What's going on with my boost then?

matt_gsxr - 26/9/11 at 09:37 PM

Quick question for you turbo experts.

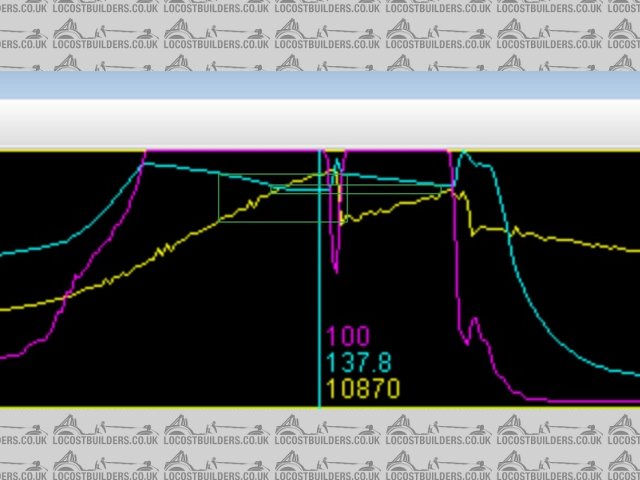

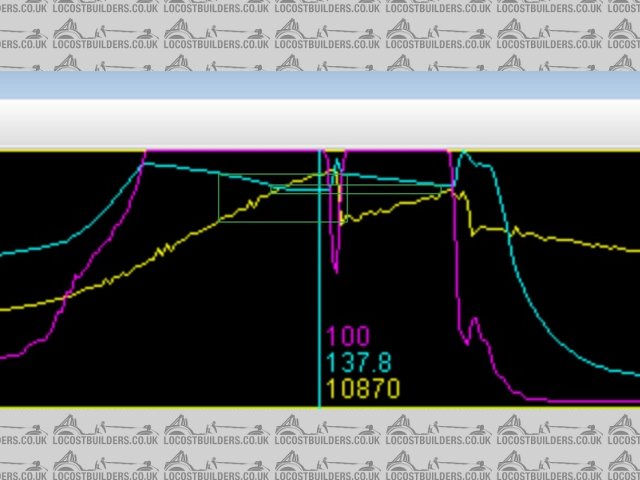

What is happening to my boost. I get some boost as low as 2300rpm, it peaks at 7krpm, where the boost controller is encouraging decent boost. Then

the boost gradually drops off with RPM. Is this expected? What is the mechanism?

I guess it is exhaust gas pressure pushing open the wastegate, but I'd like confirmation. I had the opposite phenomenon before, so opened up the

gas path to the wastegate (and the hole itself) a little.

My plan is to tweak the boost duty cycle at higher RPM to level off the boost (this can be controlled with megasquirt). Note that the controller is

inverted, i.e. 100% means don't bleed off any boost so it should just be based on the spring. Any (helpful) comments appreciated.

At the moment its a bit rich at the top end (aiming for a safe 11.5) and so I think I can get 8psi at 11kRPM without going over the duty cycle limits

of the injectors (s2000) at the present (3.25bar) fuel pressure. No idea on power, but its using a lot of fuel which must be a good sign  It

certainly feels quite nippy

It

certainly feels quite nippy

Matt

MakeEverything - 26/9/11 at 09:52 PM

Looks like where you have 'dipped' the throttle, it has opened the wastegate and is bleeding, hence the decline after the 'dipped'

TPS reading.

Boost so early on suggests an undersized turbo, but less lag. If you have enough top end, then i would leave it.

The other thing i would try and look at is a bleed valve for the wastegate, to try and adjust the actuator.

Antnicuk - 26/9/11 at 09:59 PM

can you clarify, with that turbo have you been able to maintain the boost at higher revs? if so, what did you do to it?

MakeEverything - 26/9/11 at 10:06 PM

quote:

Originally posted by Antnicuk

can you clarify, with that turbo have you been able to maintain the boost at higher revs? if so, what did you do to it?

quote:

Originally posted by matt_gsxr

I guess it is exhaust gas pressure pushing open the wastegate, but I'd like confirmation. I had the opposite phenomenon before, so opened up the

gas path to the wastegate (and the hole itself) a little.

I missed this until i scrolled down and read it again.

[Edited on 26-9-11 by MakeEverything]

matt_gsxr - 27/9/11 at 10:36 AM

quote:

Originally posted by Antnicuk

can you clarify, with that turbo have you been able to maintain the boost at higher revs? if so, what did you do to it?

I was getting boost creep. Basically the the boost continued to increase as RPM increased. In the figure below I had a 5psi spring and as you can

see as the RPM increase the boost goes higher. This will be mostly due to having a 2.75inch exhaust (super low back pressure).

So I did a bit of work on the turbo with my die grinder, to take it to this.

It might be that I have over done it a bit.

The turbo is a td04-16T and the engine is gsxr1100wp (at 1192cc), so pretty well matched. The 16T comes from a volvo T5R 850 which makes 240bhp has

2.3litre capacity and 6kRPM rev limit.

I am learning as I go along, but would prefer not to learn from my own mistakes!

[Edited on 27/9/11 by matt_gsxr]

matt_gsxr - 27/9/11 at 10:38 AM

quote:

Originally posted by MakeEverything

Looks like where you have 'dipped' the throttle, it has opened the wastegate and is bleeding, hence the decline after the 'dipped'

TPS reading.

Throttle dip is a gear change. I think the MAP vs RPM curves are the same before and after the gear change.

I think you are right regarding bleeding.

Thanks for your help,

Matt

cloudy - 27/9/11 at 10:44 AM

It is strange the boost doesn't plateau but actually drops untill you cycle the throttle - something that doesn't tie up with the wastegate

bleed. Perhaps it's the gas flow at the intake to the wastegate upsetting the rest of the flow to the turbo? Perhaps rounding the wastegate inlet

would help?

James

cloudy - 27/9/11 at 10:52 AM

Also, that said - the earlier graph you posted doesn't get to the same boost even after creep as the one with the problem, perhaps you are only

now seeing the limits of the turbo?

James

matt_gsxr - 27/9/11 at 10:55 AM

quote:

Originally posted by cloudy

It is strange the boost doesn't plateau but actually drops untill you cycle the throttle - something that doesn't tie up with the wastegate

bleed. Perhaps it's the gas flow at the intake to the wastegate upsetting the rest of the flow to the turbo? Perhaps rounding the wastegate inlet

would help?

James

There may be a slight confound of the boost controller. At low RPM (i.e. 7k) it bleeds of some of the pressure from the wastegate actuator. Above

that it plays not role (at the moment).

I don't really understand this stuff, but my gut feeling is that there is a difference between static pressure and this momentum effect.

The next step will either be to add in a stronger assist spring for the wastegate (basically stiffening things up), or use the boost controller to

bleed off some pressure. Either is easy, but I wanted to sanity check before blowing up another engine!

Matt

matt_gsxr - 27/9/11 at 11:49 AM

quote:

Originally posted by cloudy

Also, that said - the earlier graph you posted doesn't get to the same boost even after creep as the one with the problem, perhaps you are only

now seeing the limits of the turbo?

James

Boost seems to come back reasonably well. Maybe an optical illusion. Here I have added a couple of rectangles to guide the eye.

Description

cloudy - 27/9/11 at 12:05 PM

I meant the graph pre wastegate mod...

James

matt_gsxr - 27/9/11 at 12:30 PM

quote:

Originally posted by cloudy

I meant the graph pre wastegate mod...

James

Oh sorry, yes not sure about that one.

I was a bit cautious then about WOT, but it was certainly creeping and out of control, which was not a good thing.

It is very tempting to turn up the boost! 1atm has a nice ring to it.

matt_gsxr - 27/9/11 at 03:43 PM

Oh, here is a plot of the flow and pressure from the same log onto the compressor map.

Looks like it is pointing nicely towards a Pressure Ratio of 2.0 at decent efficiency.

Probably just need to be a bit braver and stiffen up the wastegate spring.

MikeRJ - 27/9/11 at 05:19 PM

Surely this would be expected since you are swapping between two different modes of operation? To start with you have a boost controller actively

controlling the wastegate to achieve a target boost level, which you then effectively disable at 7000RPM (why?) and leave the wastegate actuator to

look after things.

Using only the wastegate actuator spring to control boost rarely gives good results. In effect you have a control system where the wastegate actuator

provides an output movement which is proportional to boost pressure, but the wastegate itself will have a highly non-linear response that will depend

on numerous factors including engine RPM and load. A control system with only proportional feedback will always have a residual error term which

depends on the closed loop gain, and if that gain varies with RPM then so will your residual error.

Porting the wastegate will have the same effect as a large throttle body, i.e. most of the action happens in a smaller range of motion, making the

non-linearity worse. IMO the best solution will be to keep the electronic boost controller operating.

EDIT: Are you logging the boost pressure at the same point the wastegate is connected to?

[Edited on 27/9/11 by MikeRJ]

matt_gsxr - 27/9/11 at 08:15 PM

Thanks Mike,

I'm disabling the boost control at 7000rpm, because I had no idea how stiff my wastegate helper spring was, so didn't want the boost to go

too high.

Yes the pressure being logged is the same as is being fed towards the wastegate (but before the boost controller, so the wastegate will see less

pressure if the boost control is being used).

Thanks for your comments, very reassuring that the behaviour makes sense to you.

Matt

It

certainly feels quite nippy

It

certainly feels quite nippy