correct suspension setup!?

Johneturbo - 22/7/08 at 05:55 PM

I've done a fair few miles with the car now, and i know it might take a while for it to settle, but i feel like the front of the car just skips

over bumps at any decent speed on B roads (ie 60mph)

no matter what i try with the adjustment on the front shocks its the same.

the car has been fully laser tracked with 0 front toe to make it a bit more bearable and 1.5 neg front camber, as in the set up instructions.

i've tried different tyre pressures, i'm now on 15psi all round.

i'm at a loss really with what to try and knowing if this is normal, i've driven cars with hard suspension before, but it feels like there

is no give at the front at all.

there is no delfection at the front if i push down on the front of the chassis, is this a trait of inboard suspension?

any advice would be great

[Edited on 25/7/08 by Johneturbo]

coozer - 22/7/08 at 05:57 PM

Have the shocks got plenty travel left or are they riding on the bump stops?

CRAIGR - 22/7/08 at 05:58 PM

What poundage springs are they John????

mr henderson - 22/7/08 at 05:59 PM

Sounds like the springs are far too stiff (as they frequently are in LSIS's)

Do you know what the spring rate is?

John

TimC - 22/7/08 at 06:11 PM

I had the same thought on spring rates as Mr H. In comparison, mine deflects relatively well in the static position. Is it possible that you have

CEC-spec springs rather than BEC-spec?

miikae - 22/7/08 at 06:13 PM

On my RH S7 i have inboard Gaz shocks and 130 lb springs and tie bars , (ARB thrown away ), suspension works great now , sounds to me that your

springs are far too stiff , what poundage are they ?

Mike

mookaloid - 22/7/08 at 06:21 PM

As above - springs too stiff

worX - 22/7/08 at 06:26 PM

Hi John'

What ride height are you running front and rear?

What's the poundage of the springs front and rear?

What setting do you have the shock absorbers on, all round?

What uprights do you have on the front?

Steve.

Mark Allanson - 22/7/08 at 06:31 PM

Static zero toe will give you toe out when in motion - problem solved!

I have 30' static toe in and the ride is superb

Paul (Notts) - 22/7/08 at 06:33 PM

First thing I would check in this situation is whether the front wishbones move freely on the bushes.

Disconect the shock with the front end jacked up ( wheel removed ) and check the wishbones are free to move.

Had the same problem at first with my Viento. Turned out to be a problem with the bushes and crush tubes.

Paul

Davey D - 22/7/08 at 06:41 PM

i noticed that it is quite hard on mine, but never thought anything of it, as i havent seen anyone else bring it up until now, and i also havent yet

driven the car to know how it rides.

mine is so hard that if i remove the nose cone, and stand on the frame at the front, and jump up and down, the suspension barely moves

Johneturbo - 22/7/08 at 06:44 PM

Ok guys first of thanks for the replys, it's nice to know help is out there

i've taken a few pics and i'll try ans answer the Qs

the front springs are 175

i've tried all the settings on the shocks to no effect really.

front uprights are mnr cortina type.

ride hight is front 150mm

rear about 165mm

i can't get the front much lower as the springs are near the platforms and the pushrods are fully wound in

if i jack the car up the suspesion does droop down, but i will check the bushes as another thing to try.

here's some pics as it sits

Rescued attachment 22072008463.jpg

Johneturbo - 22/7/08 at 06:45 PM

.

Rescued attachment 22072008464.jpg

Johneturbo - 22/7/08 at 06:45 PM

.

Rescued attachment 22072008466.jpg

Paul (Notts) - 22/7/08 at 07:03 PM

You should be able to bounce the front end up and down. I can do mine even with 300lb springs on the front and back!

Paul

mr henderson - 22/7/08 at 07:08 PM

quote:

Originally posted by Mark Allanson

Static zero toe will give you toe out when in motion - problem solved!

I have 30' static toe in and the ride is superb

Are you serious, tune the ride by adjusting the toe?

John

MikeR - 22/7/08 at 07:20 PM

i've got 220 (or is it 240lbs) springs with a crossflow engine, when i stand on the chassis and bounce i can watch the wheels angle inwards and

the car body drops (made me smile the first time i saw it).

Paul (Notts) - 22/7/08 at 07:27 PM

Dont know anything about inboard suspension set up so ignore my thoughts ...

Something must be too tight to move you would be able to move the front end.

+ seems a big difference in moment of A compared to B - I would have expected it to be the other way round...

As I said ignore my thoughts as I dont have an MNR or inboard suspension set up

Paul

mr henderson - 22/7/08 at 07:30 PM

As Paul points out, the force required to move your wheels up and down is much higher than the 175lbs required for an inchof movement at the

springs.

Obviously you need to check for something making the suspension reluctant to move, but if no fault is found then you are off to the spring shop

John

mark chandler - 22/7/08 at 07:40 PM

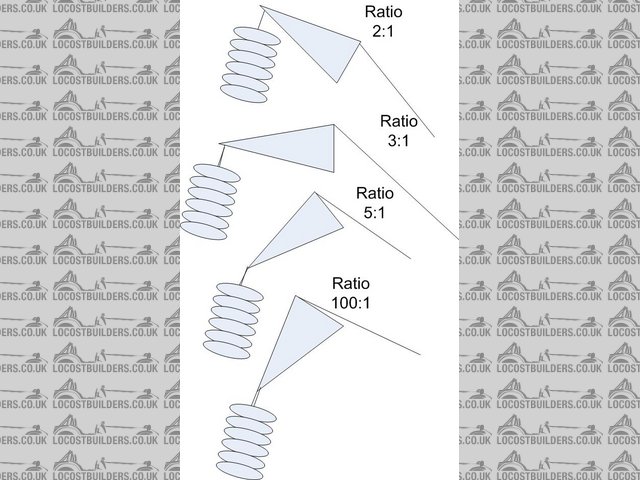

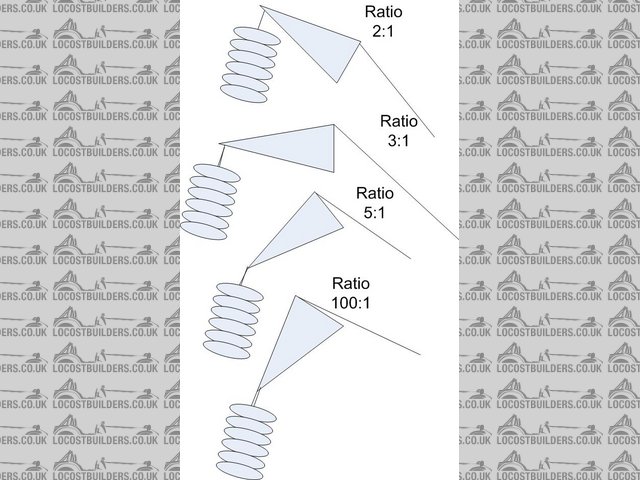

That triangle changing direction of the movement must be gearing you shock up 3:1 maybe more as its past right angles so the amount of energy to move

increases even more, your 175lb springs are effectively 525lb. Thats your problem!

So you need less manly springs, and in the ideal world try and shorten the rod from the wishbone up to this to stop it going over centre.

Here's a crude drwaing hopefully showing what I am on about

[Edited on 22/7/08 by mark chandler]

Rescued attachment drawing1.jpg

mikeb - 22/7/08 at 07:46 PM

heh lots of advice,

I concur with the last post.

Using a bell crank for the inboard shocks will give you a rising rate shown by the ratio increasing with suspension movement in the last diagram.

If you have the spring and damper rates as for an outboard setup you'll be way to stiff might want to check what you asked for when you ordered

your coilovers. you should be able to bounce on the front and get some movement.

Just a note why does everyone stiff refer to spring stiffness in pounds? I though we'd been metric for a few decades now (Nm) but saying that my

springs came with force in pounds.

[Edited on 22/7/08 by mikeb]

Johneturbo - 22/7/08 at 08:18 PM

Paul/Mark

i did wonder about the angle of the rocker, thats why i posted a pic of it.

my problem is the pushrod is as short as possible and my lower wishbone is still a nats wisker below horizontal.

so i've had to drop the springs down to get it as close as possible, but then that's made the rockers sit a lot lower than ideal i

guess!?.

maybe a solution would be shorter pushrods?

stuart_g - 22/7/08 at 08:24 PM

My suspension is exactly the same as yours John and I have the same problem.

I was told to set the car up slightly different to the geometry in the build manual.

-1 to 1.5 degree camber all round.

1mm toe in all round.

This will not make any difference to the suspension not moving though. It does seem very hard.

Andy W - 22/7/08 at 08:34 PM

which way round is the bottom wishbone, is the push rod mounted on the top or bottom of the bone? this will alter the angle of the rocker

Andy

David Jenkins - 22/7/08 at 08:39 PM

I'm with Paul (Notts) - that poundage, with that ratio, would make for a huge spring rate. My conventional (external) coil-over setup uses 180lb

springs, and I consider them to be as stiff as I'd want - no more.

If that does work out to over 500lb spring rate then it's WAY too high!

Perhaps you should talk to MNR as other people say that they're happy with this setup, which suggests that something's amiss with yours.

Johneturbo - 22/7/08 at 08:45 PM

Pushrod is on top now so that the circlip is facing down, due to my bearing pulling out the other way.

Stu it's not a tracking thing it was the same before i got it 4 way laser tracked.

the shocks are not doing their job or not being allowed to.

if i jack the car up and disconnect the pushrod i can move the wheels up and down freely.

Agriv8 - 22/7/08 at 08:54 PM

HI chaps,

Rug rat is teathing so I have about 1 1/2 minutes before the screams start to make my ears bleed.

rocker look too far rotated to me but could be wrong.

So I would

Test 1

Disconect the push rod from the bottom wishbone ( easiest one to disconect !) and see if the upright moves freeley ( ie through its bump and droop )

this will check that all the joints are free .

If yes

Test 2 ( while disconected from the bottom wishbone )

Disconect the shocker from the rocker and check that the rocker moves freely ( check that non of the bearings have nipped up )

I know Mark is too and fro with SVA's this week but I'll see if I can get a message through to him tomorow.

oh report back with findings

Right off to administer Calpol

regards

Agriv8

edited to add just joney turbo reda you last post so miss test 1

[Edited on 22/7/08 by Agriv8]

Andy W - 22/7/08 at 09:16 PM

With my circlip on the bottom, pushrod is also on the bottom

Andy

jacko - 22/7/08 at 09:17 PM

quote:

Originally posted by Andy W

which way round is the bottom wishbone, is the push rod mounted on the top or bottom of the bone? this will alter the angle of the rocker

Andy

I'm with Andy on this one the wishbone bolts on the push rod go under the bone

thats what they were like on the demo car at newark show

[Edited on 22/7/08 by jacko]

Andy W - 22/7/08 at 09:20 PM

Andy

jacko - 22/7/08 at 09:26 PM

Will this help SNAP

New Nose Front

[Edited on 22/7/08 by jacko]

JoelP - 23/7/08 at 06:27 AM

job done, thats your problem. Compensating for the extra 2 inches of suspension height is taking the rocker to deep into rising rate territory.

stuart_g - 23/7/08 at 07:48 AM

quote:

Originally posted by JoelP

job done, thats your problem. Compensating for the extra 2 inches of suspension height is taking the rocker to deep into rising rate territory.

Not the case I'm afraid. My bones have the pushrod mount on the bottom and my suspension is also solid.

RickRick - 23/7/08 at 07:49 AM

is it not the case that people including me are fitting the wishbones with the push rod mount at the top, to gaurd against any chance of the circlip

locating the bearings failing?

having said that, my cars ridehight is currently to be measured in feet, as i just wound the springs up as much as i could before i put it on

it's wheels, and i guessed at the pushrod a few turns out each end, and i'm sure there's some movement in the suspension when i bounce

it

TimC - 23/7/08 at 08:04 AM

I had a look at mine last night having just flipped the 'bones over as per the safety advice. As a side note, I'm not convinced that this

isn't an unnecessary compromise and will get some advice on whether a new pair of bottom wishbones will serve me better. After all, it does seem

that the geometry is designed to have the push-rod mount on the bottom.

In terms of my rocker, as it stands, the pivot for the pushrod and that for the damper are at roughly equal heights so if you draw a line between the

centre of the two bolts, this line will be more-or-less parallel to the floor. Hence using Mark's multiplier diagrams, I'm somewhere

between 2:1 and 3:1. I do have a little droop at the front so need to wind the pushrods out a bit, which I guess will take me closer to 3:1.

Now, people need to bear in mind that I have 13s and modestly side-walled slicks but my lowest chassis rail at the front is only 100mm or so from the

floor. Also consider that my chassis is different to most others so I'm not sure what difference that makes.

We need Mr Nordon's input me thinks.

marc n - 23/7/08 at 09:03 AM

appologies

i havent received any emails so i think my email must be on the blink again

im just leaving for sva i havent read it all but breifly

1. john i have had a quick look at some of your build pics and the front uprights are on upside down ( not sure when the photos where taken so you may

have rectified this ) so you could be experiencing balljoint lockout

2. the 175lb springs are what are fitted to the complete car we have here and with dampers on a soft setting i can jump up and down on the front end

and get plenty of movement nearly to the bumpstop

3. possible causes for very stiff front end

1. balljoint lockout

2. incorrectly valved dampers

3. incorrectly marked springs

to check springs please count number of coils and measure the diameter of coilspring wire

and i should be able to check with what we have here

if springs tally up then it can only be dampers

should be back by four so will check back in then

also if somone could do me a favour and send a test email just to make sure its working

cheers

marc

Gergely - 23/7/08 at 02:32 PM

Test email sent as I have also sent you a question two days ago.

Johneturbo - 23/7/08 at 03:23 PM

Hi Marc thanks for getting back to me.

your right, in that pic they are upside down, but that was only a temporary thing!

i've just had a count of the coils they are 10 including the half ones top and button.

when you say measure the spring do you mean the thickness of the coils? if so they are about 1cm ish.

anything else you want me to check, let me know.

cheers

john

[Edited on 23/7/08 by Johneturbo]

Johneturbo - 23/7/08 at 03:31 PM

TimC how do your lower wishbones sit? are they horizontal or just above?

now i've turned my lowers over, mine is just a bit below which i guess isn't ideal?

i've wound the springs almost down as far as they will go.

the only sulution i can think of is.

new wishbones with mount and circlip under

or shorter pushrods.

to get the rocker more level.

TimC - 23/7/08 at 03:41 PM

quote:

Originally posted by Johneturbo

TimC how do your lower wishbones sit? are they horizontal or just above?

now i've turned my lowers over, mine is just a bit below which i guess isn't ideal?

i've wound the springs almost down as far as they will go.

the only sulution i can think of is.

new wishbones with mount and circlip under

or shorter pushrods.

to get the rocker more level.

My wishbones are not quite parallel to the floor with the rose joint connected to the chassis brackets slightly lower than that connected to the

upright.

On your new wishbone comment, don't you mean circlip on top and pushrod mount under?

Johneturbo - 23/7/08 at 04:14 PM

quote:

Originally posted by TimC

quote:

Originally posted by Johneturbo

TimC how do your lower wishbones sit? are they horizontal or just above?

now i've turned my lowers over, mine is just a bit below which i guess isn't ideal?

i've wound the springs almost down as far as they will go.

the only sulution i can think of is.

new wishbones with mount and circlip under

or shorter pushrods.

to get the rocker more level.

My wishbones are not quite parallel to the floor with the rose joint connected to the chassis brackets slightly lower than that connected to the

upright.

On your new wishbone comment, don't you mean circlip on top and pushrod mount under?

Hi Tim

no, the circlip was on top that's why it pulled out, it needs to be under.

I hope you've not turned yours over so the circlip is now on top!

[Edited on 23/7/08 by Johneturbo]

TimC - 23/7/08 at 04:25 PM

B**l*cks!!!!! I'm a pillock.

Well, sorry John, this won't help you but I think I'm sorted - just need to swap the bones back over! Oh, well, I'll be an expert at

it now!

Johneturbo - 23/7/08 at 04:31 PM

Stop watch at the ready!

stuart_g - 23/7/08 at 04:40 PM

I was told that I didn't have to turn the lower bones over and to leave the circlips on top.

This doesn't solve the problem of very stiff front suspension though. I have my rockers almost horizontal and have just jumped up and down on the

chassis at the front and the suspension barely moved.

marc n - 23/7/08 at 05:57 PM

im at home now, but can check tomorrow ref springs, if the suspension is moving freely minus connection to shocks and springs then then it can only be

either of those, as i say we have a 06 r1 car full car minus body and lights built up with 175lb spings and it compresses and returns lovely, in my

mind its got to be incorrectly marked springs ( im pretty sure protech wouldnt have got the valving wrong as they have done so many )

john did you get my email ref diffs etc

cheers

marc

marc n - 23/7/08 at 06:00 PM

a breif explanation ref rocker design

1. made this way to exploit the full travel of the damper rather than a small portion

2. to allow a reasonably soft compliant car at road speed and when the car is pushed harder as in trackday a harder front end

cheers

marc

Johneturbo - 23/7/08 at 10:17 PM

Marc

just checked emails last one i got from you was wednesday 16th, you said you had one to check, and was going to let me know.

cheers

john

TimC - 24/7/08 at 06:12 AM

quote:

Originally posted by marc n

a breif explanation ref rocker design

1. made this way to exploit the full travel of the damper rather than a small portion

2. to allow a reasonably soft compliant car at road speed and when the car is pushed harder as in trackday a harder front end

cheers

marc

Yes, that makes sense, but Mark Chandler's drawing is good too, so is John's pushrod too long since he's clearly not able to use much

of the travel of the damper as it stands?

I'm just trying to understand what a correctly adjusted rocker set up should look like.

marc n - 24/7/08 at 10:35 AM

everyone should have had an email approx 3 weeks ago ref length of pushrods, those who have turned their wishbones over have got new pushrods here on

the shelf waiting for them, just need an email to confirm adresses etc

yours tim will be fine as you have the wishbone other way around

checked spings here they should have 10 coils including halves at 8mm dia

john sent emails to the john@johneturbo.com address

anyone who needs to contact me its much quicker and easier to email me as my phone can pick up the emails ( i have been at the workshop 1 day this

week due to sva tests so i dont get time to get on locostbuilders )

cheers

marc

Johneturbo - 24/7/08 at 02:39 PM

Hi Marc

That email addy has be dead for 2 years now.

i'ts .co.uk

the same one i've been emailing you with,since i first started the build!

so your springs there are the same as what i have here. does that elimnate the springs being the problem? is there anyway i can check the shocks?

cheers

john

edited to say, i'm off work tomorrow marc, so will be down in the garage all day going over the car. so if you get a spare 5mins to call that

would be great

07861668823

[Edited on 24/7/08 by Johneturbo]

procomp - 25/7/08 at 06:51 AM

Hi easiest way of checking the dampers/shocks.

Unfortunately the first step is to remove them from the car and then remove the springs.

Then with the dampers on ZERO clicks you should be able to move them by hand in / out without to much trouble. If you then go through the click range

you should get as far as 6 or 7 clicks ( 13 clicks max ) before they are some what of a strain to push/pull in and out ( depending on how big your

muscles are of course  ).

).

For the problem to be the dampers they would have to be unable to move in / out by hand on ZERO clicks.

Only last check before removing them is they are wound to ZERO click on the car IE they are fully ANTI CLOCKWISE.

Cheers Matt

stuart_g - 21/8/08 at 09:21 AM

Last night I changed the 175lb front springs to 150lb springs, What a difference. I went out for a drive down a road which I couldn't go fast on

before but now I can see the suspension working and the car is a lot more controlled. I set the adjusters to 6 clicks in from fully wound out as a

start point and it seemed to be perfect.

I still have some testing to do on some other roads that I found difficult before but first impressions are excellent.

The front suspension is still hard enough not for it to be too soft if you see what I mean, but not as hard as before. I couldn't get the front

suspension to move before even when I stood on the car but now when I stand on it and bounce up and down the suspension moves a lot more.

I still need to have the car professionally set up and corner weighted but I am very pleased with the outcome so far and I think the softer springs

are more suited to the crappy road conditions we have. I dare say that if the car was a track car only the 175lb springs would have been fine.

Of course this is my personal preference to how I want the car to feel and may not be suited to everyone.

Cheers

Stu.

Davey D - 21/8/08 at 03:23 PM

Stuart - Did you change the back springs, or leave the original supplied ones in place? Where did you get your new front springs from, and how much ££

?

stuart_g - 21/8/08 at 05:22 PM

quote:

Originally posted by Davey D

Stuart - Did you change the back springs, or leave the original supplied ones in place? Where did you get your new front springs from, and how much ££

?

Didn't change rear springs. New front springs supplied by MNR. Give Chris a call for pricing.