Sealing alloy airbox

matt_gsxr - 30/5/10 at 07:00 AM

Hi there,

Quick question: I'm just building an alloy airbox. I can't weld so I am riveting around the edges and it seems to be going together okay

but a few small gaps. What can I use to fill them?

more information:

The only thing is that there are some small gaps on some of the corners (1mm or less). I'd like to seal these, but not sure what material to

use.

I am popping (appropriate verb perhaps) a few additional injectors into the airbox as the plan is to run staged injection, so anything I use must be

stable when exposed to petrol (i.e. sikaflex is no good).

Could use JB weld, but wondering if there is something cheaper or more appropriate. Ideally that I can pick up from local car-spares, or Halfords

today.

Thanks,

Matt

afj - 30/5/10 at 08:16 AM

tiger seal or some instant gasket

[Edited on 30/5/10 by afj]

RazMan - 30/5/10 at 08:16 AM

quote:

Originally posted by matt_gsxr

must be stable when exposed to petrol (i.e. sikaflex is no good).

Sikaflex IS petrol proof - I've been using it as an internal petrol pump gasket for the last 3 years with no problems.

will121 - 30/5/10 at 09:43 AM

if you are more after pratically than assetetics could cover the joints in Aluminium foil tape like

this used to seal ventillation ducts but may depend on how much fuel

vapour you expecting? i would think as outer staged injectors only operate at top end it wouldnt be to much

matt_gsxr - 30/5/10 at 11:30 AM

I had read this thread

http://www.locostbuilders.co.uk/viewthread.php?tid=116541 which suggests Sikaflex not to like petrol.

I know there are different variants, so maybe that is the issue. Anyway, Tiger Seal is similar to Sikaflex (I think).

Agreed that it shouldn't see fuel, but with novel designs there is a good chance that things don't work in the same way as theory!

All good fun,

Matt

matt_gsxr - 30/5/10 at 02:42 PM

Sikaflex 221

from the datasheet:

"

Chemical Resistance

Sikaflex®-221 is resistant to fresh

water, seawater, limewater, sewage

effluent, diluted acids and caustic

solutions; temporarily resistant to

fuels, mineral oils, vegetable and

animal fats and oils; not resistant to

organic acids, alcohol, concentrated

mineral acids

"

I don't know what that means, but I don't like the sound of it. I will go with a thin seam of JB weld.

Matt

jimgiblett - 30/5/10 at 05:34 PM

I think there is a difference between being submersed in petrol and sealing an airbox. My airbox has sealed with Texflex (a PU adhesive similar to

Silkaflex and Tiger seal) for two years now without any problems.

- Jim

matt_gsxr - 30/5/10 at 11:01 PM

Thanks Jim, that makes some sense. I have some injectors in the air box (trying to get some of that extra cbr1100rr power from the old gixer), so I

may have more fuel in there than you! Obviously the intention is to get the fuel into the engine, but you can never be too sure with these things.

Anyway here area a couple of photos of progress.

Air_box_internals

And installed (temporary)

Air_box_installed

Yes, I know, you can't extend the fuel rail with duct tape (its to keep the crap out).

Ran out of consumables (riv-nuts) and the plexiglas cover needs recutting. Also need to sort out some sealant, will go for the PU stuff as

suggested.

Matt

jimgiblett - 4/6/10 at 11:05 AM

Nice bit of metal folding matt.

I would also spread a bit of PU over the rivets on the inside of the box (engine side of the filter). You wouldnt want any bits of rivet falling into

the engine.

- Jim

matt_gsxr - 6/6/10 at 08:44 AM

Good thinking Jim. I might actually swap them for gas sealed rivets, as these don't have anything to fall off. I just used Homebase rivets as I

had run out.

I will also need to insulate the airbox, as aluminium will get hot, which isn't part of the plan. The reason for aluminium is that it

doesn't burn.

Matt

scutter - 6/6/10 at 09:32 AM

Matt, If you can wait for a few days I'll pop into work and get hold of some aircraft spec fuel tank sealant?

ATB Dan.

matt_gsxr - 6/6/10 at 09:46 PM

Thanks Dan, that is great.

I have been running with it unsealed so that I can set up the megasquirt for the bigger throttle bodies (moved from gsxr600 to gsxr1000), so I can

certainly wait. Won't have much time this week as I have a le Mans trip on. So have to do 5 days work in 3.

Thanks, is there an Oxfordshire get-together soon? I lost track of the timetable.

Matt

scutter - 7/6/10 at 06:20 AM

I'll relocated a tube over the next week, I'll post a thread about a meet for the end of the month, Enjoy Le Mans.

ATB Dan.

matt_gsxr - 7/6/10 at 08:57 PM

Brilliant,

I haven't yet travelled to the Rose Revived in this car so I am really looking forward to it.

Thanks for your help,

Matt

Bluemoon - 8/6/10 at 09:22 AM

Not sure your plastic plexiglass end will be fuel proof?? Worth putting an offcut in a jar of fuel for a few weeks to see???

Looking with interest as I will be making a small airbox to sit on the top of my carb (not enough clearance for a filter but enough for a box and

pipe+cone filter under noise cone).. Need to figure out how to seal it... Could get the guys to weld it at work but I have had too may kitcar favors

to date!!

Dan

matt_gsxr - 8/6/10 at 10:22 PM

Dan,

I investigated this a little (actually I was helped), see this thread:

http://www.locostbuilders.co.uk/viewthread.php?tid=136684

So I think it should be okay.

The good thing, is that if it degrades with fuel then it will be nice and clear (or not, as the case may be!).

Matt

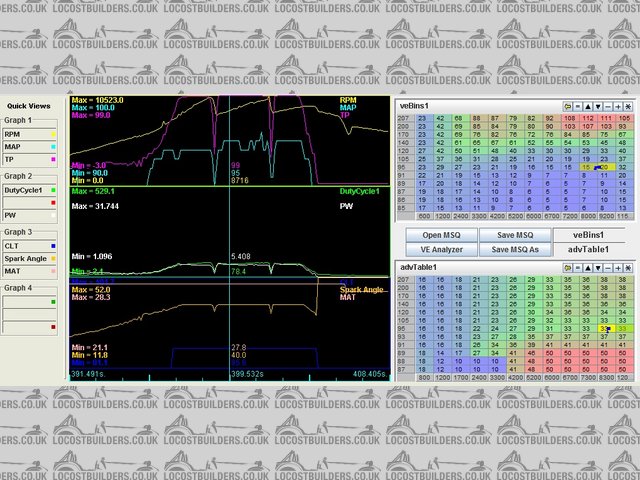

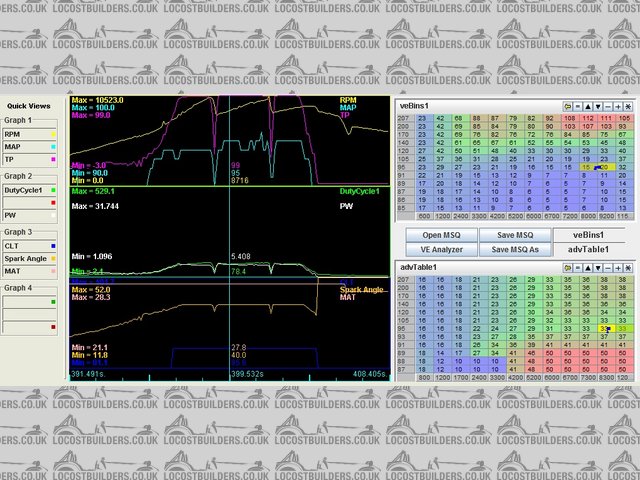

matt_gsxr - 21/6/10 at 10:34 PM

Airbox update

I built an inlet (using a Maplin sub-woofer trumpet at a cost of £2.69) mojnted at the front of the car and some 3inch hose plumbed into the

airbox.

ram_air_seen

I am using Alpha-N, so the MAP is just for interest. Note the MAP for these 3 different gears at WOT. As the speed increases the MAP gets a little

higher. Okay its only 1%, but that is about as much ram-air as you get at normal speeds.

I still need to lag the airbox and have replaced the old gsxr600 temp sensor with one that should suffer less from heat-soak.

All good fun,

Matt

matt_gsxr - 21/6/10 at 10:46 PM

Interestingly it looks like at 2 squirts per cycle that I will get to the maximum of the injectors. (presently I am at 87% at 10200 but the AFR is

14.1, and it revs to 11000).

I am pretty pleased with this, as I am led to believe that these are the same injectors (and pump) as used on a GSXR1000 and a GSXR1300, both of which

have decent power ratings.

The next plan is to go into TunerStudio and turn on the outer injectors.

Matt