RK

|

| posted on 9/10/08 at 01:27 AM |

|

|

dash to scuttle issue

I don't have a pic right now, but I will try to explain:

My scuttle is fibreglass, from Kinetic in the US. I had widened it to fit my frame. I don't know why it came too narrow in the first place. NOW,

I have come to mount a dash and have noticed an incredible curving of the dash (concave when looking at it) that looks very bad. I see one of two

options:

1. cut 1/2" off the the rearward part of the scuttle so the dash has a flat surface to mount to. I may need to make ally tabs to glass into the

scuttle so the dash can mount.

2. cut my losses (time mostly) and buy a properly made one that fits. Problem: costly from the UK but may do it anyways.

I had an 11" high version to better fit my engine, but I can always cut big scoops in the bonnet for fitting over the engine.

I also have a very long (40" gap between the edge of the scuttle and the nosecone. This is 6" at least longer than the bonnet I just

bought (and can't return). I am sure I can fill the space with something. It is also made for a 10" high scuttle. The frame is MK. gap between the edge of the scuttle and the nosecone. This is 6" at least longer than the bonnet I just

bought (and can't return). I am sure I can fill the space with something. It is also made for a 10" high scuttle. The frame is MK.

Thanks again boys and girls. As usual, it is always appreciated when someone comes on and gives good advice!

[Edited on 9/10/08 by RK]

|

|

|

|

|

skodaman

|

| posted on 9/10/08 at 05:05 AM |

|

|

Why not make a scuttle out of metal. Imho they look much better than the glassfibre ones. Also you can keep it fairly flat which makes it easier to

get a screen cut to fit.

Skodaman

|

|

|

Paul TigerB6

|

| posted on 9/10/08 at 09:06 AM |

|

|

Which part has gone concave?? I managed to flatten out a warped scuttle panel by applying heat to it to soften it (using an Infra Red patio heater)

and then pushed the warping out with plenty of weight placed on it before allowing to cool.

Hope that makes sense??

|

|

|

RK

|

| posted on 9/10/08 at 12:48 PM |

|

|

The part the dash mounts to is bent 1/2" concave. The glass is very thick and I sincerely doubt I could get it to bend, but it's a good

idea to keep in mind!

Has anyone made one out of square tube ally skinned with ally? This can be rivetted together. Has anybody had experience bending square tubed ally?

The round tube can be bent fairly easily if you take you time.

Can one buy the metal ones from Caterham? Low cost went out the window a long time ago.

More ideas welcome!!

[Edited on 9/10/08 by RK]

|

|

|

Triton

|

| posted on 10/10/08 at 01:49 PM |

|

|

RK,

Sounds to me you would be better skimming the scuttle in filler to get the shape you want then take a mould from it or even use it as a buck to form

one from ali sheet.

We do a Locost scuttle that fits the 42" wide chassis but like you say it's the cost of getting things from the UK that make it daft...

Mark

My Daughter has taken over production of the damn fine Triton race seats and her contact email is emmatrs@live.co.uk.

www.tritonraceseats.com

www.hairyhedgehog.com

|

|

|

907

|

| posted on 10/10/08 at 04:26 PM |

|

|

Hi RK,

I made my scuttle from 25 x 25mm box and sheeted it with ally.

It bolts onto the chassis with 4 m8's.

(It still has the white plastic coating on in the pic below.)

Happy to run through how I did it should you wish to make one similar.

At least when you make stuff you can make it to fit.

ATB

Paul GImage deleted by owner

|

|

|

RK

|

| posted on 10/10/08 at 04:31 PM |

|

|

That looks more like it! Triton's method is way over my head. I much prefer the metal look anyways.

|

|

|

RK

|

| posted on 10/10/08 at 04:50 PM |

|

|

How thick does the ally or steel sheet have to be? I have found it difficult to get large 4' x 8' sheets - they don't fit in the

car! But, a local building supplier sells large sheets of .5 mm steel ones that can be rolled. I will need something at least 52" long.

|

|

|

907

|

| posted on 10/10/08 at 07:01 PM |

|

|

Hi RK

Firstly, ignore the material I've used, (stainless) and use 25mm box and 1.5mm ally or 1mm steel to clad it.

A 6x3' should do it. (2m x 1m)

By far the hardest bit are the corners of the frame.

I cut 2 rings from 1.5 sheet and 2 strips.

Tack a strip around the o.d. of the 1st ring.

Tack the 2nd ring to the outside strip.

Form the 2nd strip into a circle and tack it to the i.d. of the 2 rings.

You should now have a hoop of square box.

Weld all 4 edges and clean off the welds.

Cut into 4 equal pieces.

You now have four 90deg box section bends.

Make up your scuttle frame using these bends and straight lengths of box.

The dash end is larger than the bulkhead end so that it slopes, in line with the bonnet, down to my nosecone.

What do you think?

Paul G

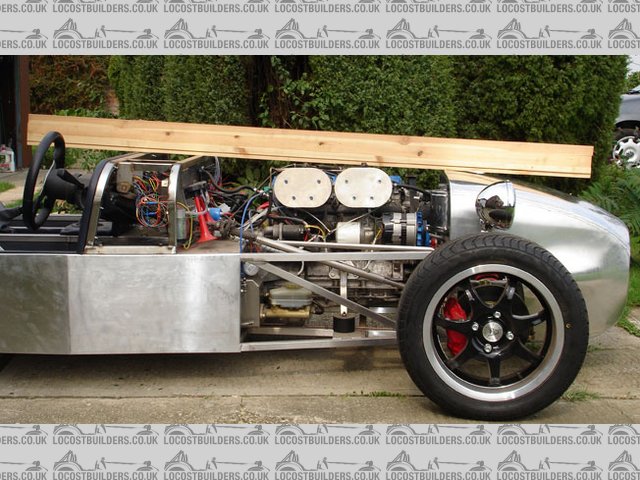

Rescued attachment scuttle-frame.jpg

|

|

|

907

|

| posted on 10/10/08 at 07:19 PM |

|

|

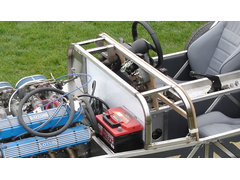

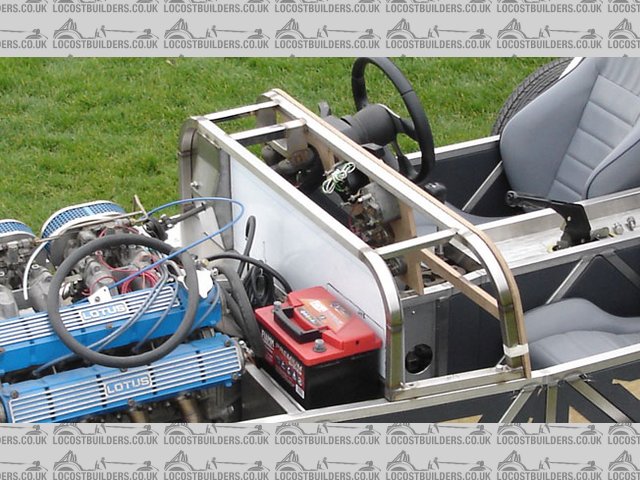

This pic was taken when the "spaghetti" had been added.

(Electrics have never been my strong point.  ) )

It shows what I mean about scuttle slope matching the bonnet line.

Paul G

Rescued attachment scuttle-line.jpg

|

|

|

RK

|

| posted on 10/10/08 at 10:21 PM |

|

|

We were doing so well until you mentioned welding. Sorry, I don't weld. But it looks very very nice.

|

|

|

Triton

|

| posted on 10/10/08 at 10:25 PM |

|

|

Make the former out of dead trees

My Daughter has taken over production of the damn fine Triton race seats and her contact email is emmatrs@live.co.uk.

www.tritonraceseats.com

www.hairyhedgehog.com

|

|

|

907

|

| posted on 10/10/08 at 11:14 PM |

|

|

quote:

Originally posted by RK

We were doing so well until you mentioned welding. Sorry, I don't weld. But it looks very very nice.

Is it not the Locostbuilders philosophy that you "do the bits you can, and get help with the bits you can't?"

A good part of the pleasure of my build is the learning of new skills, with the help of the wonderful people on this site.

No problem is insurmountable.

Paul G

|

|

|

RK

|

| posted on 11/10/08 at 09:44 PM |

|

|

Thanks. I think I'll leave everything til spring or give it to a mechanic for the winter. There are some electrical, cooling, and turbo issues

now, along with other bodywork problems that I don't have solutions for.

|

|

|