough, I have a 0.8 mig nozzle in the rubber tube from the swirl pot return.

Description

Hi,

I would install a return hose anyway, even with a self-interrupting Facet LP fuel pump.

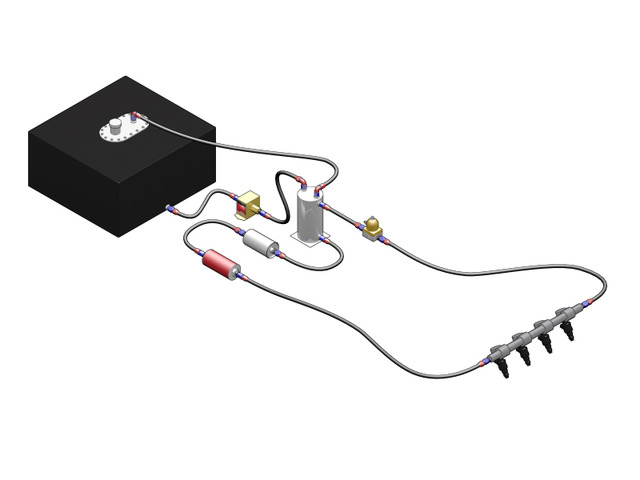

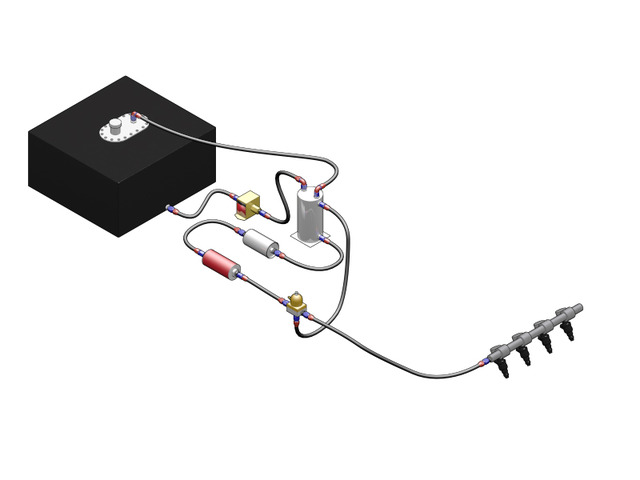

Here are some 3D schematics swirl pot installations I did a few years back when I was working for a company involved in hydraulic circuits for racing

cars. The difference between the 2 schematics is if you have a 2 or a 3 ways fuel pressure regulator.

Description

Description

Red cylinder = fuel filter

silver cylinder = high pressure fuel pump

golden cube = low pressure fuel pump

golden dome = fuel pressure regulator.

And I think it is pretty obvious where the swirl pot, the fuel tank and the interjection ramp are on the systematics

Hope that will help

The issue im getting is that i dont really want to drop the tank out and start drilling holes in it to get a fitting put in etc!

Now I'm not sure I understood your first post. Are you running an injection (high pressure) or carbs (low pressure)?

Injection, high pressure

quote:

Originally posted by ttalps2000

The issue im getting is that i dont really want to drop the tank out and start drilling holes in it to get a fitting put in etc!

If you run too large a return from the swirl pot the low pressure pump will run at 100% all the time.

I have plumbed in a similar system to yours on my car. I have a pressure regulator after the LP pump set at around 1 or 2 psi which gives the LP pump

something to work against. I also put a restrictor in the tank return line. I ended up at around 1mm IIRC. The LP pump still never actually stops

clicking but it is running a lot slower. The possible downside of this is that the swirl pot is slightly pressurised but this hasn't caused any

problems for me.

quote:Is this a problem? (genuinely dont know)

Originally posted by SPYDER

If you run too large a return from the swirl pot the low pressure pump will run at 100% all the time.

I don't know if it would be a problem with your pump either. I know that mine made a right racket if left running at full chat.

quote:

Originally posted by dhutch

quote:Is this a problem? (genuinely dont know)

Originally posted by SPYDER

If you run too large a return from the swirl pot the low pressure pump will run at 100% all the time.

quote:

Originally posted by rusty nuts

quote:

Originally posted by dhutch

quote:Is this a problem? (genuinely dont know)

Originally posted by SPYDER

If you run too large a return from the swirl pot the low pressure pump will run at 100% all the time.

40 Inches has already suggested a solution in his reply

used one of these in the end: https://www.parts4aircraft.com/fuel-tank-fitting-c2x9383165

Seems to work well and installed within 10 mins! Just hope it doesnt leak now!

Also added a 0.8mm mig tip to add some back pressure etc

quote:

Originally posted by ttalps2000

used one of these in the end: https://www.parts4aircraft.com/fuel-tank-fitting-c2x9383165

Seems to work well and installed within 10 mins! Just hope it doesnt leak now!

Also added a 0.8mm mig tip to add some back pressure etc

coated the drill in grease and caught the majority of it all. Pump and tank has filters to catch any small bits

quote:

Originally posted by ttalps2000

coated the drill in grease and caught the majority of it all. Pump and tank has filters to catch any small bits