Easimap Question

RazMan - 3/4/10 at 12:21 AM

I'm just getting to grips with tweaking my fuel map (only tickover so nothing dramatic) but it occurred to me that the data goes all the way up

to 12K rpm but my engine redlines at 7K. Is it a good idea to zero the injector data after the redline - a sort of last resort fuel cut?

matt_gsxr - 3/4/10 at 08:50 AM

I'm not sure.

THe problem would be that it interpolates between values, so if you have loads of fuel at 7k, and none at 8k, then you will be running lean at

everything above 7k.

I guess if you can move the mapping sites, then you can have a mapping site at 7001rpm and set that to zero, but it would be a bit harsh.

Most ECU have rev limiting built in, and cut in a more controlled fashion, so this isn't necessary.

This is also the way that Suzuki motorcycles do it.

I'd be interested to hear other views on this

Matt

Paul TigerB6 - 3/4/10 at 12:23 PM

quote:

Originally posted by matt_gsxr

I guess if you can move the mapping sites, then you can have a mapping site at 7001rpm and set that to zero, but it would be a bit harsh.

If you can move the mapping sites, its got to be better to close them up across the rev range to give more close control of fueling but particularly

around the area where you do most of your driving - say 2k to 4k rpm. The scale doesnt have to be linear on the ECU if you can set the mapping

sites.

Hope that reads properly

RazMan - 3/4/10 at 06:43 PM

The niggle for me is that the map just looks untidy, especially in 3D form. It would look a lot better and easier to edit on the screen with just the

relevant 0-7000rpm (or maybe 8K to allow for a bit of over revving)

I was hoping to set the rev limiter 'soft cut' to 6750 and the 'hard cut' to 7K - so an 8K fuel cut shouldn't get touched

anyway.

I can't seem to find a 'rev range' parameter anywhere in Easimap, but I can easily set rev limiter, fuel gain etc. Am I missing

something obvious?

atspeed racing - 10/4/10 at 03:07 PM

if your redline is at 7000rpm, just apply the same number to every cell in the next rpm step (example 8000) to "flat line" it.

the demand for fuel will start becoming less anyway, so if you do for whatever reason go beyond 7k, there will be plenty of fuel there - and as its

the same value, no problems with interpolations.

also an idea to do the same thing for ignition.

mbe does have a LOT of cells. so you could adjust it to suit your rpm band, but even with say 400rpm steps between sites, thats plenty for most

engines. (iirc 250rpm is what mbe uses by default?)

- colin.

RazMan - 10/4/10 at 11:38 PM

Thanks Colin, after some head scratching I was thinking along the same lines. I have adjusted both fuel and ignition in the same way as suggested. You

are right about the 250rpm intervals - loads of control with the MBE.

I have also decided to try a bit of map tweaking to compensate for my bigger throttle body & cams so I have ordered an Innovate wideband kit

instead of booking some dyno time. My reasoning is that the mixture can't be that far out so after a global 5% fuel increase (for a safety

margin), some datalogging should give me a good idea where I need to adjust fuel in the map.

Ideally I would like to use the lambda sensor to make the corrections but apparently the MBE is not easy to set up in this way. I have been looking

for some 'mapping for dummies' info with the MBE but strangely there doesn't seem to be anything.

[Edited on 10-4-10 by RazMan]

atspeed racing - 11/4/10 at 07:41 PM

mbe can be quite time consuming to map, simply because there is so much adjustment. it also works differently to alot of other systems. not my

favourite system to map thats for sure. but i have done quite a few, various road cars race cars, kit cars, car and bike engines.

i have some good maps for c20xe, 2litre zetec and hayabusa.

to get the map somewhere near right, i will typically concentrate on a few areas, and map in blocks. then interpolate between them... then once they

are close to right, i can go back and fine tune them afterwards. once you start getting a lump of the map correct, you can soon see a pattern forming

and know what the engine wants.

what engine is it?

- colin.

RazMan - 12/4/10 at 05:14 PM

I really appreciate the tips Colin

My engine is a 2.5 litre Duratec V6. I originally got it mapped in std form but have since fitted ST200 top end components so it breathes a little

better than before.

I have given the fuel a global 5% increase right across the map but I am aware that it will need to be remapped properly at some point. The cams will

push the power about 1000rpm further up so it might just need some tweaks to bring it right again. Daft question - Does the 'hump' just get

moved up 1000rpm?

I have ordered an Innovate LC-1 to monitor the AFR and I was thinking of datalogging a few key areas and basically changing the original fuel map on

the fly with a lot of testing with the LC-1 & laptop - as I said, the map shouldn't be too far off as far as fuel is concerned (not sure if

ignition needs to be tweaked though)

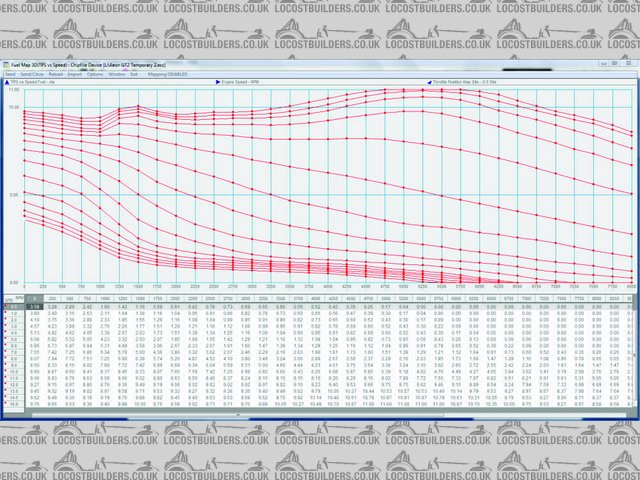

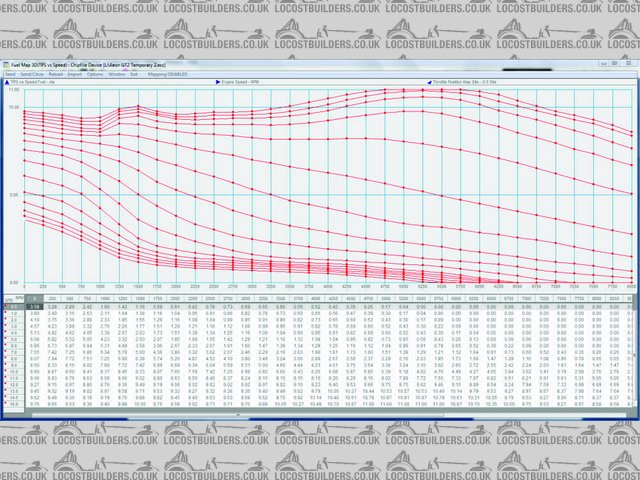

Here's a pic of my old map if it helps explanations - *edit* silly me that's the dyno graph, I'll try and get a pic of the map later

[Edited on 12-4-10 by RazMan].jpg)

RazMan - 12/4/10 at 05:30 PM

Tada!

Rescued attachment Map.jpg

atspeed racing - 12/4/10 at 07:06 PM

cant see the pics on my laptop.

it would be an idea to remove a bit of ignition at WOT - at least until you get the car on the dyno.

adding a bit of fuel across the board could be an idea too. a richer mixture takes longer to burn than a leaner mixture, so has the same effect of

running less ignition timing. this will also lower cylinder pressures so will keep you further from the det zone.

the "bump"will move, but the whole pattern may also change. may want less fuel lower down, but more higher up for example.

- colin.

RazMan - 23/4/10 at 11:51 AM

I'm now playing with my LC-1 Lambda kit but I am not sure which of the analog outputs to hook up to the MBE 970.

Analog 1 is 1.1V = 14 AFR and .1V = 15 AFR. This is a simulated narrowband signal.

Analog 2 is setup as 0V = 7.35 AFR and 5V = 22.39 AFR.

I am not going to be mapping - just using Easimap to act as an AFR gauge to get a rough idea of any rich/lean spots. Any ideas?

RazMan - 24/4/10 at 06:51 PM

Apparently its the 0-5V which talks to the ECU

atspeed racing - 1/5/10 at 09:40 AM

yea it will be 0-5v...

why not just use the lc1 as your gauge rather than trying to wire it into the mbe?

RazMan - 1/5/10 at 03:09 PM

Ah well, when I ordered the LC-1 I forgot about a gauge so I initially thought that I could use the laptop until a gauge was found (its on the way now

as it was delayed with all the Icelandic volcano stuff)

The trouble is that I would need two laptops to have Easimap AND the LC-1 live at the same time. So I thought i would play with the inputs for a

while and see what happens.

I have since found that calibrating the Easimap AFR reading is very long winded so I have decided to wait for my gauge and calibrate it with that.

This mapping lark is a bit involved innit! After all this I will probably end up getting it mapped by a professional but at least I will have a pretty

gauge to look at

atspeed racing - 6/5/10 at 08:42 AM

lol

i do it everyday

- colin

RazMan - 22/7/10 at 03:59 PM

Update:

I have been having a whole load of fun with my AFR gauge  Over the last few weeks I have been tweaking the map in various ways, getting the AFR to

about 13:1 under power and 14:1 on light throttle. The difference is quite noticable and power is definitely increased.

Over the last few weeks I have been tweaking the map in various ways, getting the AFR to

about 13:1 under power and 14:1 on light throttle. The difference is quite noticable and power is definitely increased.

I now want to take it one stage further and get Easimap to do some datalogging and possibly use the wideband signal to continually trim the fueling -

it just seems to make sense in my mind.

So, connecting up the 0-5V output to the ECU is fairly straightforward (I assume I can tee off the gauge input) but how the hell do I tell Easimap to

switch it on? I can probably calibrate it using my LC-1 and gauge but how do I do that? I usually consider myself quite adept when it comes to stuff

like this but I have to admit I am completely stumped

Any pointers chaps?

[Edited on 22-7-10 by RazMan]

dlatch - 23/7/10 at 04:59 PM

won't easimap connect to the ecu and receive its data from there?

i would not go splitting outputs from the wideband don't think it will provide accurate info, not really sure what you trying to do exactly

output 1 to guage only

output 2 to ecu

RazMan - 23/7/10 at 07:43 PM

Just being a bit geeky I suppose

The gauge requires 0-5V as it states in the LC-1 handdbook (its working fine) so that only leaves the 0.1-1.0V free.

I just want to do some fine tuning on the map and switch on the Lambda section of Easimap. Some datalogging would be good as well because trying to

keep an eye on the gauge on the road can be a bit ... er .... challenging at WOT

So are you saying I can have either gauge or Lambda tuning but not both?

dlatch - 23/7/10 at 08:47 PM

won't the guage give you a accurate reading using the simulated narrowband output ? have you tried it?

i think the output is for normal guages which work on the narrowband sensor voltage.

if your datalogging then the ecu needs the full wideband output for sure

besides how can you look at a laptop and a guage and drive?

RazMan - 23/7/10 at 10:57 PM

quote:

Originally posted by dlatch

won't the guage give you a accurate reading using the simulated narrowband output ? have you tried it?

i think the output is for normal guages which work on the narrowband sensor voltage.

No, the gauge requires the 0-5V to give the full range (7.7 - 22.9 IIRC) and as you say, only a basic gauge (rich or lean) will take the other output

AFAIK.

quote:

Originally posted by dlatch

if your datalogging then the ecu needs the full wideband output for sure

besides how can you look at a laptop and a guage and drive?

That's the problem - at the moment I am perching the netbook next to my AFR gauge and trying to squint at both while on the move. One of these

days I am going to end up in a hedge, especially when mapping the upper rev range

At least with the data logging I can view the data from the safety of my desk computer, make some tweaks and then download to the netbook to carry on

the process. I suppose I could put a changeover switch for the gauge / ecu and get the best of both worlds.

dlatch - 23/7/10 at 11:49 PM

has the mbe software not got real time tuning?

so you could get a assistant to drive while you tune?

thats got to be the best way and certainly my plan for mine

RazMan - 24/7/10 at 10:33 AM

Ah well you are then in the world of the mapping box, which is very expensive and not really worth getting unless you are a professional tuner.

AFAIK the only 'real time' function is the Lambda input, which returns us to my earlier question - How do I calibrate it and switch it on?

atspeed racing - 27/7/10 at 11:38 AM

remember we are only hour or so down the road from you if you want to try your MBE set up on our dyno.

- colin.

http://www.atspeedracing.co.uk

[Edited on 27/7/10 by atspeed racing]

RazMan - 27/7/10 at 05:15 PM

I didn't realise you were so close to me Colin.When I get my ITBs sorted and bigger injectors I will definitely come down and see what you think

of my DIY map

.jpg)